Oral nano-vaccine of large yellow croaker and immune type large yellow croaker feed prepared by the same

A nano-vaccine, large yellow croaker technology, applied in vaccines, veterinary vaccines, pharmaceutical formulations, etc., can solve the problems of inability to achieve immune effects, affect immune protection effects, etc., achieve cost-effective, reduce toxicity and stimulation, and biocompatibility Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

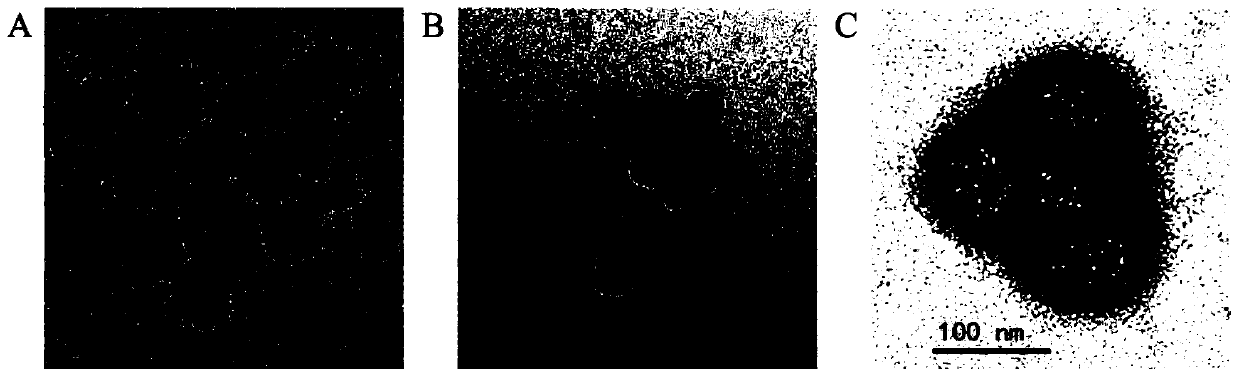

Image

Examples

preparation example Construction

[0026] The preparation method of described large yellow croaker oral nano-vaccine, it comprises the following processing steps:

[0027] (1) preparing MSN nanoparticles;

[0028] The specific method of step (1) is: add hexadecyltrimethyl-p-toluenesulfonate amine, triethanolamine and water into a round bottom flask, stir and dissolve at 80-85°C for 1-2h; then quickly add tetrasilicic acid Ethyl ester, continue stirring for 2-3h; centrifuge at 12745g for 20-25min to recover the precipitate; use ddH for precipitation 2 Wash twice with O, followed by 6 g / L NH at 60-65 °C 4 NO 3 The methanol solution extracted the product 3 times; after the extraction, the precipitate was recovered by centrifugation at 12745g for 20-25min, and the 2 O washed and precipitated 2 times, and the precipitate was dried at normal temperature to obtain the MSN nanoparticles.

[0029] (2) Preparation of MSN-DLDH nanoparticles: resuspend the MSN nanoparticles obtained in step (1) in ddH 2 In O, form the...

Embodiment 1

[0041] Embodiment 1: Preparation of oral nano-vaccine of large yellow croaker:

[0042] (1) Preparation of MSN nanoparticles: Add 4.8g of cetyltrimethyl-p-toluenesulfonate, 0.7mL of triethanolamine and 250mL of water into a round bottom flask, stir and dissolve at 80°C for 1h; then quickly add 10mL of silicic acid Tetraethyl ester, continue to stir and react for 2h; centrifuge at 12745g for 20min to recover the precipitate; use ddH for precipitation 2 Washed twice with O, followed by 6 g / L NH at 60 °C 4 NO 3 The methanol solution extracted the product 3 times; after the extraction, the precipitate was recovered by centrifugation at 12745g for 20min, and the 2 O washed and precipitated 2 times, and the precipitate was dried at normal temperature to obtain the MSN nanoparticles.

[0043] (2) Preparation of MSN-DLDH nanoparticles: resuspend the MSN nanoparticles obtained in step (1) in 20mL ddH 2 In O, the MSN nanoparticle suspension liquid that obtains concentration is 23.2m...

Embodiment 2

[0048] Embodiment two: the preparation of immune type large yellow croaker feed:

[0049] Resuspend the MSN-DLDH@HP55 enteric-coated nanoparticles obtained in step (3) of Example 1 in 200mL ddHO 2 In O, a suspension of MSN-DLDH@HP55 enteric nanoparticles with a concentration of 1.77mg / mL was formed;

[0050] MSN-DLDH@HP55 vaccine mix: Next, mix 2kg of large yellow croaker No. 2 feed with 3g of adhesive, and then evenly spray MSN-DLDH@HP55 enteric-coated nanoparticle suspension on the surface of large yellow croaker No. 2 feed Stir evenly again, spray 1mL of MSN-DLDH@HP55 enteric-coated nanoparticle suspension per 20g of large yellow croaker No. 2 feed, and then vacuum freeze-dry at -30°C to obtain feed with MSN-DLDH@HP55 attached. The feed with MSN-DLDH@HP55 was soaked in the chitosan solution for 3 seconds to form a thin coating (the chitosan solution should not cover the feed with MSN-DLDH@HP55 during soaking), and quickly transferred to ddH 2 Soak in O for 5s and take out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com