A method for recovering and preparing sodium arsenate and metal gallium from gallium arsenide waste slag

A technology of sodium arsenate and gallium arsenide, which is applied in the field of recovery and preparation of sodium arsenate and metal gallium, to achieve the effect of solving environmental pollution, waste of resources and high utilization value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

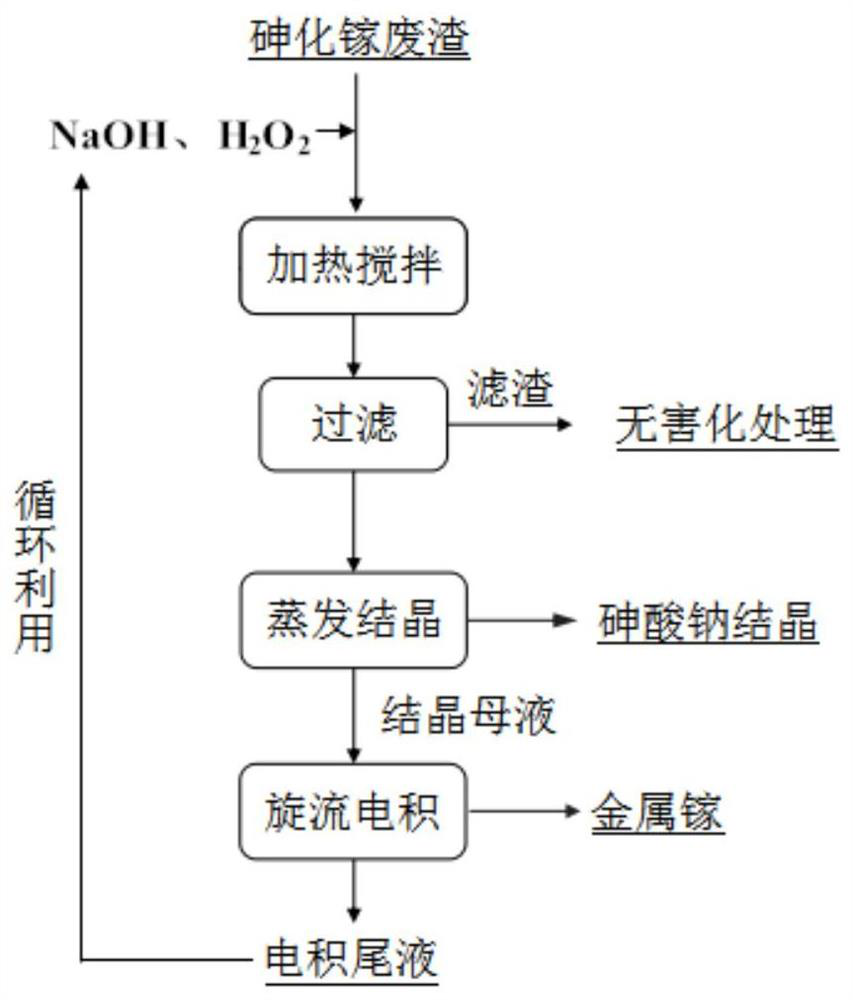

[0032] A method for recovering and preparing sodium arsenate and metal gallium from gallium arsenide waste slag, comprising the steps of:

[0033] (1) Using gallium arsenide waste slag as raw material, the gallium arsenide waste slag is a slimy gray-black massive solid, after drying at 105°C, crush it through a 100-mesh sieve, divide the waste slag into 100g / parts, and set aside ;

