A Method for Predicting the Fatigue Strength of Metal Materials by Tensile Test

A technology of fatigue strength and metal materials, applied in the direction of applying stable tension/pressure to test the strength of materials, analyzing materials, strength characteristics, etc., can solve the problem of not being able to obtain the weakest sliding resistance, etc., and achieve a simple method and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] In this embodiment, a slender tensile sample is first prepared, and then the fatigue strength of the material is predicted through a tensile test. The target gauge section size of the prepared slender tensile sample is: 10 mm in length, 40 microns in width, and 40 microns in thickness.

[0050] First, two elongated tensile specimens were prepared using steps (a)-(e), and the specific preparation process was as follows:

[0051] (a) The initial sample is processed by wire electric discharge equipment, and the cross section of the initial sample is square. Sample 1 is made of maraging steel; each surface is polished with sandpaper to remove wire cutting marks; in order to achieve an ideal surface condition, the model of sandpaper is recommended to be No. 1200.

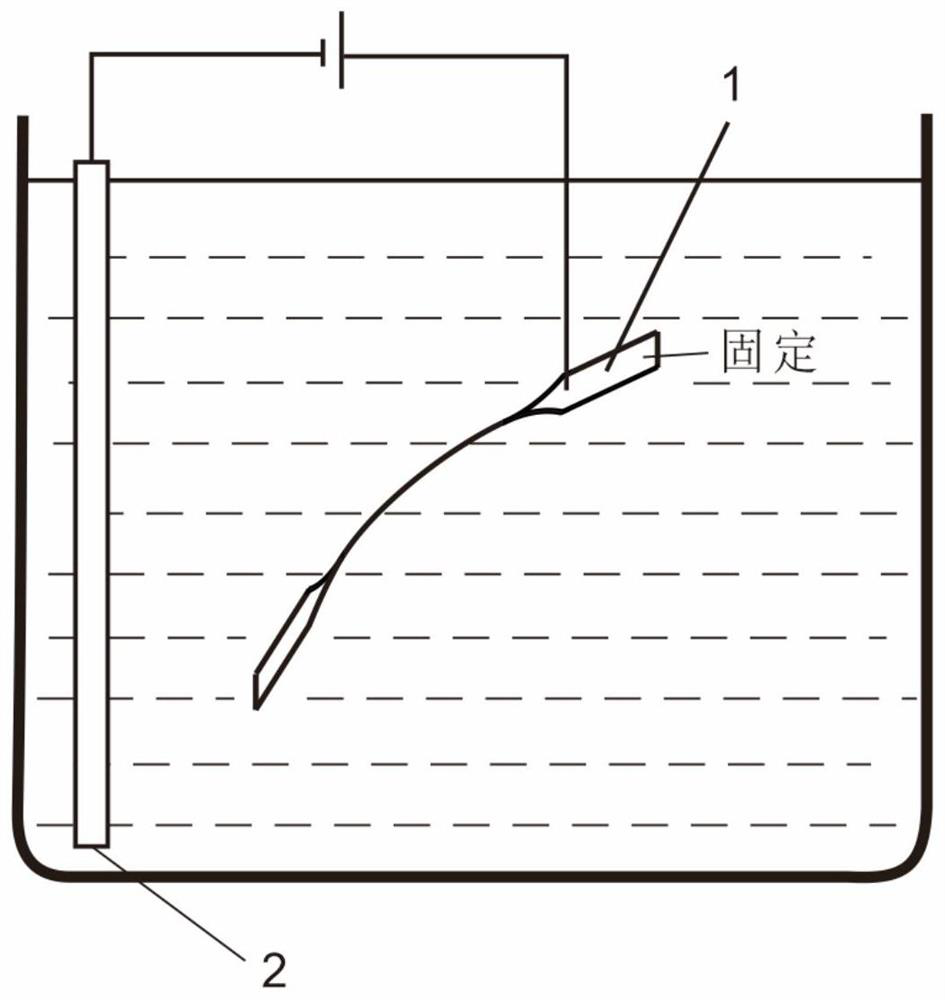

[0052] (b) According to the target size of the sample ( figure 1 ) and the density of the material to calculate the sample’s drop height h at the end of the free clamping end of the sample when the inclination angl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com