Method for predicting fatigue life by utilizing weak magnetic signal of ferromagnetic material

A technology for ferromagnetic materials and fatigue life, which is applied to the analysis of materials, the application of repeated force/pulsation force to test the strength of materials, and measuring devices, etc. It can solve the problems of not being able to warn the initial damage site and not reflecting the internal mechanism of material damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

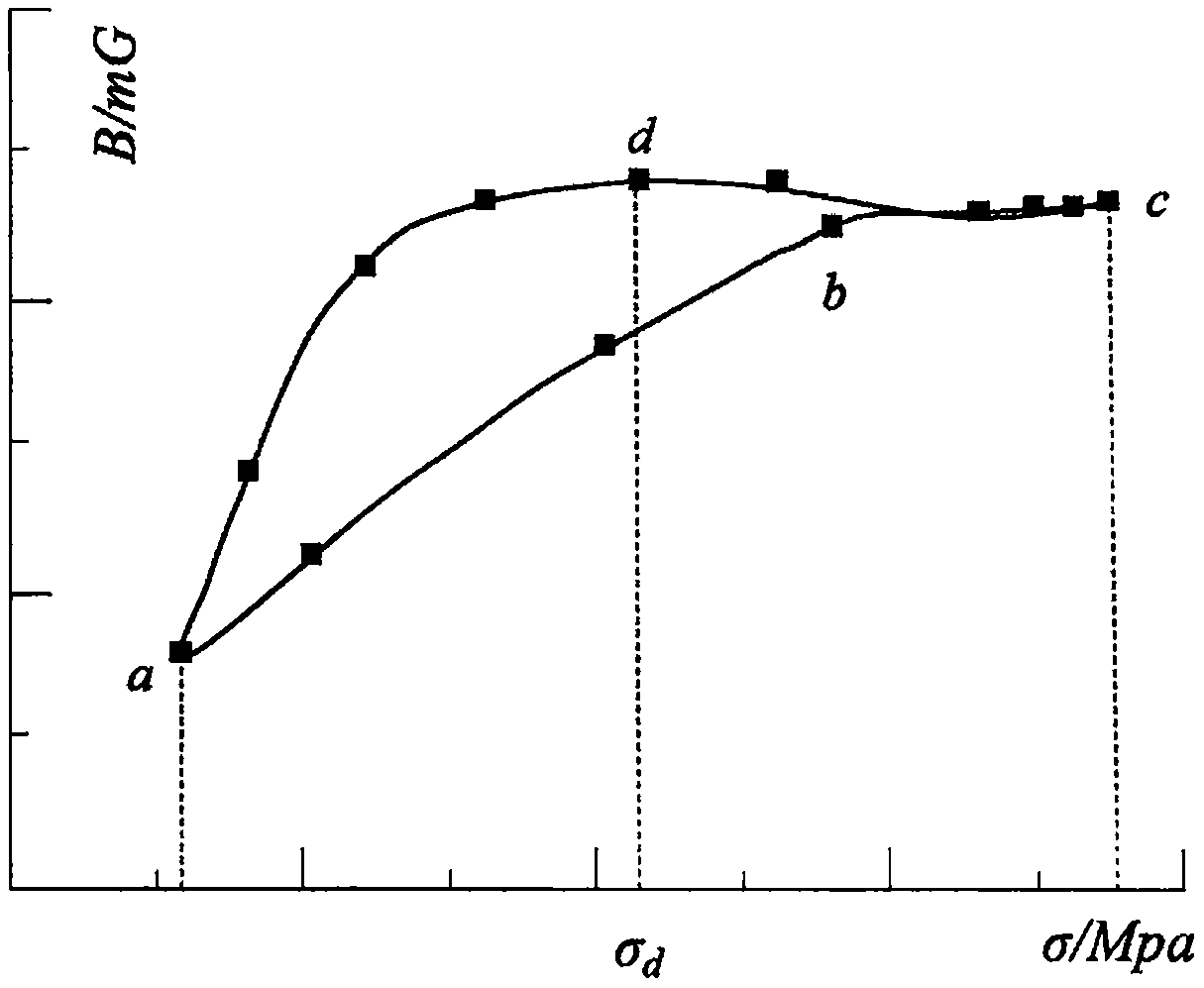

[0025] Such as figure 1 , figure 2 As shown, the present invention uses the weak magnetic signal of ferromagnetic material to predict the fatigue life method, which includes the following steps.

