Heat exchanger and condensing boiler

A technology for heat exchangers and heat exchange tubes, applied in the field of boilers, can solve problems such as difficulties in heat exchanger design, processing, and mass production, increase in material use costs and processing costs, and slow progress in the transformation process of condensation technology, achieving reduction probability, lower flue gas temperature, and improve heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

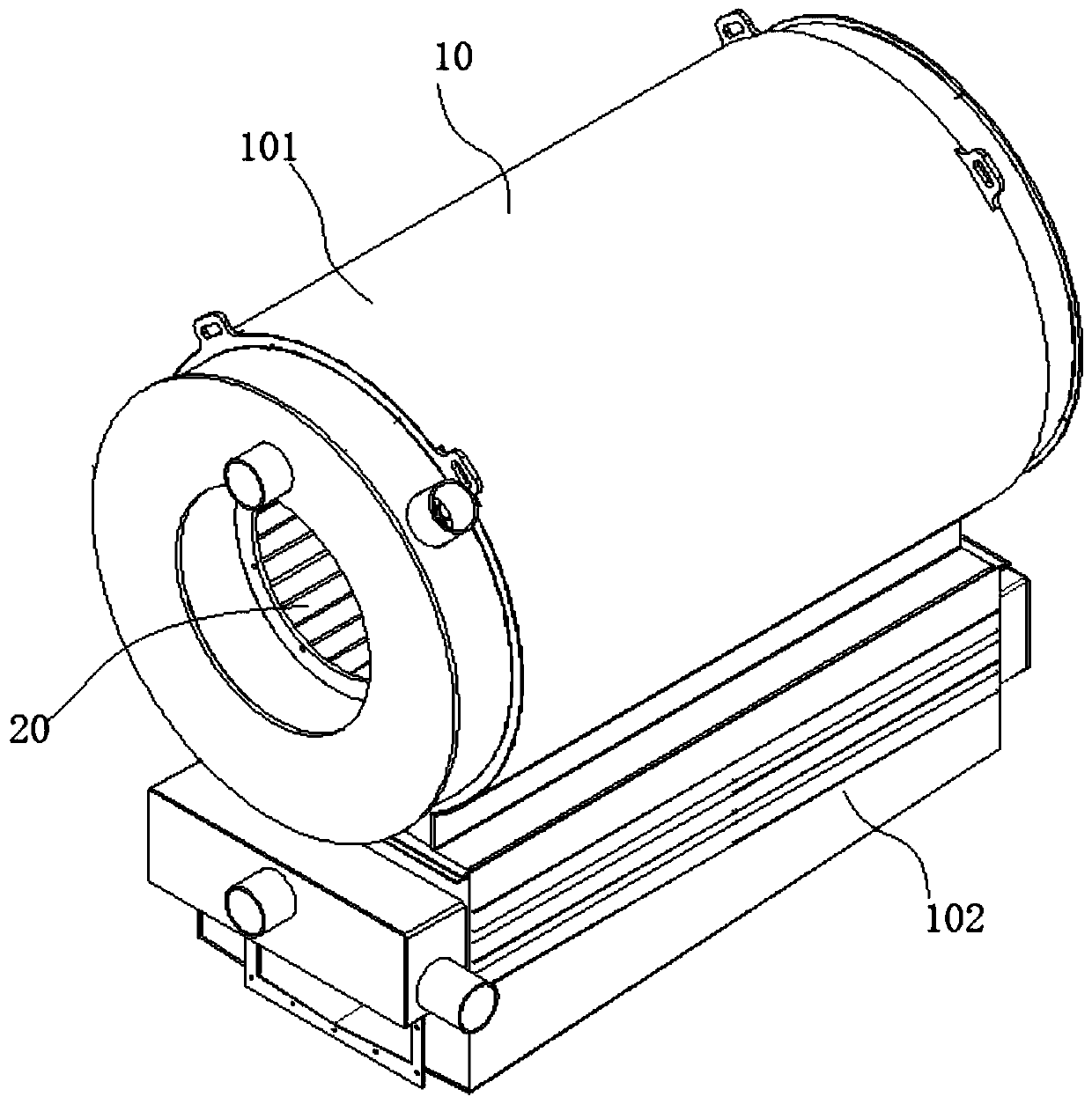

