Method for treating nitro aromatic hydrocarbon substances by using carbon black limited nanogold catalyst

A technology of nitroaromatic hydrocarbons and nano-gold, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve resource waste, easy precipitation, and reuse Poor performance and other problems, to achieve the effect of reducing processing costs, accelerating mass transfer process, and promoting catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A method for treating nitroaromatics by using a carbon black-limited nano-gold catalyst, specifically using carbon black-limited nano-gold catalysts with different nano-gold particle contents to treat 4-nitrophenol (4-NP) in water , including the following steps:

[0045] Carbon black-confined nano-gold catalyst (CB / Au (1) , CB / Au (2) , CB / Au (3) , CB / Au (4) , CB / Au (5) ), 10 mg each, were added to 50 mL of 4-nitrophenol (4-NP) solution with a concentration of 0.5 mM, stirred for 30 min, and the adsorption equilibrium was reached, and 0.1 g NaBH was added 4 Solid, after fully mixed, carry out catalytic reduction reaction for 30 minutes, and complete the treatment of 4-nitrophenol.

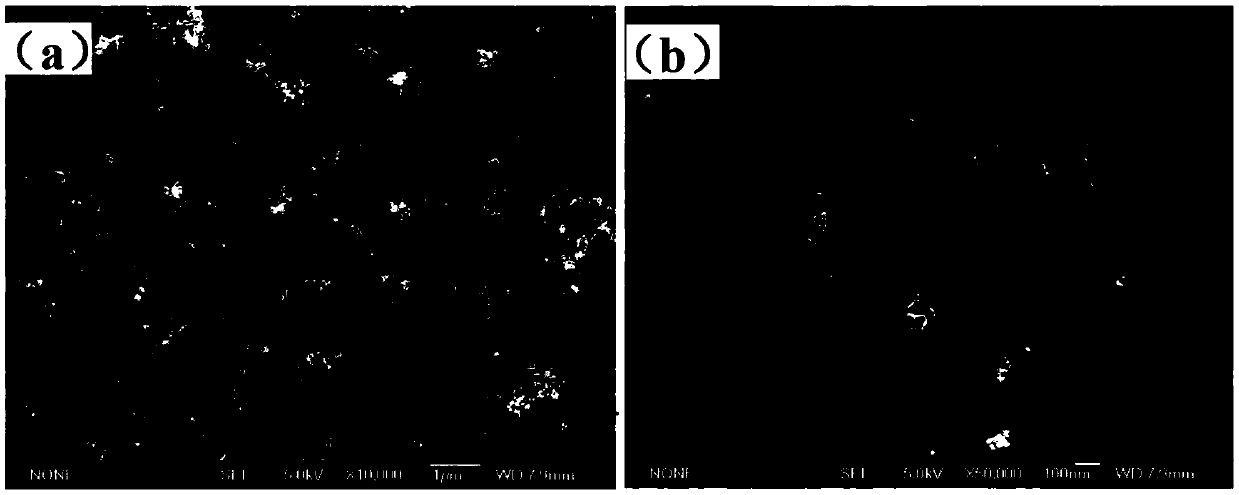

