A preparation method of surface-treated ZTA particle-reinforced steel-based composite grinding roller

A particle enhancement and surface treatment technology, used in vacuum evaporation plating, coating, sputtering plating, etc., can solve the problems of low bonding strength, affecting the large-scale application of wear-resistant parts, poor bonding, etc., and achieve enhanced interface bonding performance, ensuring service safety, high bonding and impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] A method for preparing a surface-treated ZTA particle-reinforced steel-based composite grinding roller of the present invention comprises the following steps:

[0038] S1. Soak the ZTA particles in acetone for 15-30 minutes, pickle them, then wash them with acetone for 8-20 minutes by ultrasonic waves, rinse them with deionized water, and dry them;

[0039] S2, ZTA and SiO after drying 2 Put the small particles into the ball mill for low-speed ball milling for 10-40min, and the ball-milling speed is 60-180r / min, so that the surface of the ZTA particles is micro-roughened, increasing the attachment points of Cr in the subsequent multi-arc ion plating process, and improving the surface of ZTA. The plating efficiency is high, then filter the ZTA particles with a 10-50 mesh sieve, and clean them with alcohol;

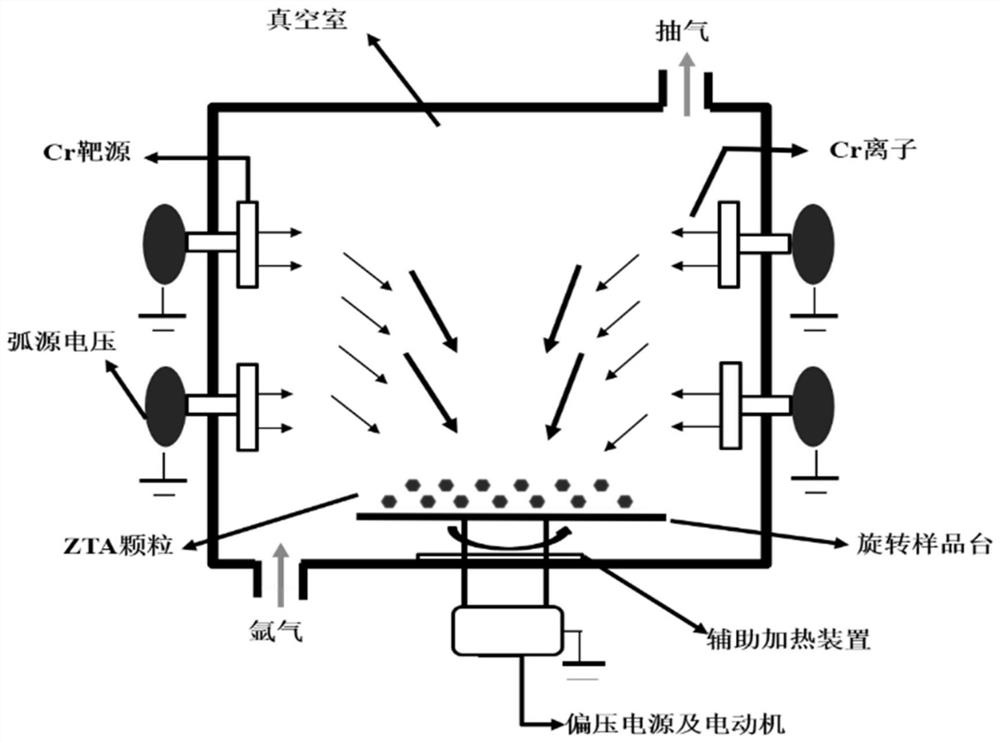

[0040]S3. Use the method of multi-arc ion plating to plate metal chromium on the surface of ZTA particles, use the method of arc discharge, use the chromium target ...

Embodiment 1

[0051] 1) First, soak ZTA in acetone for 15 minutes, pickle the ZTA particles, then clean them with acetone for 10 minutes by ultrasonic waves, wash them with deionized water, and dry the treated ZTA particles in a vacuum drying oven;

[0052] 2) Secondly, the dried ZTA and SiO 2 Put the small particles into a 60r / min planetary ball mill for 10 minutes of low-speed ball milling, and then filter the ZTA particles with a 10-mesh sieve;

