Preparation method of microwave dielectric sintered powder material, microwave dielectric ceramic and application thereof

A microwave dielectric ceramic and microwave dielectric technology, which is applied to waveguide devices, electrical components, circuits, etc., achieves the effects of excellent microwave performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

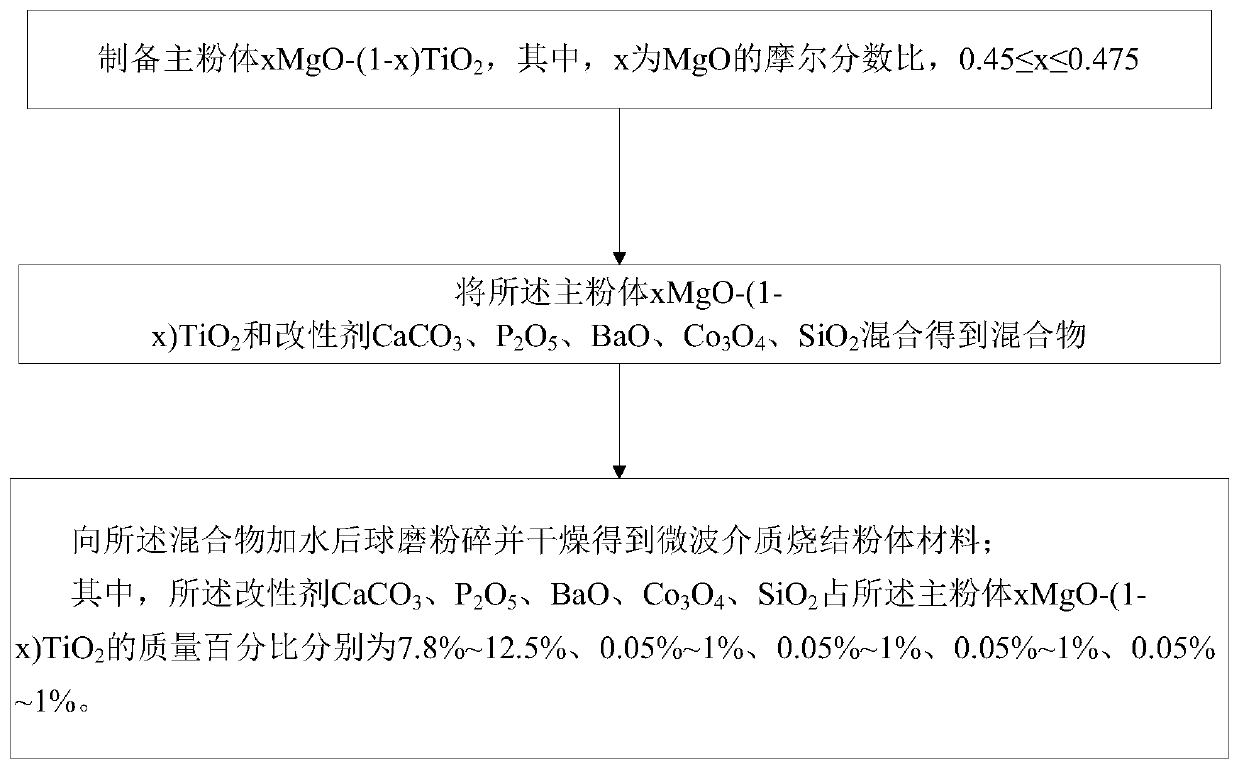

[0027] Such as figure 1 As shown, this embodiment provides a method for preparing a microwave dielectric sintering powder material, which includes the following steps:

[0028] S1: Preparation of main powder xMgO-(1-x)TiO 2 , wherein, x is the mole fraction ratio of MgO, wherein x=0.45;

[0029] S2: The main powder 0.45MgO-0.55TiO 2 and modifier CaCO 3 ,P 2 o 5 , BaO, Co 3 o 4 , SiO 2 mix to obtain a mixture;

[0030] S3: adding water to the mixture, ball milling, and drying to obtain.

[0031] Among them, modifier CaCO 3 ,P 2 o 5 , BaO, Co 3 o 4 , SiO 2 Accounting for the main powder 0.45MgO-0.55TiO 2 The mass percentages were 12.5% CaCO 3 , 0.05%P 2 o 5 , 0.05% BaO, 0.05% Co 3 o 4 , 1% SiO 2 . Among them, MgO and TiO 2 The particle size is 1 μm, CaCO3 , BaO and SiO 2 The particle size is 200nm.

[0032] In a specific embodiment, spray drying is used.

[0033] Among them, the main powder is 0.45MgO-0.55TiO 2 Prepared by the following method: MgO ...

Embodiment 2

[0035] This embodiment provides a method for preparing a microwave dielectric sintering powder material, which includes the following steps:

[0036] S1: Preparation of main powder xMgO-(1-x)TiO 2 , wherein, x is the mole fraction ratio of MgO, wherein x=0.46;

[0037] S2: the main powder 0.46MgO-0.54TiO 2 and modifier CaCO 3 ,P 2 o 5 , BaO, Co 3 o 4 , SiO 2 mix to obtain a mixture;

[0038] S3: adding water to the mixture, ball milling, and drying to obtain.

[0039] Among them, the modifier accounts for 0.46MgO-0.54TiO in the main powder 2 The mass percentages were 11.6% CaCO 3 , 0.1%P 2 o 5 , 0.05% BaO, 0.05% Co 3 o 4 , 0.1% SiO 2 . Among them, MgO and TiO 2 The particle size is 2 μm, CaCO 3 , BaO and SiO 2 The particle size is 150nm.

[0040] Wherein, the main powder is 0.46MgO-0.54TiO 2 Prepared by the following method: MgO and TiO 2 Mixed at a molar ratio of 0.46:0.54, added water, ball milled, dried, pre-calcined at 1150°C for 2 hours, and obtained...

Embodiment 3

[0042] This embodiment provides a method for preparing a microwave dielectric sintering powder material, which includes the following steps:

[0043] S1: Preparation of main powder xMgO-(1-x)TiO 2 , wherein, x is the mole fraction ratio of MgO, wherein x=0.47;

[0044] S2: The main powder 0.47MgO-0.53TiO 2 and modifier CaCO 3 ,P 2 o 5 , BaO, Co 3 o 4 , SiO 2 mix to obtain a mixture;

[0045] S3: adding water to the mixture, ball milling, and drying to obtain.

[0046] Among them, the modifier accounts for 0.47MgO-0.53TiO in the main powder 2 The mass percentages were 9.1% CaCO 3 , 0.1%P 2 o 5 , 1% BaO, 1% Co 3 o 4 , 0.05% SiO 2 . Among them, MgO and TiO 2 The particle size is 20μm, CaCO 3 , BaO and SiO 2 The particle size is 100nm.

[0047] Wherein, the main powder is 0.47MgO-0.53TiO 2 Prepared by the following method: MgO and TiO 2 Mixed at a molar ratio of 0.47:0.53, added water, ball milled, dried, pre-calcined at 1150°C for 2 hours, and obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com