Six-arm star-shaped amphiphilic polymer and preparation method thereof, and nano hydrogel drug-loading system prepared from six-arm star-shaped amphiphilic polymer

An amphiphilic polymer and polymer technology, which can be used in organic active ingredients, medical preparations with non-active ingredients, and medical preparations containing active ingredients, etc., can solve problems such as responsive exploration, and achieve simple operation and high performance pH-responsive, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

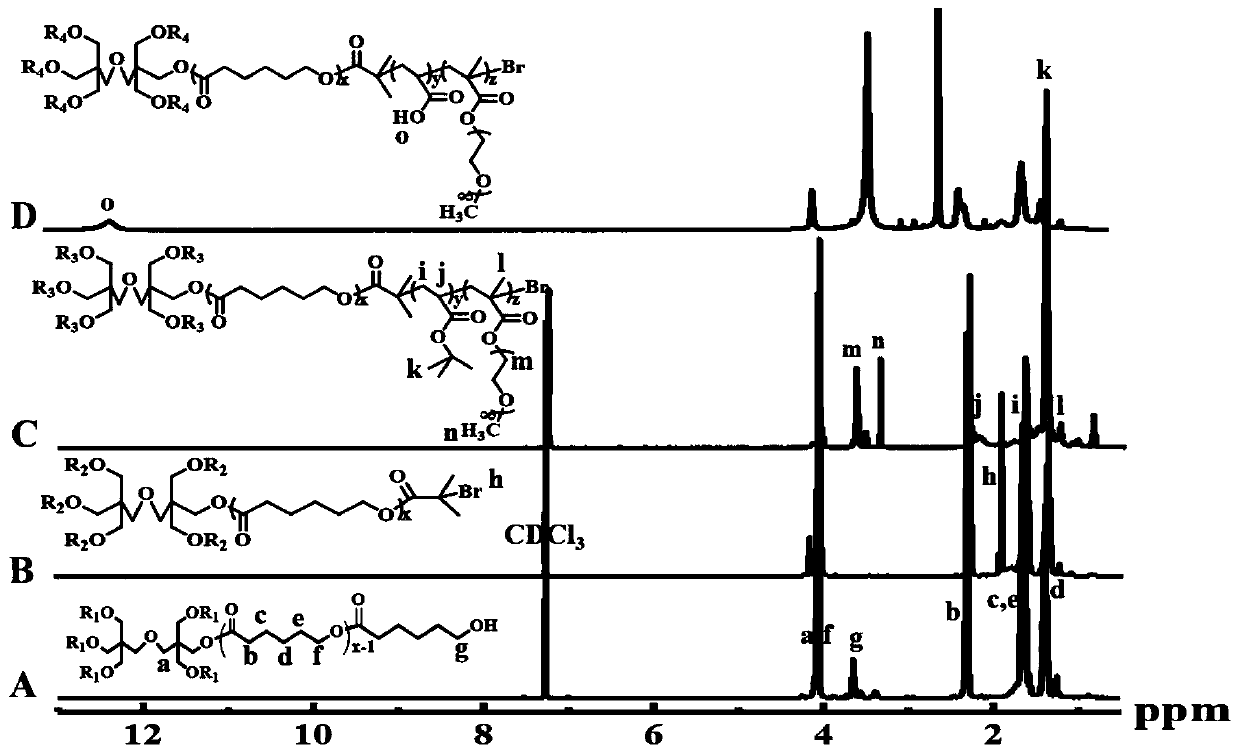

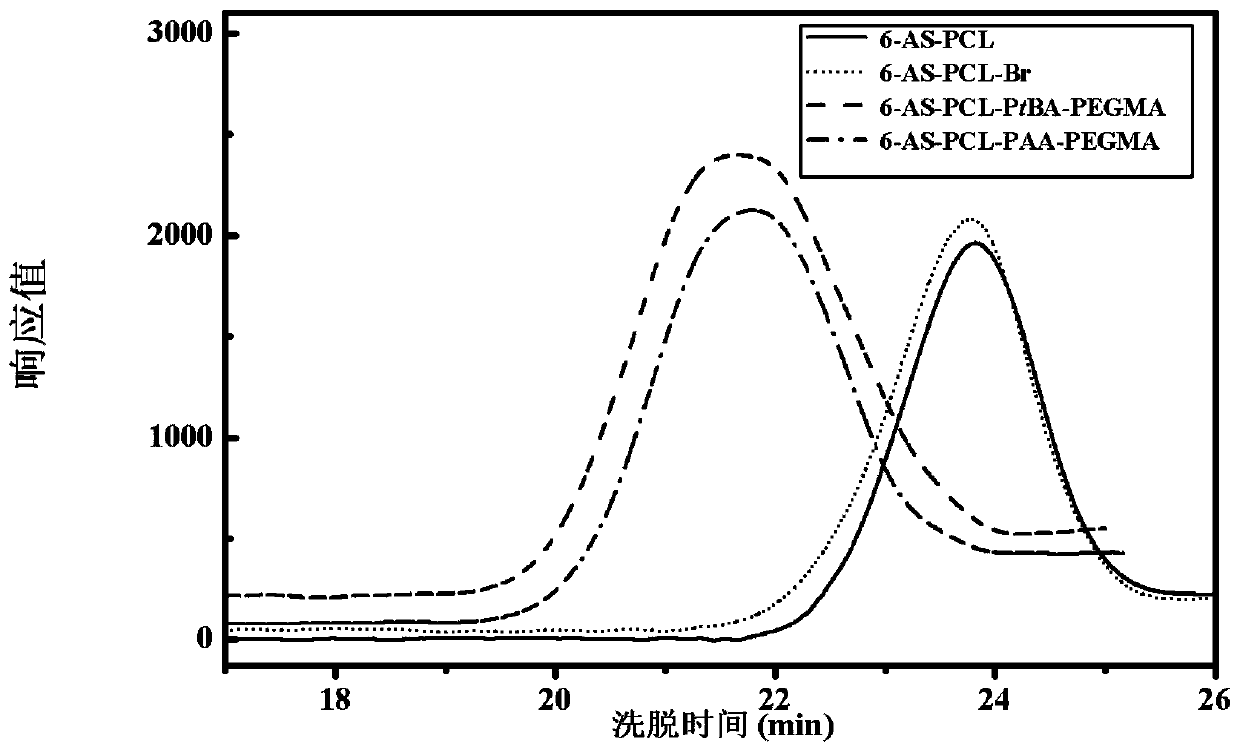

[0062] Example 1: Preparation of six-arm star-shaped amphiphilic polymer 6-AS-PCL-PAA-PPEGMA

[0063] (1) Preparation of macromolecular initiator 6-AS-PCL: get 100mL dry reaction bottle, cool after 10 minutes with alcohol lamp baking, stir bar, initiator dipentaerythritol (1.27g, 5mmol) are added in the reaction bottle, and use Sealed with a rubber stopper. After evacuating-argon for 3 times, add monomer ε-caprolactone (34.22g, 300mmol) under the protection of argon. After heating in an oil bath at 150°C for 20 minutes, add Sn(Oct) 2 (0.1wt%ofε-CL, 0.03g), then stop heating after 24h of reaction, cool the eggplant-shaped bottle, add 30mL of anhydrous THF to dissolve the white sticky