A kind of graft modified natural rubber, its preparation method, rubber composition comprising graft modified natural rubber and its application

A technology of rubber composition and natural rubber latex, which is applied in transportation and packaging, special tires, tire parts, etc., and can solve the problems of less tire formula application reports, increased heat generation, and long mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In conjunction with the following specific examples, the present invention is further described in detail. The process, conditions, experimental methods, etc. for implementing the invention, except for the content specifically mentioned below, are common knowledge and common knowledge in this field, and the present invention has no special limitation content. The protection content of the present invention is not limited to the following examples. Without departing from the spirit and scope of the inventive concept, changes and advantages conceivable by those skilled in the art are all included in the present invention, and the appended claims are the protection scope.

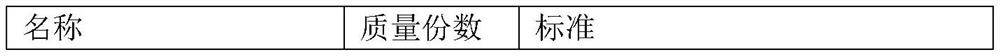

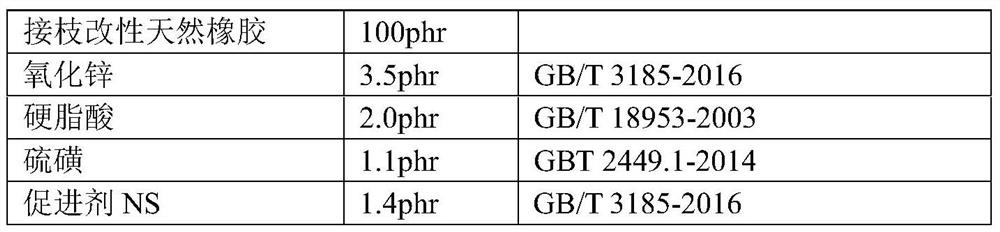

[0037] (1) In comparative examples and embodiments of the present invention, each source of material in the formula of rubber compound:

[0038] Graft modified natural rubber, self-made

[0039] Natural rubber SCR5, Yunken Jiangcheng Rubber Company

[0040] Butadiene rubber BR9000, Beijing Yanshan Pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com