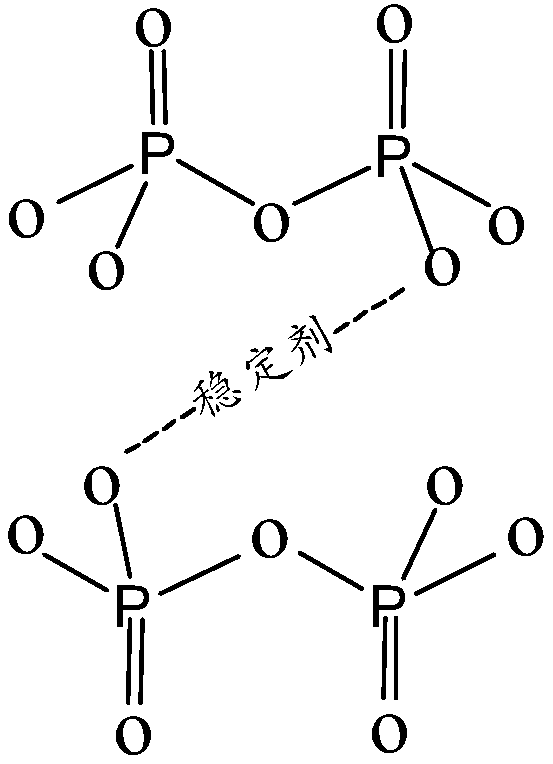

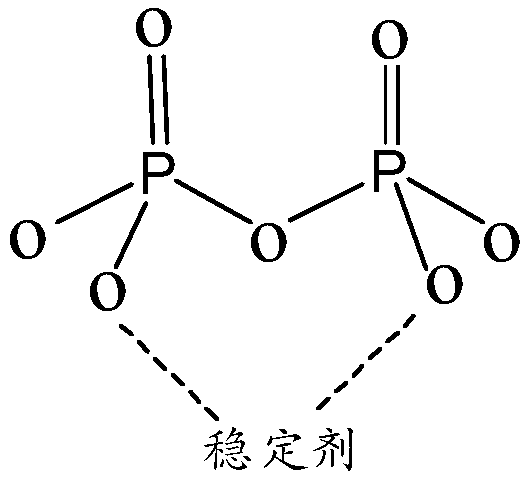

Preparation method of slow-release scale inhibitor

A scale inhibitor and slow-release technology, applied in the field of preparation of slow-release scale inhibitor, can solve the problems of difficult release rate control, uneven surface area, poor mechanical strength, etc. The effect of reducing the replacement rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] (1) Take by weighing 20.37g sodium hexametaphosphate, 0.56g calcium oxide and 0.51g aluminum oxide and mix into uniform powder;

[0053] (2) Put the powder in step (1) in a quartz crucible, then place it in a high-temperature melting furnace for reaction, gradually heat up to 700°C at a rate of 1°C / min, and stop at 300°C and 600°C respectively 30min, react at 700°C for 1h to obtain a molten reaction liquid;

[0054] (3) Pour the reaction solution obtained in step (2) into a cold water tray equipped with circulating cooling water while it is hot to obtain a fine sandy solid material, which is then filtered, dried at 120° C. for 4 hours, and ground with a mortar. And sieve to 30 mesh;

[0055] (4) Put the fine sand-like solid material into a cylindrical mold with a size of 10*15mm (diameter*height), place it in a high-temperature vacuum furnace at 700°C for 1 hour, and press 0.1pa, then take it out and cool it naturally to get the obtained product The slow release antis...

Embodiment 2

[0058] (1) Take by weighing 70.2g sodium hexametaphosphate, 3.6g calcium oxide, 3.8g magnesium oxide, 4g aluminum oxide and 0.8g silicon oxide, mix into uniform powder;

[0059] (2) Put the powder in step (1) in a quartz crucible, then place it in a high-temperature furnace for reaction, and gradually heat up to 1000°C at a rate of 3°C / min, and stay at 300°C and 600°C for 30 minutes respectively , start stirring at 850°C, rotate at 10rpm / min, react at 1000°C for 3h, and obtain a molten reaction liquid;

[0060] (3) Pour the reaction solution obtained in step (2) into a cold water tray equipped with circulating cooling water while it is hot to obtain a fine sandy solid material, filter it, dry it at 100°C for 6 hours, and grind it with a mortar. And sieve to 20 mesh;

[0061] (4) Put the sieved material into a cylindrical mold with a size of 7*10mm (diameter*height), place it in a high-temperature vacuum furnace at 1000°C for 0.5h, and press at 0.1pa, then take it out and let ...

Embodiment 3

[0064] (1) Take by weighing 61.12g sodium hexametaphosphate, 4.48g calcium oxide, 4g magnesium oxide, 1.02g aluminum oxide and 0.6g silicon oxide, mix into uniform powder;

[0065] (2) Put the powder in step (1) in a quartz crucible, then place it in a high-temperature furnace for reaction, gradually heat up to 1000°C at a rate of 4°C / min, and stay at 300°C and 600°C for 30 minutes respectively , start stirring at 850°C, rotate at 8rpm / min, react at 1000°C for 3.5h, and obtain a molten reaction liquid;

[0066] (3) Pour the reaction solution obtained in step (2) into a cold water tray equipped with circulating cooling water while it is hot to obtain a fine sandy solid material, which is then filtered, dried at 120° C. for 4 hours, and ground with a mortar. And sieve to 30 mesh;

[0067] (4) Put the screened material into a cylindrical mold with a size of 5*8mm (diameter*height), place it in a high-temperature vacuum furnace at 1000°C for 2 hours, and press 0.1pa, then take it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com