solid, in 300mL of cold methanol / water (1:1, v / v) After precipitation, filter to remove unreacted monomer and catalyst, and obtain a white powdery solid after vacuum drying (or the product is vacuum dried at 40°C and 35mb for 24h). The synthetic reaction formula is shown in formula (1). The mol...

Embodiment 2

[0079] Example 2: Preparation of six-armed star-shaped amphiphilic polymer 6-AS-PCL-PAA-PPEGMA

[0080] (1) Preparation of macromolecular initiator 6-AS-PCL: get 100mL dry reaction bottle, cool after 10 minutes with alcohol lamp baking, stir bar, initiator dipentaerythritol (1.27g, 5mmol) are added in the reaction bottle, and use Sealed with a rubber stopper. After evacuating-argon for 3 times, add monomer ε-caprolactone (17.11g, 150mmol) under the protection of argon, and perform three freezing-pumping-heating cycles with liquid nitrogen, then place After heating in an oil bath at 130°C for 20 minutes, add Sn(Oct) 2 (0.1wt%ofε-CL, 0.03g), then stop heating after 24h of reaction, cool the eggplant-shaped bottle, add 30mL of anhydrous THF to dissolve the white sticky solid, in 300mL of cold methanol / water (1:1, v / v) After precipitation, filter to remove unreacted monomer and catalyst, and obtain a white powdery solid after vacuum drying (or the product is vacuum dried at 40°C a...

