Flake like ceramic wave absorbing material and preparation method thereof

A wave-absorbing material and a sheet-like technology are applied in the field of sheet-like ceramic wave-absorbing materials and their preparation, which can solve the problems of difficulty in achieving impedance matching, inability to provide high magnetic loss, and low saturation magnetization, and achieve good microwave impedance matching characteristics. , the effect of good microwave absorption characteristics, excellent electromagnetic loss characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

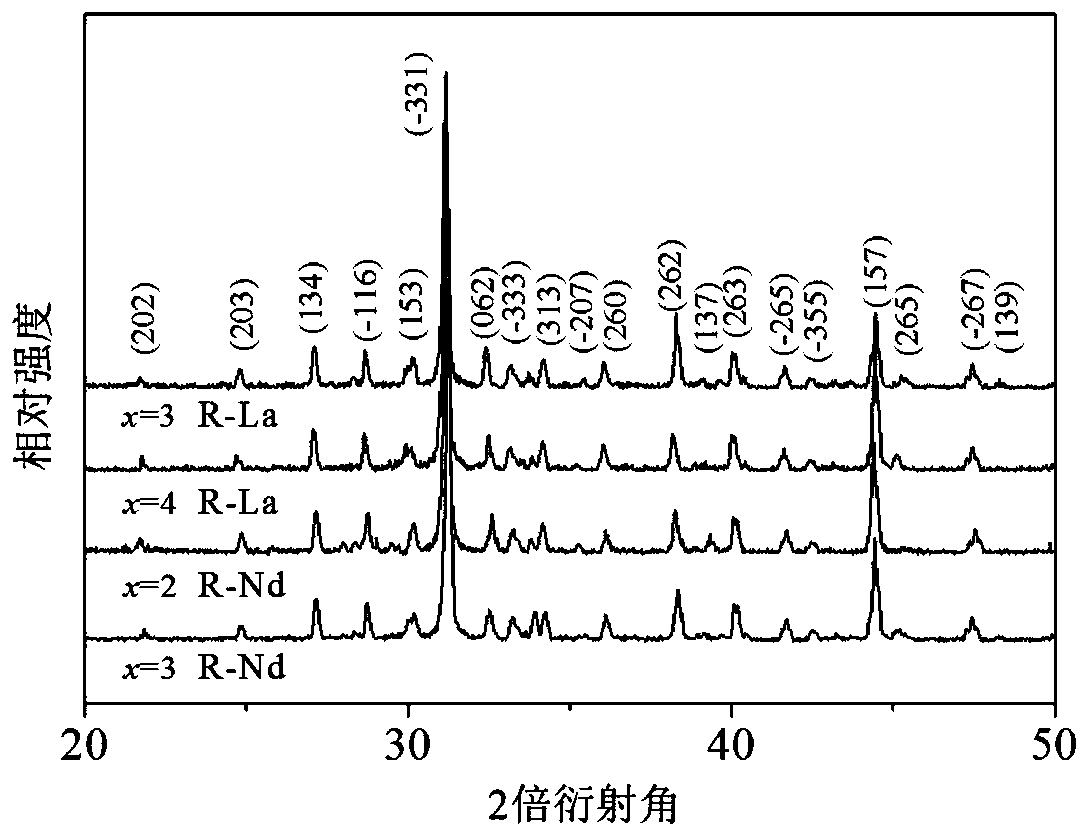

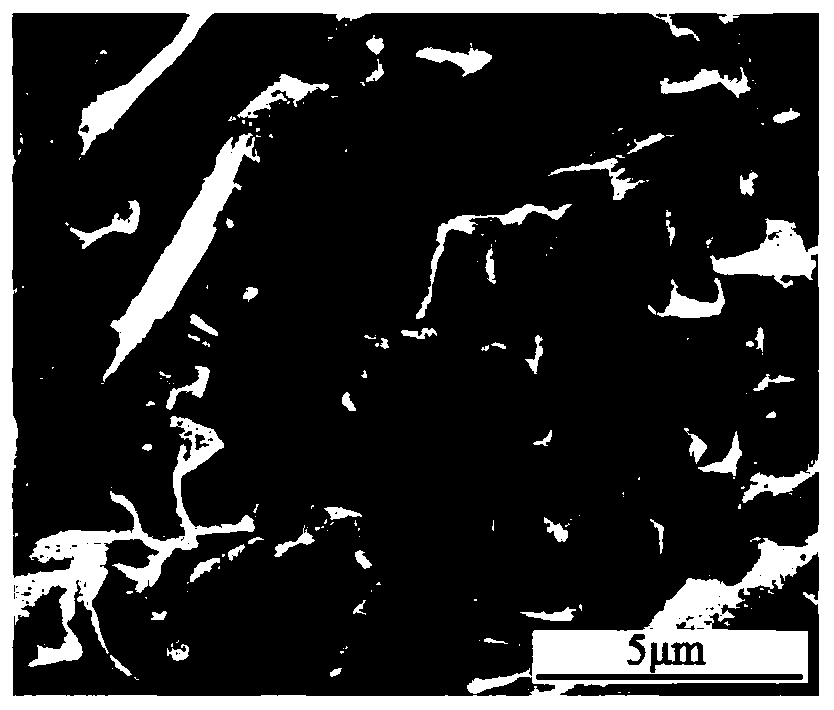

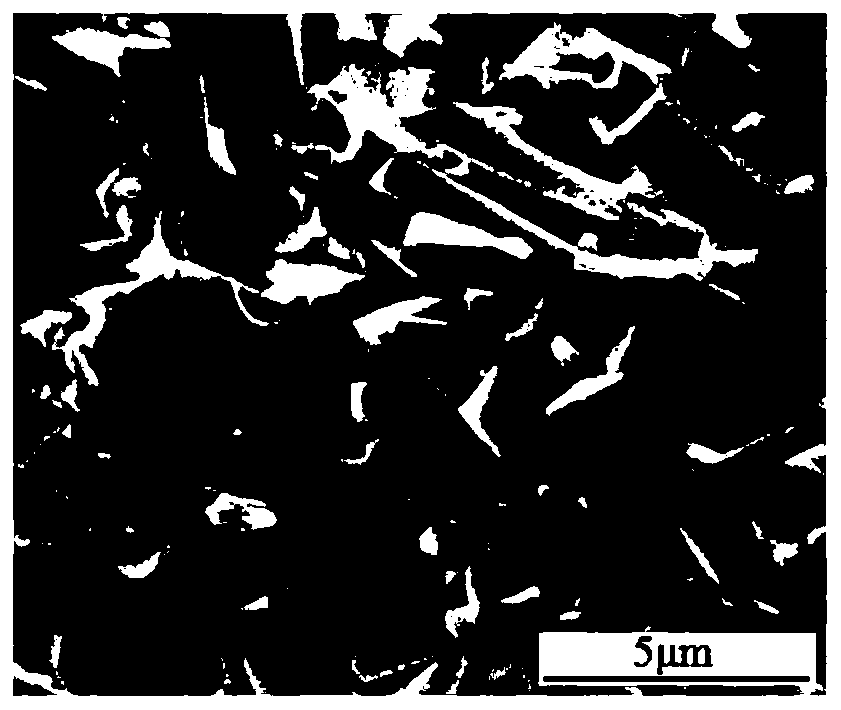

[0038] In this embodiment, the sheet-shaped ceramic wave-absorbing material Ba 12-x R x Fe 28 Ti 15 o 84 ( x =3, R is La) is a kind of layered oxide with monoclinic crystal structure, the space group is C 2 / m ; The monoclinic crystal structure is randomly arranged flaky grains with a diameter of 2 to 7 µ m, thickness 1~2 µ m;

[0039] A kind of sheet ceramic absorbing material Ba 12-x R x Fe 28 Ti 15 o 84 ( x =3, R is the preparation method of La), comprises the following steps:

[0040] (1) Preparation of sol: Weigh 11.76g of barium nitrate (98.5% in purity) and 6.50g of lanthanum nitrate hexahydrate (99% in purity) according to the stoichiometric ratio of Ba:La:Fe:Ti: 9:3:28:15 ), 48.48g ferric nitrate nonahydrate (purity 98.5%), 25.53g n-butyl titanate (purity 98%), 700mL deionized water, 17.68g ethylenediaminetetraacetic acid (purity 98%) and 46.49g Citric acid (purity: 98%) was stirred to obtain a uniform mixed solution; ammonia water was added to the mix...

Embodiment 2

[0050] The chemical formula of the sheet-shaped ceramic wave-absorbing material of this embodiment is Ba 12-x R x Fe 28 Ti 15 o 84 ( x =4, R is La), its preparation method comprises the following steps:

