Preparation method of washable and wearable high-sensitivity pressure sensor

A pressure sensor, capacitive technology, applied in nanotechnology for sensing, fluid pressure measurement using capacitance changes, instruments, etc., can solve the problems of low sensitivity and cumbersome preparation steps of capacitive pressure sensors, and achieve medium Regular and uniform electrical layer, simple process and fast response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

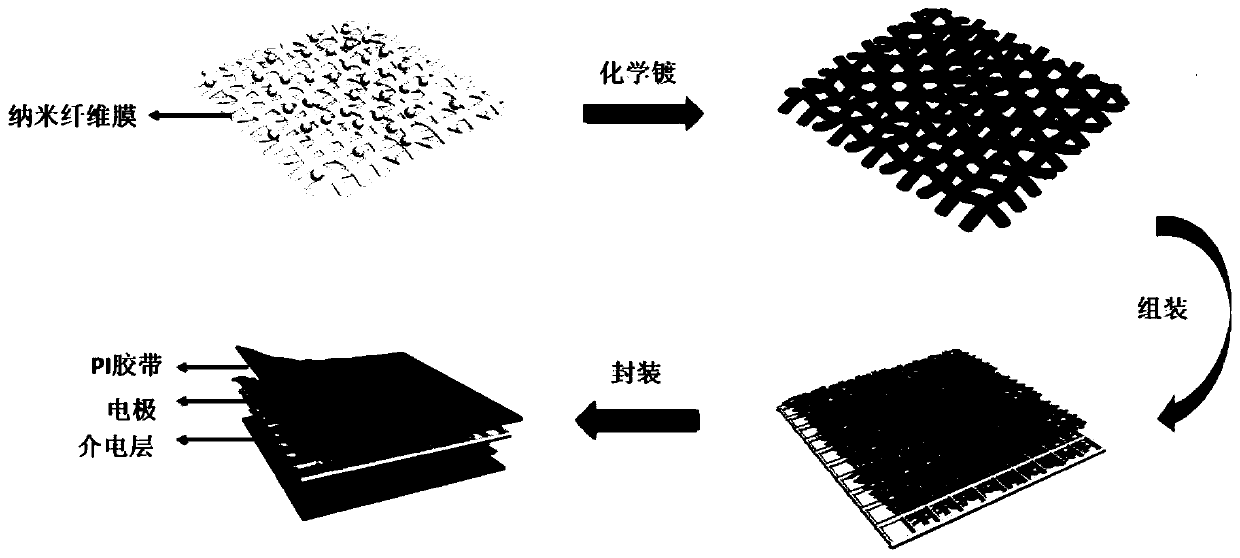

Embodiment 1

[0031] (1) Take 0.17mgPdCl 2 Prepare a 1.7ppm solution with 100ml of DMF, then take 0.8g of PAN powder and dissolve it in 10ml of palladium solution to obtain a spinning solution, add the spinning solution into the syringe, set certain spinning parameters for spinning, and set the diameter of the nozzle 0.67mm, the receiving distance is 15cm, the advancing speed is 6.5ml / h, the applied voltage is 18kv, and the electrospinning time is 10h to obtain the nanofiber membrane.

[0032] (2) Dissolve 1.5 g of glucose and 60 mg of polyethylene glycol with 3 ml of ethanol and 47 ml of deionized water to prepare 50 ml of reducing solution. With 0.8g silver nitrate (AgNO 3 ) and deionized water to configure 8g / L AgNO 3 solution, add ammonia water (about 0.6ml) dropwise until the solution becomes clear from turbidity to obtain a silver ammonia solution, and then add 1ml of ethylenediamine. First immerse the nanofiber membrane into the reducing solution, then quickly pour it into the sil...