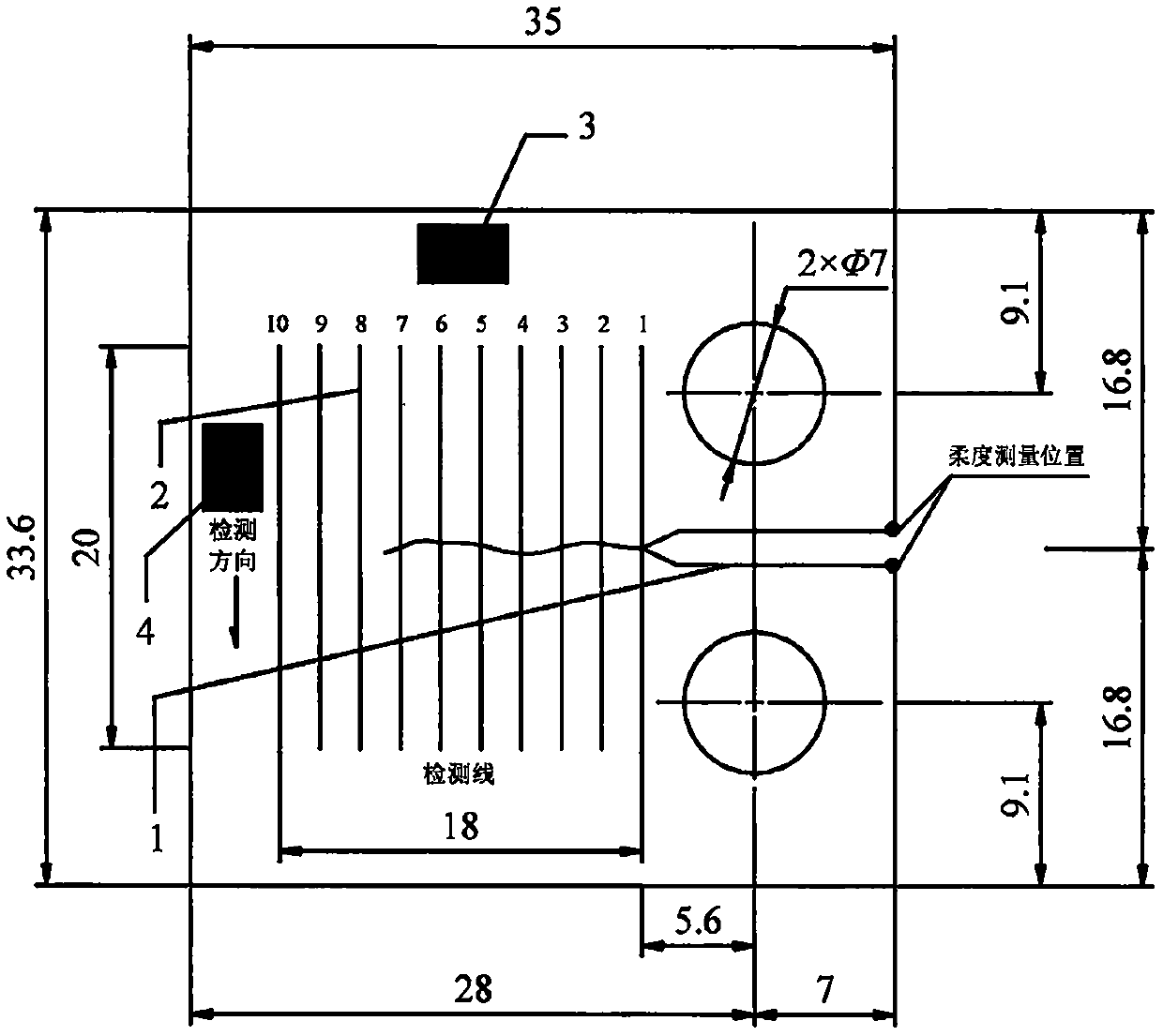

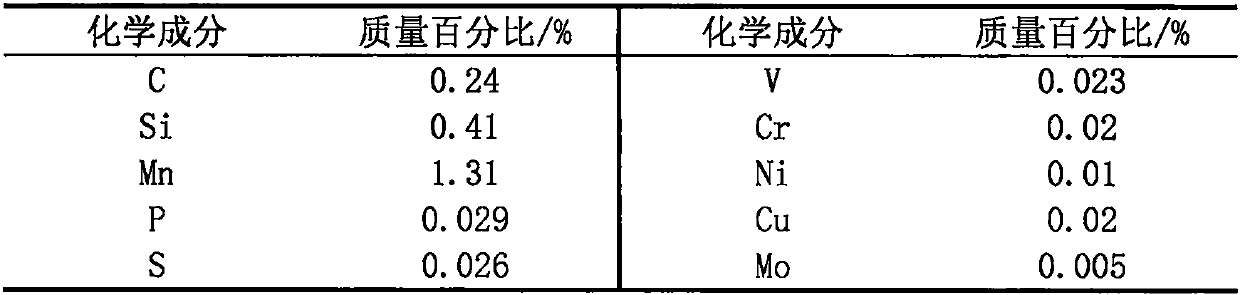

[0026] 1. Taking the standard compact tensile (CT) sample made of steel as an example, a radial CT sample with a straight-through V-shaped notch is prepared by wire cutting technology, so that the size and surface flatness of the sample meet the specification requirements , and measure the actual size as the calculation basis, carry out final heat treatment on the standard sample according to the specification, so that the surface of the standard sample can obtain a pure initial magnetic state.

[0027] 2. Fix the sample on the fatigue testing machine, and install the weak magnetic signal test device, and mainly include the following steps.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com