A kind of composite polymer laminated fabric and its preparation method

A composite polymer and laminated fabric technology, applied in the field of laminated fabrics, can solve the problems of flexibility, strength, wear resistance, performance weakening, etc., to improve adhesion, enhance scratch resistance, improve The effect of reinforcing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

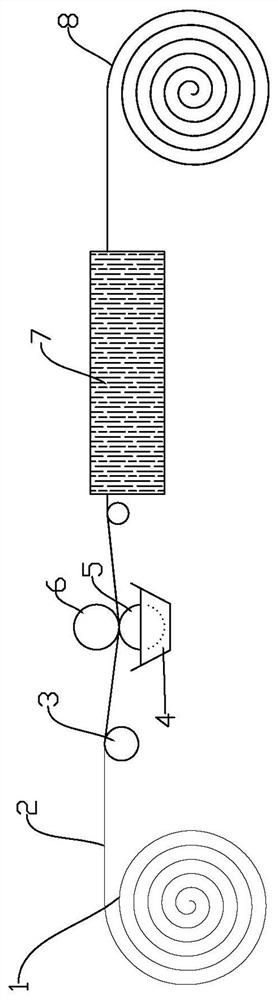

Image

Examples

Embodiment 1

[0052] A composite polymer laminated fabric, comprising a fabric substrate layer, a 100 μm substrate melt adhesive layer, an adhesive layer and a 0.2mm composite polymer layer. The substrate melting layer is composed of part of the fabric structure of the fabric substrate and the adhesive intersecting, and the fabric structure in the fabric substrate layer is integrated with the fabric structure in the substrate melting layer; the adhesive layer and the substrate The glue-melt layer forms an integral body; the composite polymer layer is pasted on the fabric substrate layer through the adhesive layer.

[0053] In this embodiment, the fabric base material is made of polyester yarns through plain weaving process.

[0054] The composite polymer layer includes the following components in parts by mass:

[0055] EVA resin 25

[0056] PP20

[0057] PE-g-MAH 5

[0058] TPU 15

[0059] Superfine Calcium Carbonate 22

[0060] Release agent 1

[0061] Colorant 2.

[0062] In the ...

Embodiment 2

[0074]The laminated fabrics of this embodiment are substantially the same as those of the preferred embodiment, except that their fabric substrates are slightly different, their calendered layer formulations are slightly different, and their adhesive formulations are slightly different.

[0075] Specifically, the fabric substrate layer is a blended fabric of PET and nylon composite fibers, and the weave is a plain weave.

[0076] In this embodiment, the thickness of the part of the adhesive layer that is thermally pressed into the fabric tissue of the fabric substrate layer is 50 μm. In the pasting process, the pressure of the roller press is 0.5MPa, and the vehicle speed is 35m / min. The amount of glue applied to the adhesive is 100g / m 2 . The yarn denier of the fabric substrate is 600D.

[0077] The adhesive layer adopts a roller coating process, the viscosity of the adhesive is 5000cps, the glue coating temperature is room temperature, and the controlled glue amount is 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com