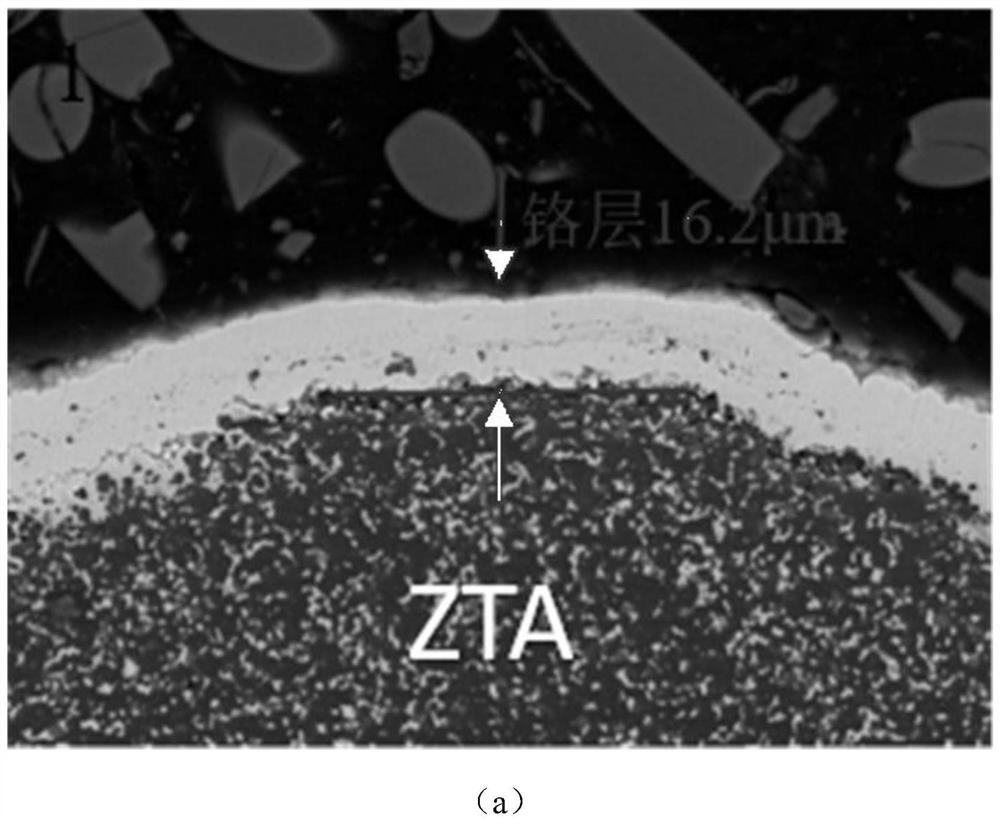

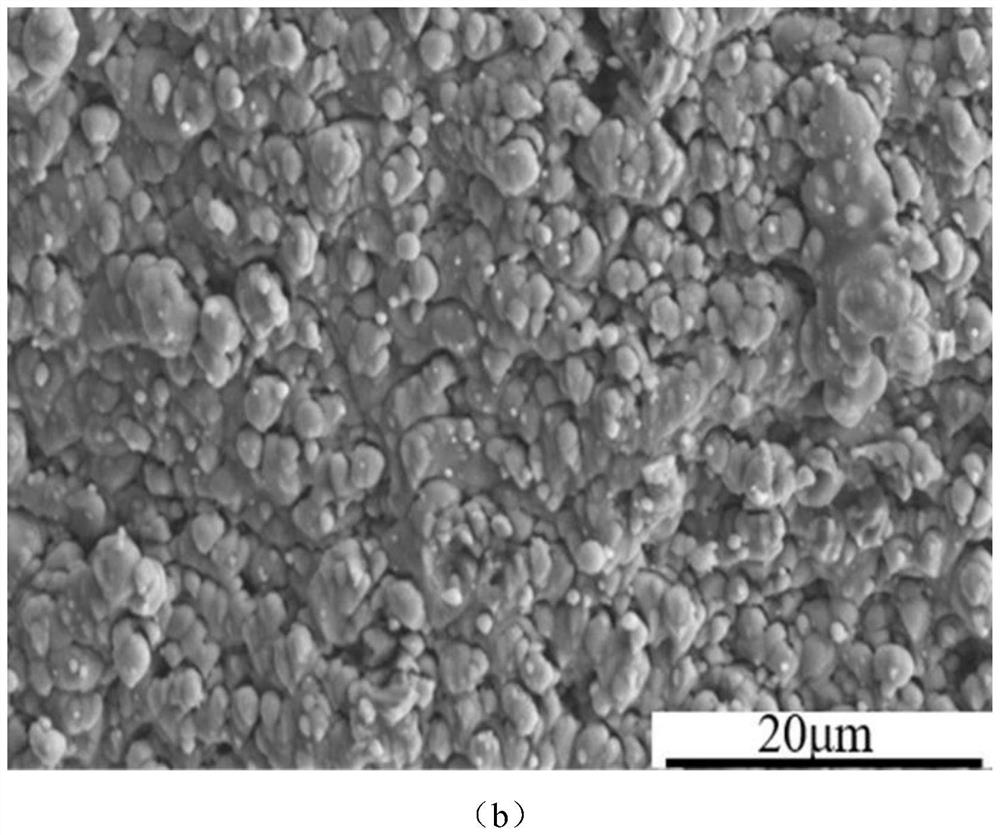

[0053] 3) Subsequently, metal chromium was plated on the surface of the dried ZTA particles by multi-arc ion plating, and the vacuum degree of the arc discharge deposition chamber was selected for the plating process to be about 7.0×10 -3 Pa, the substrate temperature is about 40°C, the bias voltage of multi-arc ion plating is 100V, the duty cycle is 50%, the current size is 50A, the plating time is 30min, and the thickness of the Cr layer is 9.6μm;

[0054] see figure 1 , figure 1 It is a cross-sectional view of the multi-arc ion plating vac...

Embodiment 2

[0059] 1) First soak ZTA in acetone for 18 minutes, pickle the ZTA particles, then clean them with acetone for 12 minutes by ultrasonic waves, wash them with deionized water, and dry the treated ZTA particles in a vacuum drying oven;

[0060] 2) Secondly, the dried ZTA and SiO 2 Put the small particles into an 80r / min planetary ball mill for 15 minutes of low-speed ball milling, and then filter the ZTA particles with a 15-mesh sieve;

[0061] 3) Subsequently, metal chromium was plated on the surface of the dried ZTA particles by multi-arc ion plating, and the vacuum degree of the arc discharge deposition chamber was selected for the plating process to be about 8.0×10 -3 Pa, the substrate temperature is about 45°C, the bias voltage of multi-arc ion plating is 110V, the duty cycle is 55%, the current is 55A, and the plating time is 40min;

[0062] 4) Put the ZTA particles pre-coated with Cr layer into alcohol for ultrasonic cleaning for 18 minutes, then uniformly mix the ZTA pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com