Negative ion ceramic tile and preparation method thereof

A technology of ceramic bricks and negative ions, applied in the field of negative ion ceramic bricks and their preparation, can solve the problems of large consumption of negative ion materials and high cost, and achieve the effects of long-term release of negative ions, cost reduction and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

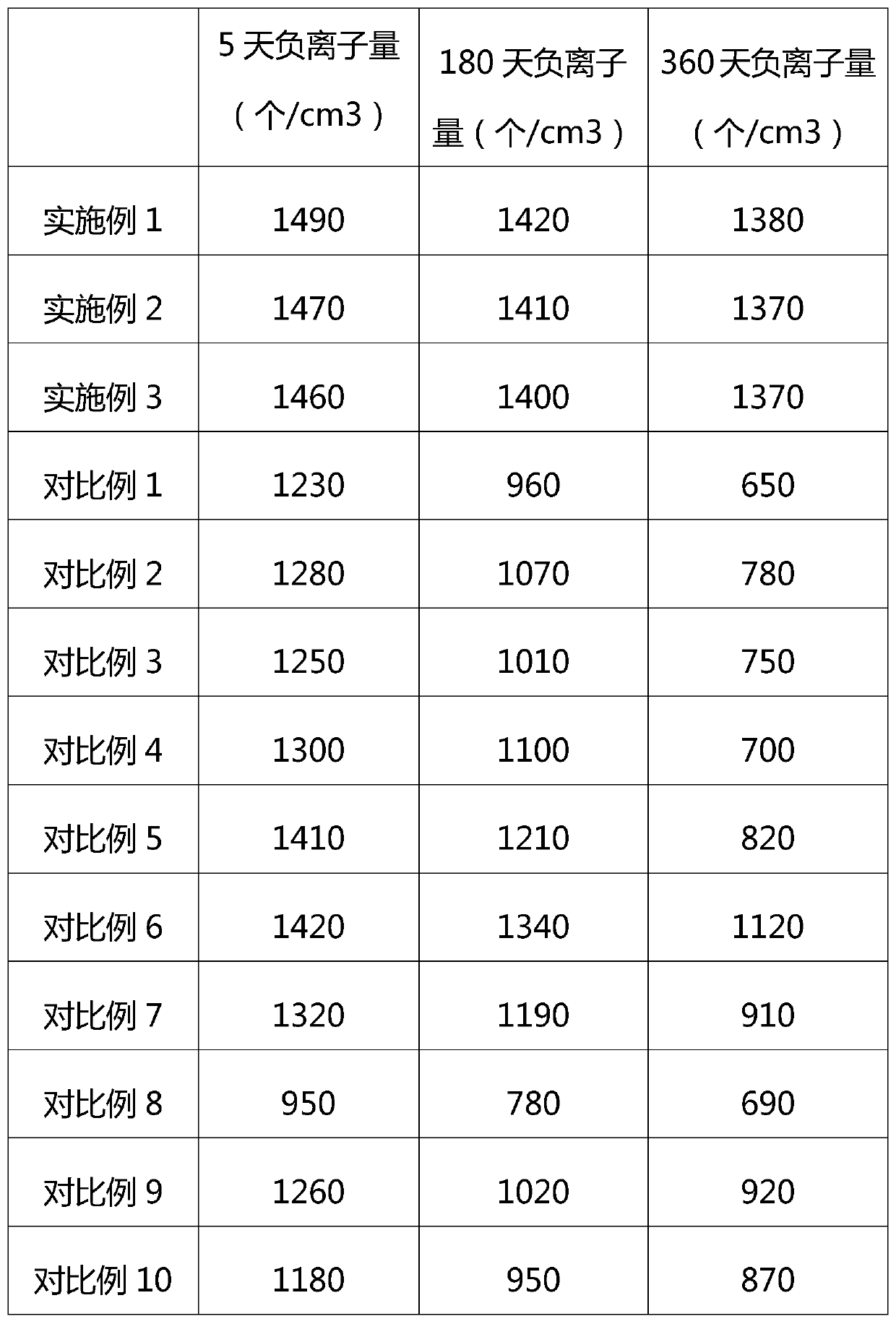

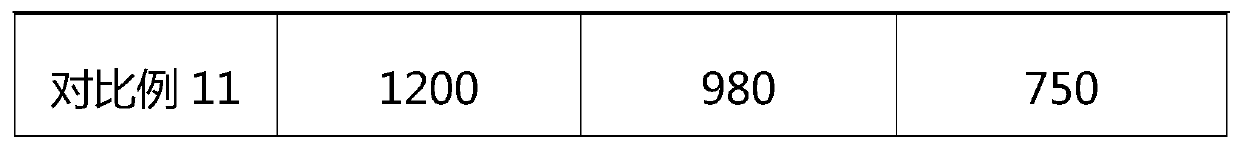

Examples

Embodiment 1

[0021] A kind of negative ion ceramic tile, described it comprises body layer and glaze material layer; The preparation raw material of described glaze material layer comprises by weight: 4 parts of negative ion powder, 40 parts of attapulgite, 30 parts of porous diatomite, 11.5 parts of glass-ceramic, 25 parts of titanium dioxide, 7.5 parts of zinc oxide, 2.5 parts of modified phenolic resin and 3 parts of titanate coupling agent; wherein, the preparation method of the negative ion powder is: tourmaline powder, nano cuprous oxide , tin dichloride, nano-zinc oxide, after mixing, heat at 200°C for 1 hour, and heat at 350°C for 1 hour to obtain the primary sintered product, then add pentahydroxide iron, LiTFSi, silicone, after mixing evenly, 500°C The modified phenolic resin can be modified by adding 0.5% of 1,3-dimethylimidazolium phosphate dimethyl salt after sintering in a nitrogen atmosphere. The ratio of tourmaline powder, nano-cuprous oxide, tin dichloride, and nano-zinc o...

Embodiment 2