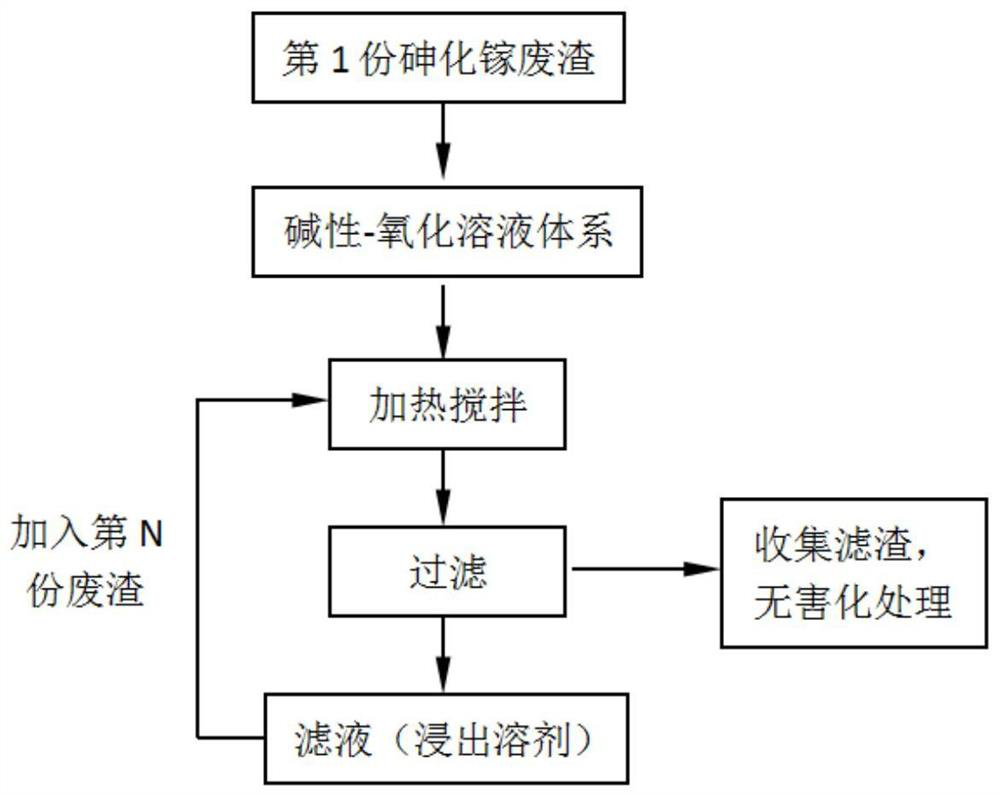

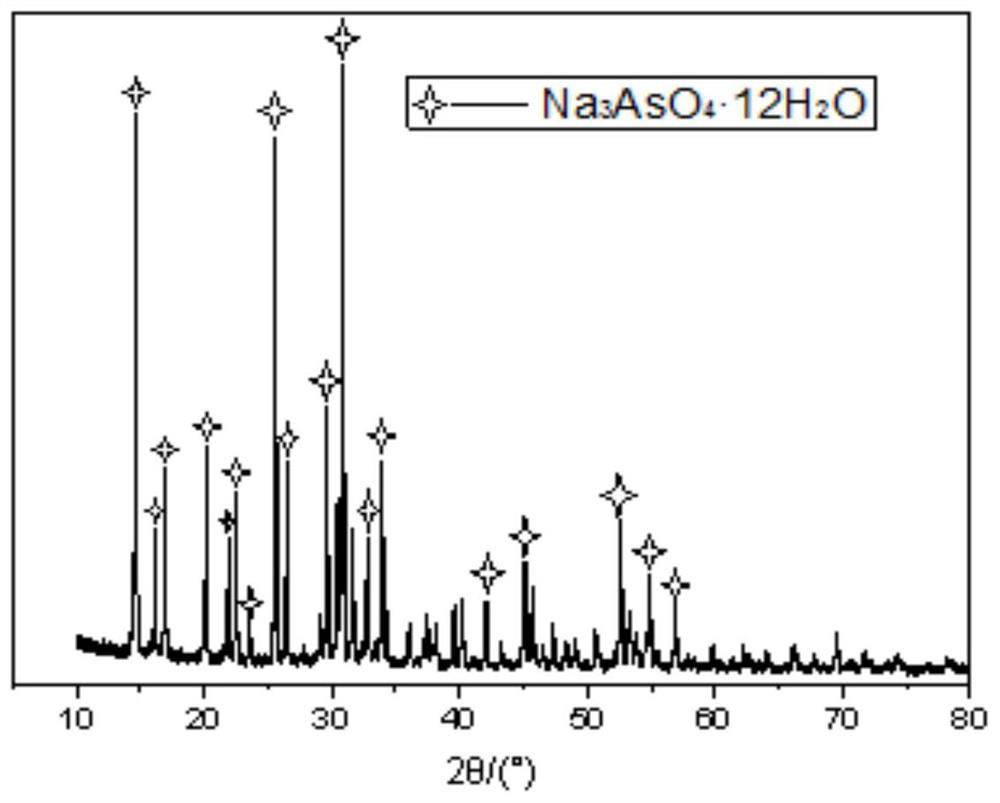

[0034] (2) Put the first part of waste residue in a 1L beaker, add 500mL of distilled water, add 40g of NaOH according to the NaOH concentration of 80g / L, heat and stir, control the stirring speed at 600rpm, control the temperature at 70°C, and follow the 80mL / L H 2 o 2 Add 40mL of hydrogen peroxide at a concentration of 10mL each time, and add in four times to form an alkaline-oxidizing solution system, so that the arsenic and gallium in the waste residue are simultaneously and rapidly dissolved in the alkaline-oxidizing solution system to form a leachate, realizing the same For the effective se...

Embodiment 2

[0041] A method for recovering and preparing sodium arsenate and metal gallium from gallium arsenide waste slag, comprising the steps of:

[0042] (1) Using gallium arsenide waste slag as raw material, the gallium arsenide waste slag is a slimy gray-black massive solid, after drying at 105°C, crush it through a 100-mesh sieve, divide the waste slag into 100g / parts, and set aside ;

[0043] (2) Put 1 part of waste residue in a 1L beaker, add 500mL of distilled water, add 50g of NaOH according to the NaOH concentration of 100g / L, heat and stir, control the stirring speed at 800rpm, and control the temperature at 70°C, according to 80mL / L of H 2 o 2 Add 40mL of hydrogen peroxide at a concentration of 10mL each time, and add in four times to form an alkaline-oxidizing solution system, so that the arsenic and gallium in the waste residue are simultaneously and rapidly dissolved in the alkaline-oxidizing solution system to form a leachate, realizing the same For the effective sepa...

Embodiment 3

[0048] A method for recovering and preparing sodium arsenate and metal gallium from gallium arsenide waste slag, comprising the steps of:

[0049] (1) Using gallium arsenide waste slag as raw material, the gallium arsenide waste slag is a slimy gray-black massive solid, after drying at 105°C, crush it through a 100-mesh sieve, divide the waste slag into 100g / parts, and set aside ;

[0050] (2) Put 1 part of waste residue in a 1L beaker, add 500mL of distilled water, add 50g of NaOH according to the NaOH concentration of 100g / L, heat and stir, control the stirring speed at 600rpm, and control the temperature at 70°C, according to the concentration of 100mL / L of H 2 o 2 Add 50mL of hydrogen peroxide at a concentration of 10mL each time, and add in five times to form an alkaline-oxidizing solution system, so that the arsenic and gallium in the waste residue are simultaneously and rapidly dissolved in the alkaline-oxidizing solution system to form a leachate, achieving the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com