Arc-shaped panel polishing device for machining of electromechanical equipment

A technology of curved panels and electromechanical equipment, which is applied in the direction of grinding/polishing safety devices, surface polishing machine tools, grinding drive devices, etc., can solve the problems of poor polishing effect and easy movement of curved panels on the device, and achieve Better use effect, better polishing effect, fixed and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

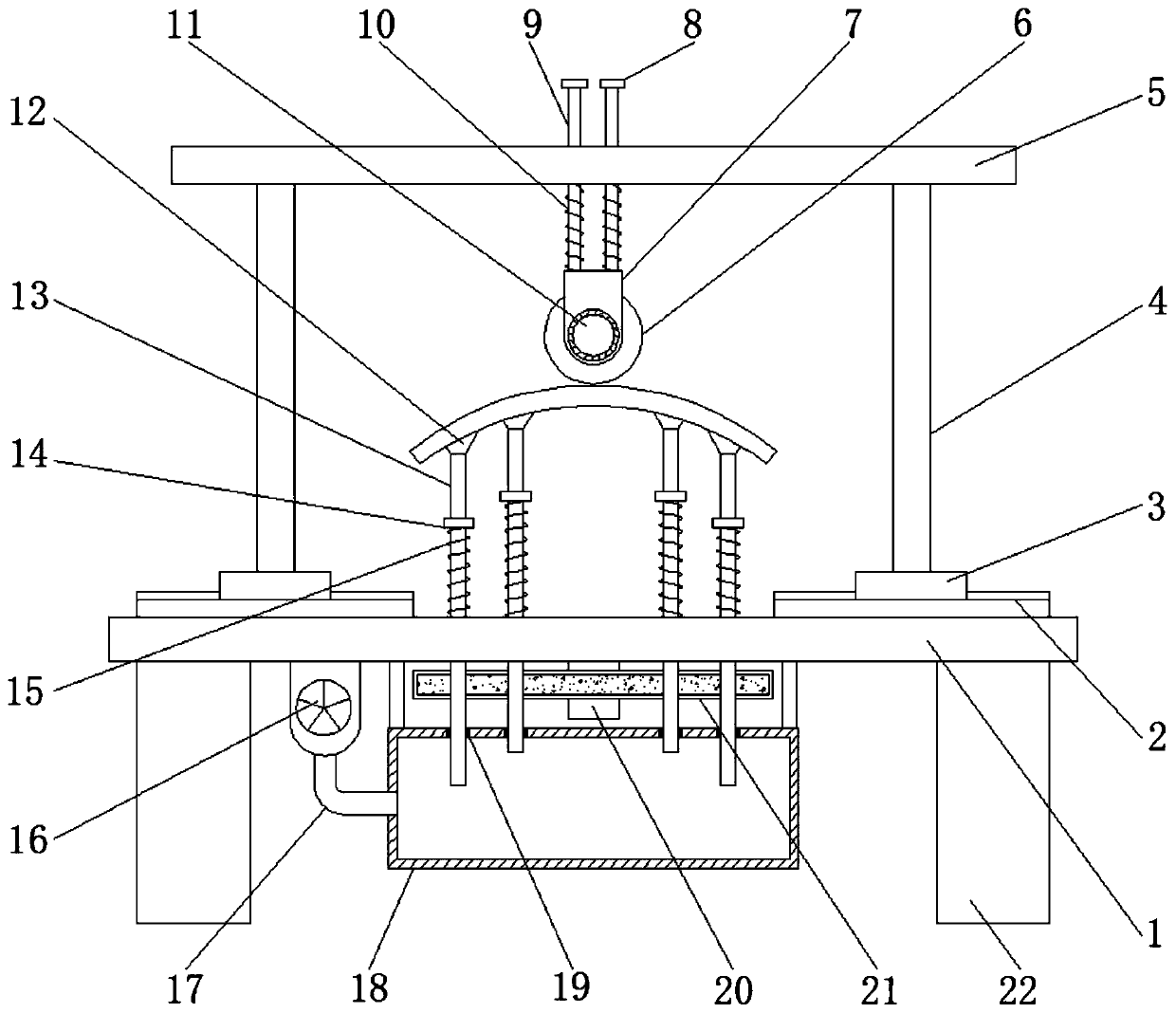

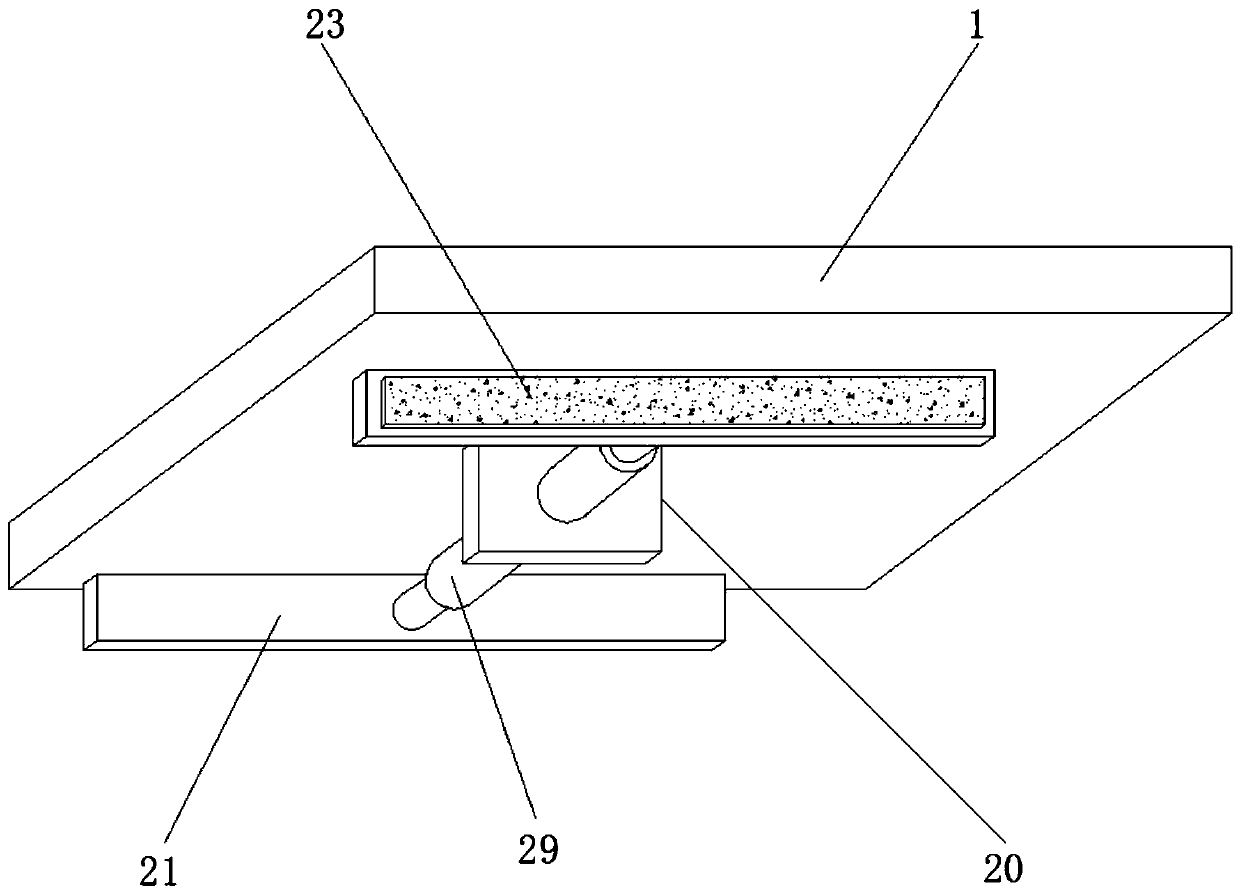

[0026] Reference Figure 1-2 , An arc panel polishing device for electromechanical equipment processing, comprising a workbench 1. The four corners of the outer wall of the top of the workbench 1 are all connected with an electric slide rail 2 by bolts, and the inner wall of the electric slide rail 2 is slidingly connected with a slider 3. The top outer wall of the slider 3 is welded with a column 4, and the top outer wall of the column 4 is welded with a top plate 5, the top outer wall of the top plate 5 is provided with a sliding hole, and the inner wall of the sliding hole is slidably connected with a sliding rod 9 The bottom outer wall is welded with a fixed frame 7, and one outer wall of the fixed frame 7 is connected with a motor 11 through bolts. One end of the output shaft of the motor 11 is provided with a polishing roller 6, and the outer wall of the sliding rod 9 is sleeved with a first spring 10, and the The top outer wall of the rod 9 is welded with a stopper 8. Th...

