A three-dimensional in-situ stress determination method based on borehole wall displacement measurement

A technology of displacement measurement and determination method, applied in the direction of measuring force component, soil material testing, earthwork drilling, etc., can solve problems such as failure of electronic components, difficulty in pasting strain roses, inability to obtain stress parameters correctly, etc. The effect of small, shortened test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for determining three-dimensional ground stress based on borehole wall displacement measurement, the steps of which are:

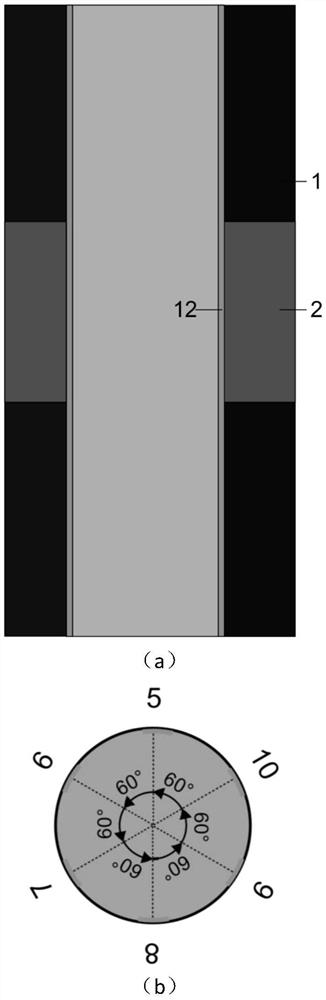

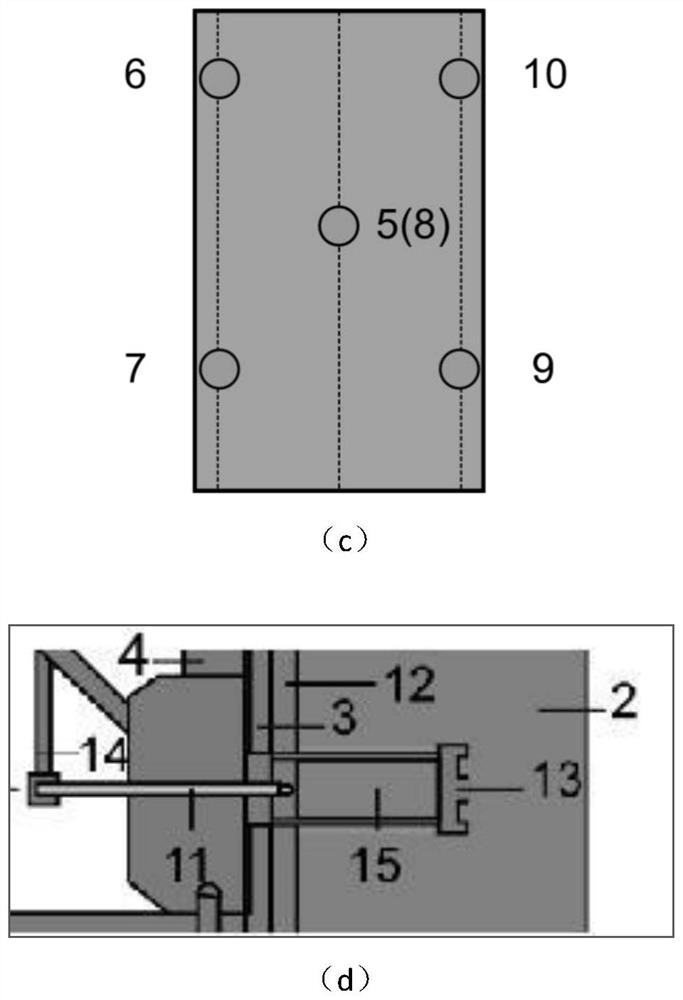

[0030] A. If figure 1 As shown in (a), the logging analysis is carried out in the shale gas exploration hole 1, and the diameter of the shale gas exploration hole 1 can be selected as about. Combined with the results of well logging analysis, the test hole section 2 is selected for in-situ stress testing, and the side wall coring device 3 is lowered to 2100 or 2300 or 2600 or 2800 or 3000 meters through the drill pipe 4.

[0031] B. Arrange six first measurement points 5, second measurement points 6, third test points 7, fourth test points 8, fifth test points 9, and sixth test points 10 in the proposed test hole section 2, using plum blossoms Shaped layout, the angle between different test points between the drilling axes is 55° or 58° or 61° or 63° or 60°, and the axial distance is about 90 mm;

[0032] C. Taking the testing process o...

Embodiment 2

[0037] A method for determining three-dimensional ground stress based on borehole wall displacement measurement, the steps of which are:

[0038] A. If figure 1 As shown in (a), the logging analysis is carried out in the shale gas exploration hole 1, and the diameter of the shale gas exploration hole 1 can be selected as mm or so. Combined with the results of well logging analysis, the proposed test hole section 2 is selected for in-situ stress testing, and the side wall coring device 3 is lowered to the specified 2900 meters through the drill pipe 4.

[0039] B. Arrange six first measurement points 5, second measurement points 6, third test points 7, fourth test points 8, fifth test points 9, and sixth test points 10 in the proposed test hole section 2, using plum blossoms Shaped layout, the angle between different test points between the drilling axes is 55°, and the axial distance is about 120mm;

[0040] C. Taking the testing process of the first testing point 5 as an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com