[0051] (1) Preparation of sol: Weigh 10.45g of barium nitrate (98.5% in purity) and 8.66g of lanthanum nitrate hexahydrate (99% in purity) according to the stoichiometric ratio of Ba:La:Fe:Ti: 8:4:28:15 ), 48.48g ferric nitrate nonahydrate (purity 98.5%), 25.53g n-butyl titanate (purity 98%), add 700mL deionized water, 66.05g citric acid (purity 98%), and stir to obtain a uniform mixture solution; then add ammonia water to the mixed solution, adjust the pH value to 7, place in a water bath at a constant temperature of 90°C, heat for 5 hours, and stir at 400rpm / min for 5 hours to obtain a stable and uniform precursor sol;

[0052] (2) Preparation of primary powder: Place the sol obtained in step (1) in a drying oven at 120°C and dry for 5 hours to obtain a fluffy black x...

Embodiment 3

[0058] In this embodiment, the sheet-shaped ceramic wave-absorbing material Ba 12-x R x Fe 28 Ti 15 o 84 ( x =2, R is Nd) is a kind of layered oxide with monoclinic crystal structure, the space group is C 2 / m ; The monoclinic crystal structure is randomly arranged plate grains with a diameter of 3-7 µ m, thickness 1~2 µ m;

[0059] A kind of sheet ceramic absorbing material Ba 12-x R x Fe 28 Ti 15 o 84 ( x =2, R is the preparation method of Nd), comprising the following steps:

[0060](1) Preparation of sol: Weigh 13.07g barium nitrate (purity 98.5%) and 4.38g neodymium nitrate hexahydrate (purity 99%) according to Ba:Nd:Fe:Ti stoichiometric ratio 10:2:28:15 , 48.48g ferric nitrate nonahydrate (98.5% purity), 25.53g n-butyl titanate (98% purity) were added to 700mL deionized water, 17.93g ethylenediaminetetraacetic acid (98% purity) and 58.88g lemon Acid (purity: 98%), stirred to obtain a uniform mixed solution; then added ammonia water to the mixed solution, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com