Embodiment 2

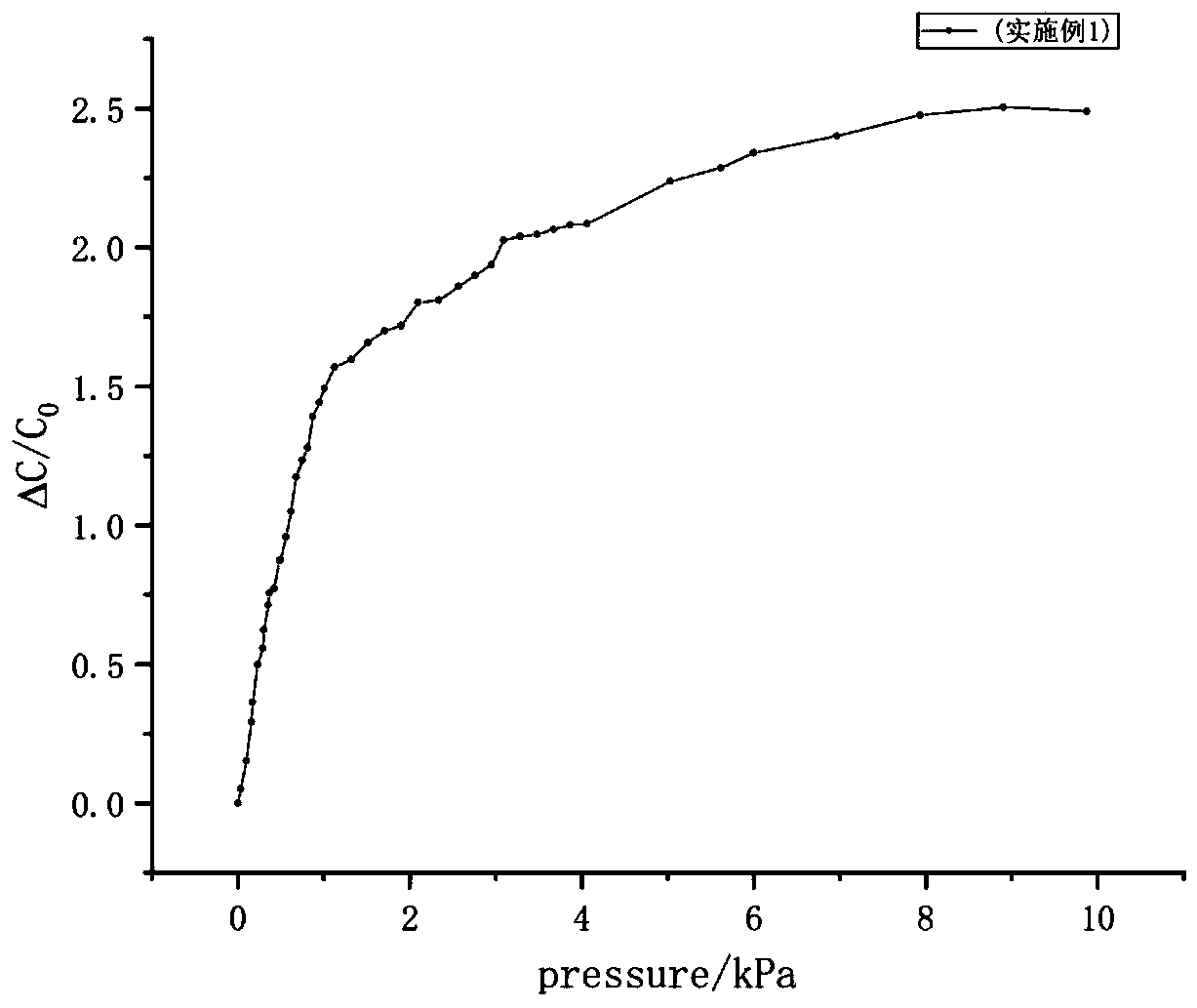

[0035] According to Example 1, the time of electroless plating under ultrasound in step (2) of Example 1 was changed to 30 minutes, and the rest were the same as in Example 1 to obtain a capacitive pressure sensor. Test the capacitance value of the sensor, and calculate the sensitivity through the sensitivity S=dΔC / dP, and the sensitivity is shown in Table 1.

Embodiment 3

[0037] The electrodes and dielectric layer of the capacitive pressure sensor in Example 1 were disassembled and washed with water, first ultrasonically washed for 2 minutes, then dried, and cycled 10 times, and then assembled according to Example 1 to obtain a capacitive pressure sensor. The capacitance value of the sensor was tested, the sensitivity was calculated by the sensitivity S=dΔC / dP, and the performance change after washing was detected as shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com