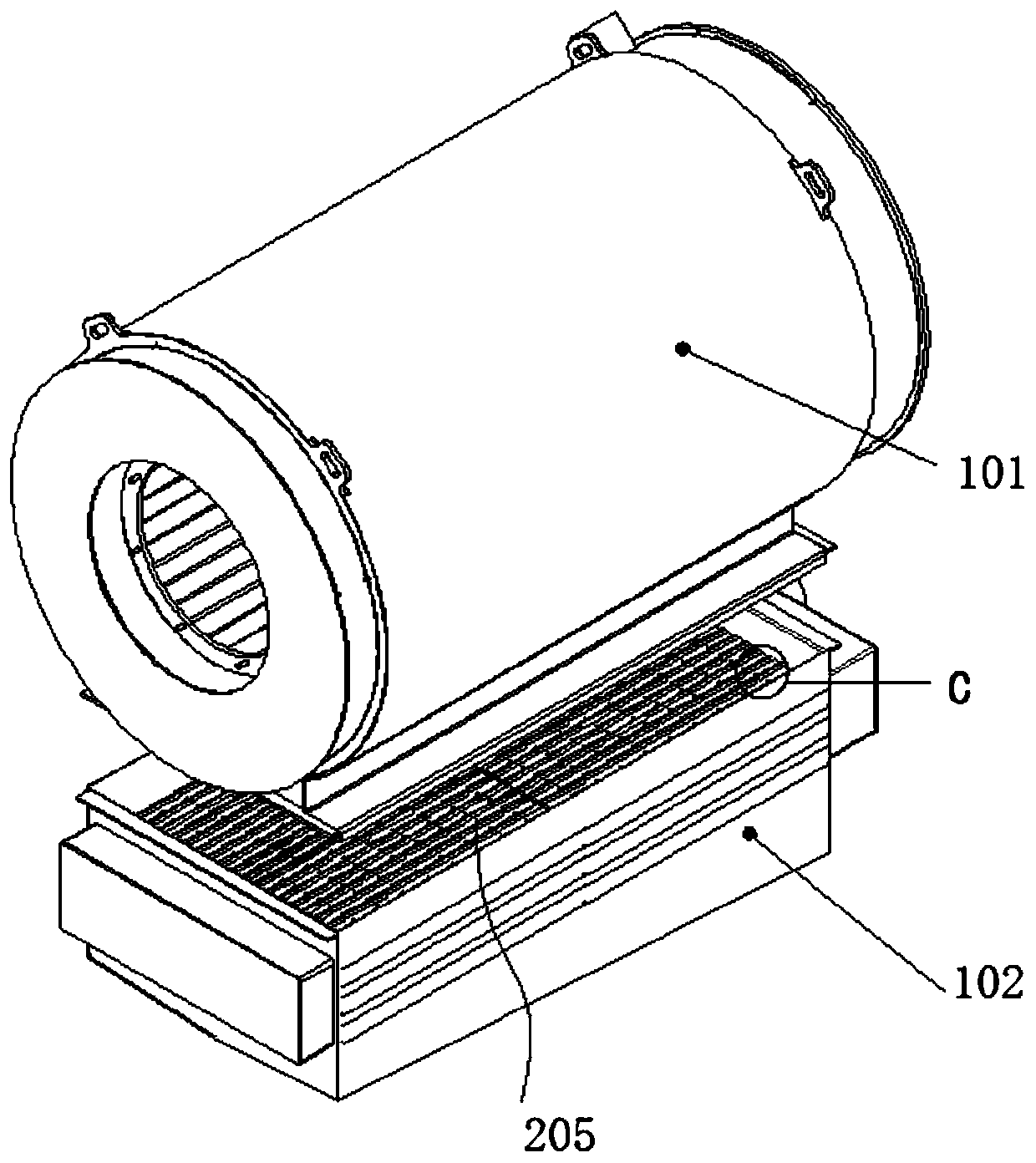

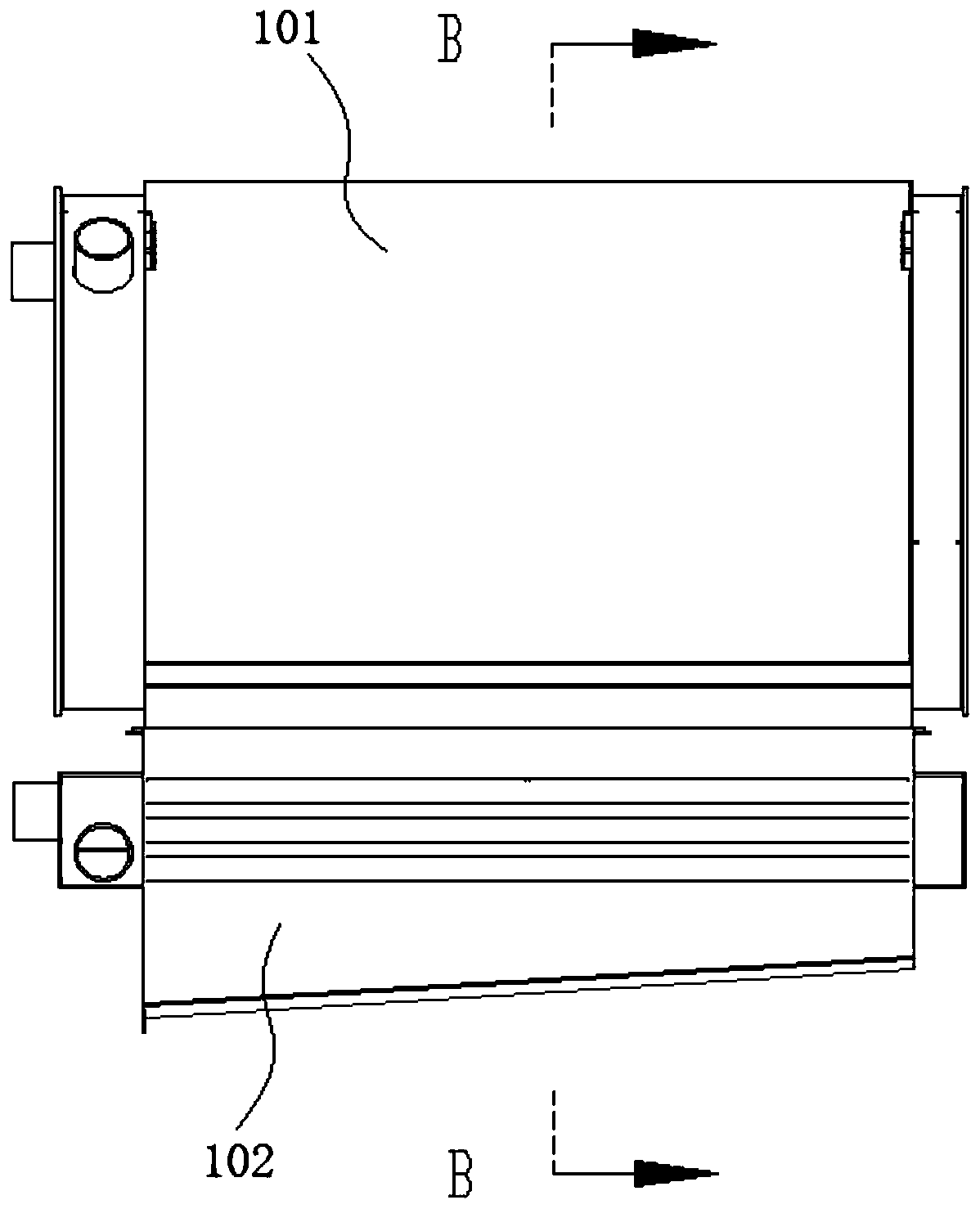

[0050] see Figure 1 to Figure 9 , figure 1 is a schematic structural view of a condensing boiler provided by an embodiment of the present invention;

[0051] figure 2 yes figure 1 Schematic diagram of the separation of the upper and lower structures; image 3 yes figure 1 The schematic diagram of the main view; Figure 4 yes image 3 Right view diagram; Figure 5 yes image 3 The left view schematic diagram of ; Figure 6 yes Figure 5 A schematic cross-sectional view of A; Figure 7 yes image 3 B-direction cross-sectional schematic diagram; Fig. 8(a) is figure 2 Figure 8(b) is a schematic diagram of the cross-sectional structure of the outer heat exchange tube of the present invention in an embodiment; Figure 8(c) is an embodiment of the inner heat exchange tube of the present invention Schematic diagram of the cross-sectional structure in the example; Figure 9 yes figure 2 The enlarged schematic diagram of the second deflector in the middle.

[0052] like...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com