[0030] A kind of negative ion ceramic tile, described it comprises green body layer and glaze material layer; The preparation raw material of described glaze material layer comprises by weight: 3 parts of negative ion powder, 50 parts of attapulgite, 20 parts of porous diatomite, 15 parts of glass-ceramic, 20 parts of titanium dioxide, 10 parts of zinc oxide, 2 parts of modified phenolic resin and 5 parts of titanate coupling agent; wherein, the preparation method of the negative ion powder is: tourmaline powder, nano cuprous oxide , tin dichloride, nano-zinc oxide, after mixing, heat at 200°C for 1 hour, and heat at 350°C for 1 hour to obtain the primary sintered product, then add pentahydroxide iron, LiTFSi, silicone, after mixing evenly, 500°C The modified phenolic resin can be modified by adding 0.5% of 1,3-dimethylimidazolium phosphate dimethyl salt after sintering in a nitrogen atmosphere. The ratio of tourmaline powder, nano-cuprous oxide, tin dichloride, and nano-zinc ...

Embodiment 3

[0039] A kind of negative ion ceramic tile, described it comprises green body layer and glaze material layer; The preparation raw material of described glaze material layer comprises by weight: 5 parts of negative ion powder, 30 parts of attapulgite, 40 parts of porous diatomite, 8 parts of glass-ceramic, 30 parts of titanium dioxide, 5 parts of zinc oxide, 3 parts of modified phenolic resin and 1 part of titanate coupling agent; wherein, the preparation method of the negative ion powder is: tourmaline powder, nano cuprous oxide , tin dichloride, nano-zinc oxide, after mixing, heat at 200°C for 1 hour, and heat at 350°C for 1 hour to obtain the primary sintered product, then add pentahydroxide iron, LiTFSi, silicone, after mixing evenly, 500°C The modified phenolic resin can be modified by adding 0.5% of 1,3-dimethylimidazolium phosphate dimethyl salt after sintering in a nitrogen atmosphere. The ratio of tourmaline powder, nano-cuprous oxide, tin dichloride, and nano-zinc oxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com