Embodiment 2

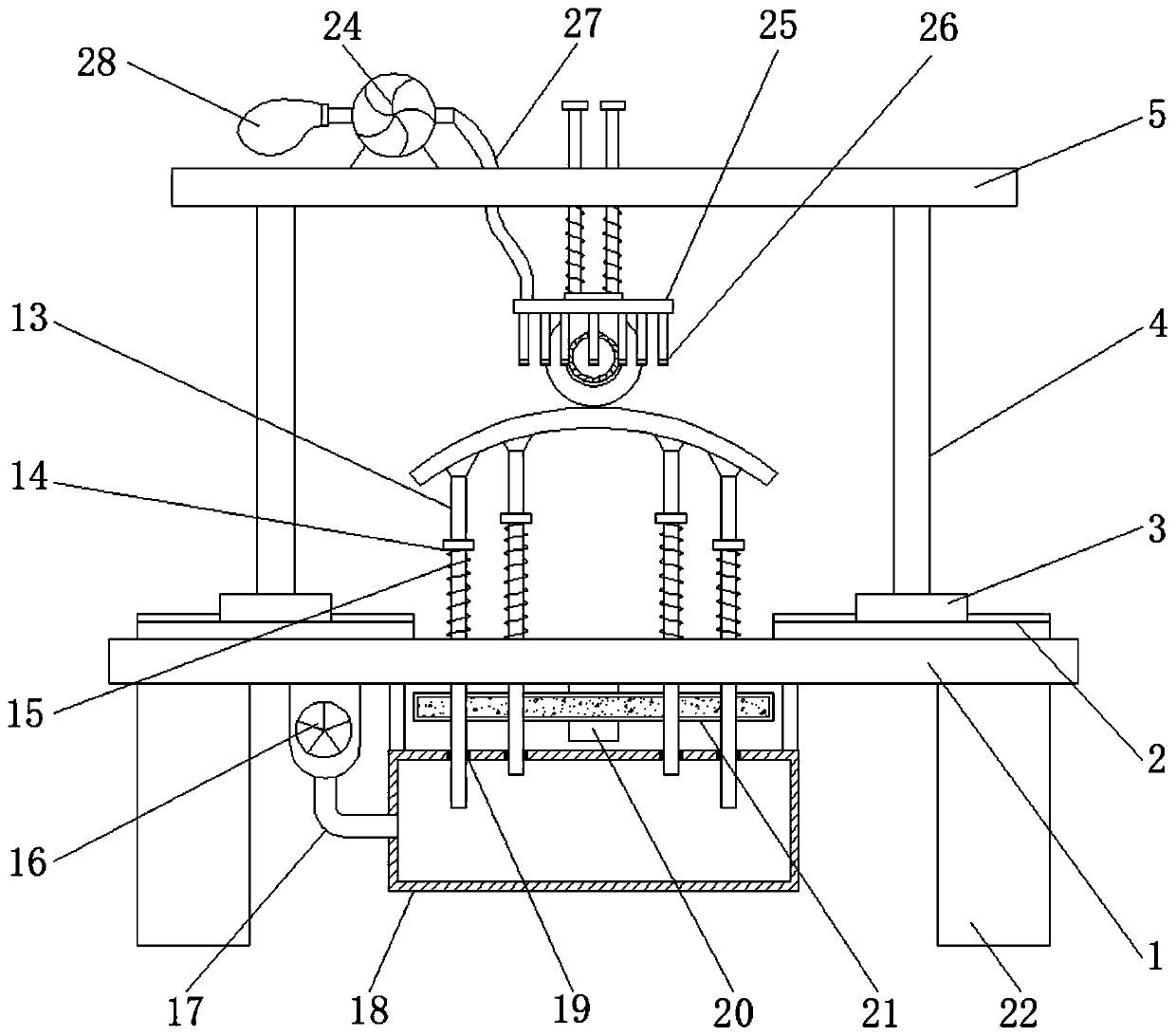

[0030] Reference image 3 , An arc-shaped panel polishing device for machining electromechanical equipment. Compared with the first embodiment, this embodiment also includes a ring tube 25 welded to the outer wall of the fixed frame 7, and the bottom outer wall of the ring tube 25 is welded at equal distances to form an annular distribution The dust suction pipe 26, the top outer wall of the top plate 5 is connected with an exhaust fan 24 by bolts, and the air outlet end of the exhaust fan 24 is provided with a hose 27, one end of the hose 27 is connected to the ring tube 25, and the inlet of the exhaust fan 24 The air end is provided with an exhaust pipe, and the outer wall of the exhaust pipe is threadedly connected with a threaded ring, and the outer wall of the threaded ring is bonded with a dust collecting bag 28.

[0031] Working principle: When in use, the exhaust fan 24 can be driven to work, and the dust generated by polishing is absorbed through the dust suction tube 26 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com