Embodiment 3

[0084] Example 3: Preparation of six-armed star-shaped amphiphilic polymer 6-AS-PCL-PAA-PPEGMA

[0085] (1) Preparation of macromolecular initiator 6-AS-PCL: get 100mL dry reaction bottle, cool after 10 minutes with alcohol lamp baking, stir bar, initiator dipentaerythritol (1.27g, 5mmol) are added in the reaction bottle, and use Sealed with a rubber stopper. After evacuating-argon for 3 times, add the monomer ε-caprolactone (51.33g, 450mmol) under the protection of argon. After heating in an oil bath at 130°C for 20 minutes, add Sn(Oct)2 (0.1wt% ofε-CL, 0.03g), then stop heating after 48 hours of reaction, cool the eggplant-shaped bottle, and add 30mL of anhydrous THF to dissolve the white Viscous solid, filtered after precipitation in 300 mL of cold methanol / water (1:1, v / v) to remove unreacted monomer and catalyst, gave a white powdery solid after vacuum drying (or product at 40 °C, 35 mb vacuum Dry 24h). The synthetic reaction formula is shown in formula (1).

[0086] ...

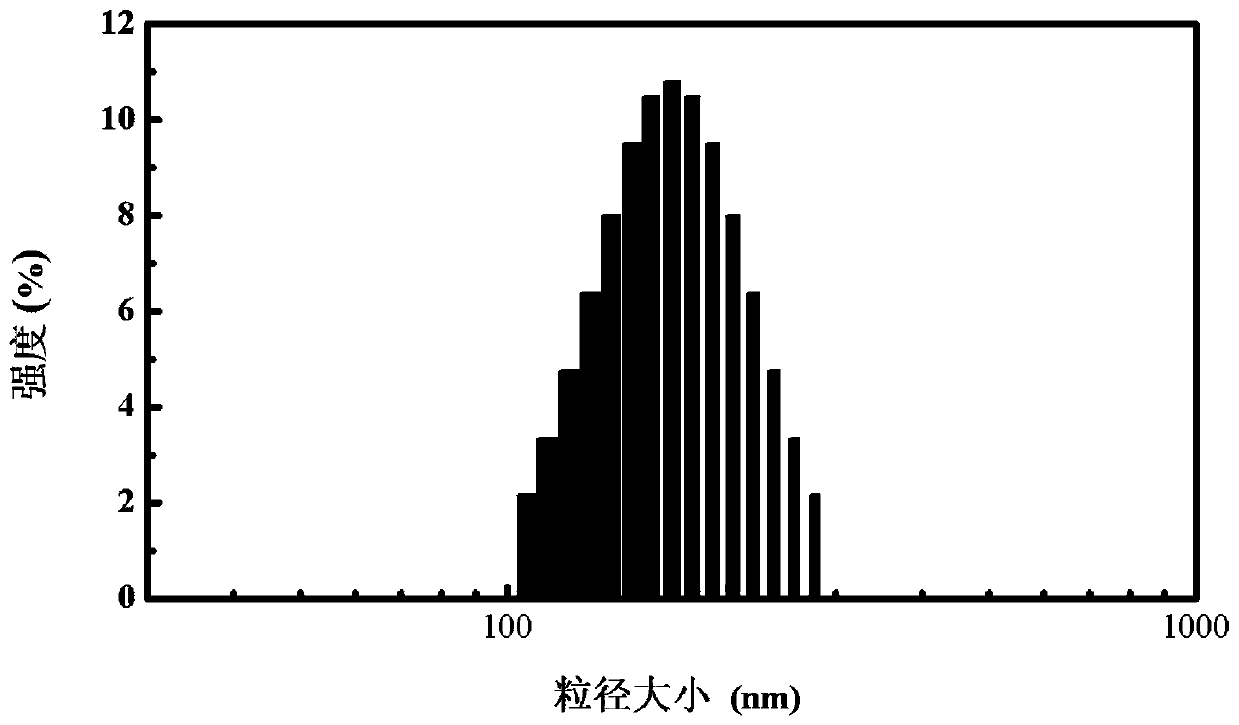

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com