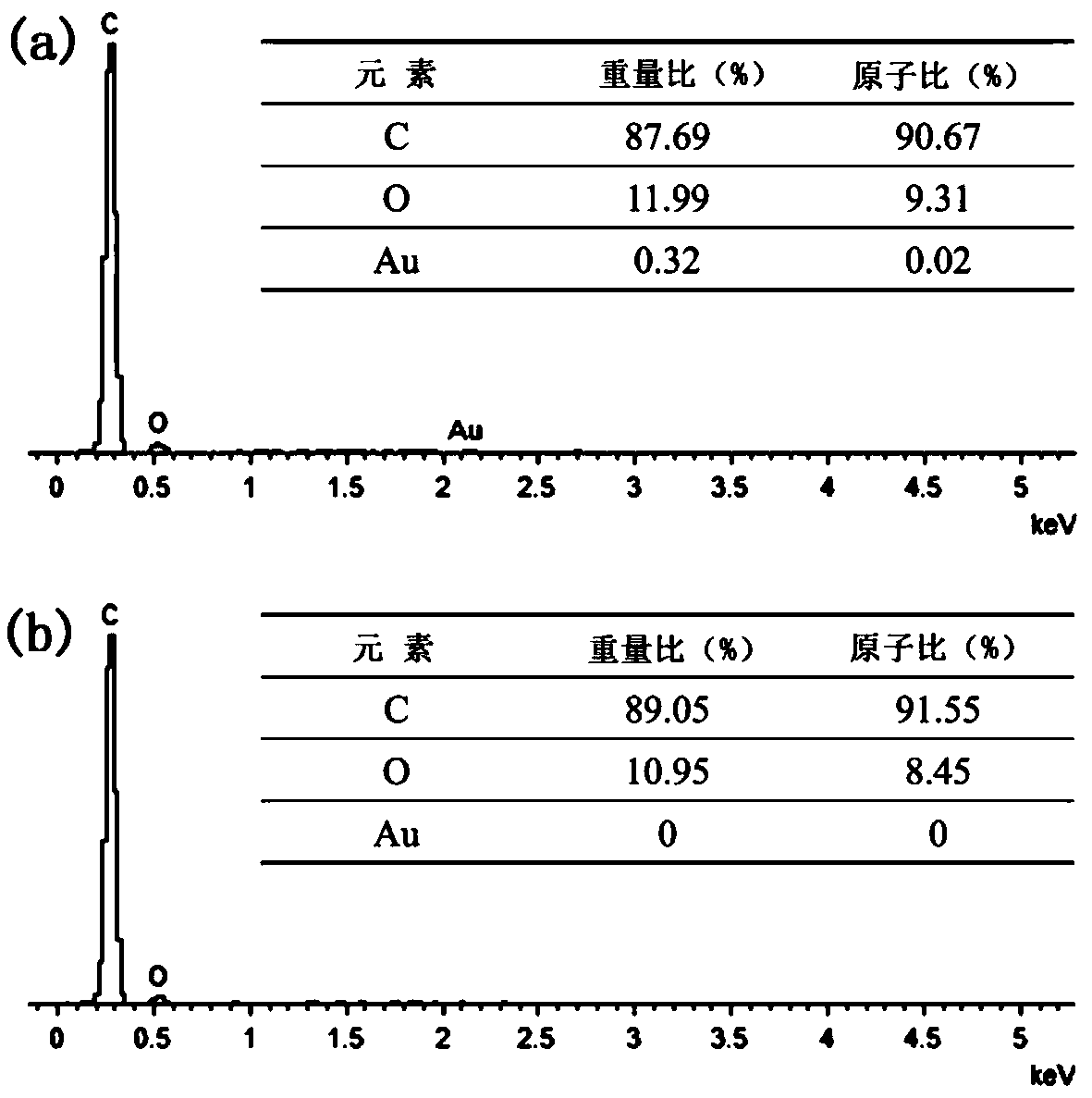

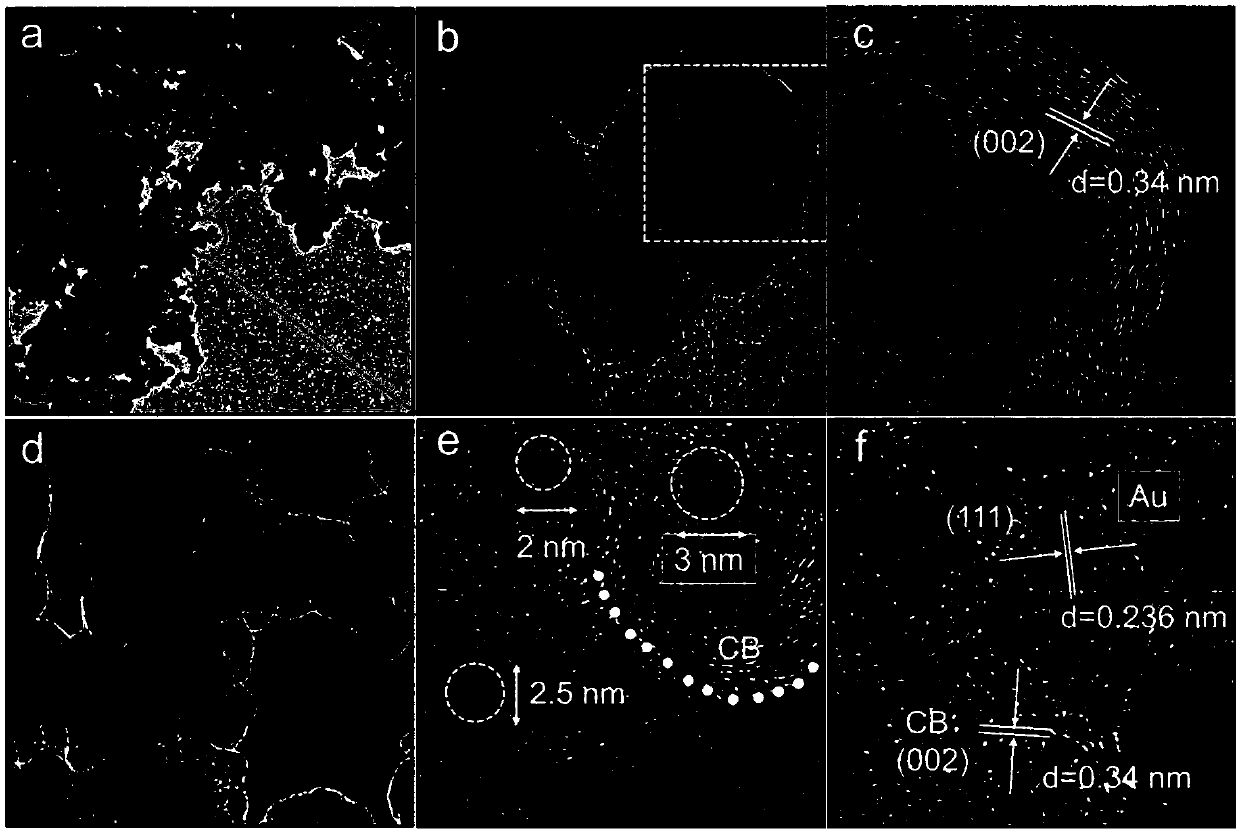

[0046] In the present embodiment, the used carbon black-limited nano-gold catalyst (CB / Au (1) ), including carbon black and nano-gold particles, wherein the nano-gold particles are fixed on the inside and surface of the carbon black, wherein the nano-gold particles are fixed in the por...

Embodiment 2

[0071] A method for treating nitroaromatic substances using a carbon black-limited nano-gold catalyst, specifically using a carbon black-limited nano-gold catalyst to separately treat 2-nitrophenol (2-NP), 3-nitro Phenol (3-NP), 2,4-nitrophenol (2,4-DNP), Congo red (CR), methyl orange (MO) and chrome black T (EBT), including the following steps:

[0072] Get the carbon black limited type nano-gold catalyst (CB / Au) prepared in embodiment 1 (3)), 10 mg each, were added to 50 mL of 2-nitrophenol (2-NP) solution, 3-nitrophenol (3-NP) solution, 2,4-nitrophenol (2,4 -DNP) solution, Congo red (CR) solution, methyl orange (MO) solution and chrome black T (EBT) solution, stirred for 30min, reached adsorption equilibrium, each added 0.1g NaBH 4 Solid, fully mixed for catalytic reduction reaction, including 2-nitrophenol (2-NP) solution, 3-nitrophenol (3-NP) solution, 2,4-nitrophenol (2,4-DNP) solution , Congo red (CR) solution, methyl orange (MO) solution and chrome black T (EBT) solu...

Embodiment 3

[0076] A method for processing nitroaromatic hydrocarbons using a carbon black-limited nano-gold catalyst, specifically using a carbon black-limited nano-gold catalyst to process 4-nitrophenol (4-NP) in water, comprising the following steps:

[0077] (1) get the carbon black limited type nano-gold catalyst (CB / Au) prepared in 10mg embodiment 1 (3) ), was added to 50mL of 4-nitrophenol (4-NP) solution with a concentration of 0.5mM, stirred for 30min, and the adsorption equilibrium was reached, and 0.1g NaBH was added 4 Solid, after mixing thoroughly, carry out catalytic reduction reaction for 5 minutes.

[0078] (2) After the reaction in step (1) is completed, the solution after the reaction is filtered, and the solid matter (carbon black-limited nano-gold catalyst) is washed with ultrapure water and sewage ethanol, dried, and the dried solid The substance (carbon black-limited nano-gold catalyst) was repeatedly treated with the 4-nitrophenol (4-NP) solution according to the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com