Continuous casting device for hypereutectic aluminum-silicon alloy and manufacturing method thereof

An aluminum-silicon alloy and hypereutectic technology, which is applied in the field of metal material preparation and application, can solve problems such as difficulties, and achieve the effects of uniform distribution, cost reduction, and uniform temperature field and composition field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

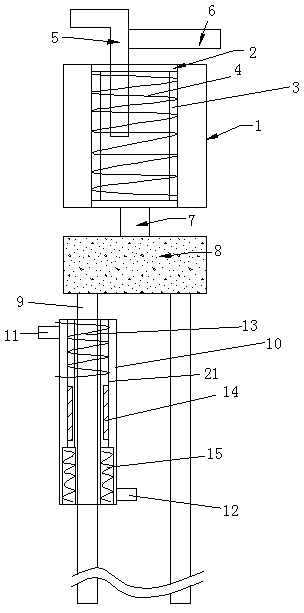

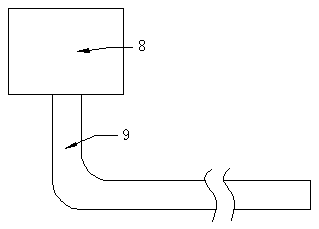

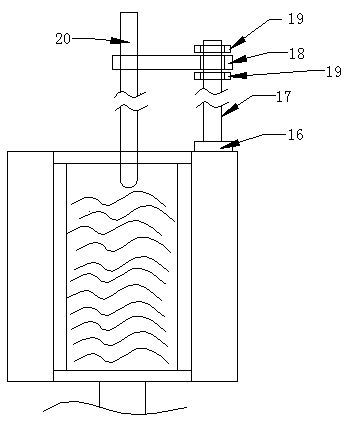

[0022] like figure 1 , figure 2 , image 3 and Figure 4 The shown continuous casting device for hypereutectic aluminum-silicon alloy consists of a molten pool assembly and an electromagnetic stirring assembly used in conjunction with the molten pool assembly; the molten pool assembly includes a casing 1 and is arranged on the casing 1 The vacuum melting furnace 2 inside, and the rotating electromagnetic stirring hollow shell 3 arranged on the inner wall of the vacuum melting furnace 2, and the charged coil 4 arranged in the rotating electromagnetic stirring hollow shell 3, and the solution conduit 7 arranged at the bottom of the shell 1 ; The electromagnetic stirring assembly includes a transition molten pool 8 connected to the conduit 7, and several L-shaped solution feeding pipes 9 arranged at the bottom of the transition molten pool 8, and several L-shaped solution feeding pipes 9 arranged respectively The hollow outer shell 10 on the top, the hollow inner shell 21 arr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com