A high specific surface area transition metal powder and its preparation method

A high specific surface area, transition metal technology, used in metal processing equipment, transportation and packaging, etc., can solve problems such as high cost, complex process, and easy agglomeration of nanoparticles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

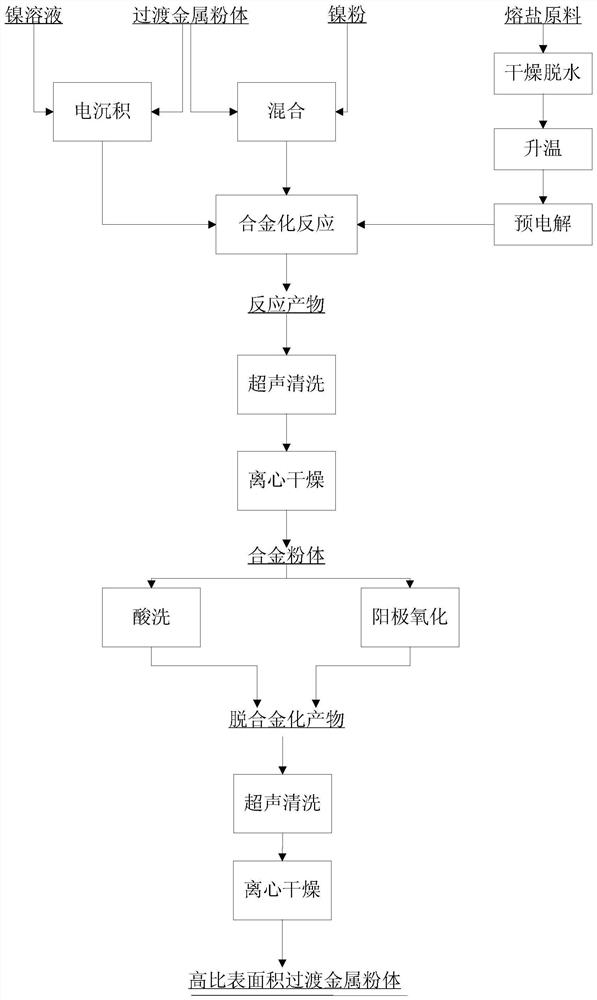

[0057] A kind of preparation method of transition metal powder with high specific surface area, its flow chart is shown in figure 1 , including the following steps:

[0058] 1. Mix metal Ta and nickel powder according to the molar ratio of Ta:Ni=1:2, and mix evenly to obtain a mixture of transition metal Ta and nickel.

[0059] 2. According to the proportion, weigh 400g of KCl-NaCl molten salt as the molten salt raw material, put the dried and dehydrated molten salt raw material in an alumina crucible, place it in a sealed reactor, protect it with an inert gas, and raise the temperature to 800°C. Apply a voltage of 2.8V, pre-electrolyze for 3 hours, remove impurities such as metal ions in the molten salt, and obtain a molten salt system after pre-electrolysis.

[0060] 3. Immerse the mixture of transition metal Ta and nickel into the molten salt, keep the temperature at 800° C. for 10 hours, carry out alloying reaction, and obtain the reaction product.

[0061] The reaction ...

Embodiment 2

[0065] A kind of preparation method of high specific surface area transition metal powder, with embodiment 1, difference is:

[0066] In step 1, metal Ta and nickel powder are evenly mixed according to the molar ratio of Ta:Ni=1:8;

[0067] Other embodiments are the same, the specific surface area of the high specific surface area transition metal powder obtained is 6.8m 2 / g.

Embodiment 3

[0069] A kind of preparation method of high specific surface area transition metal powder, with embodiment 1, difference is:

[0070] In step 3, the temperature is raised to 900° C., and the temperature is kept constant for 5 hours to carry out alloying reaction;

[0071] Other implementations are the same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com