A kind of method that acetone and hydrogen synthesize acetone condensate

A technology of acetone condensate and acetone, which is applied in the direction of chemical instruments and methods, preparation of organic compounds, carbon-based compounds, etc., can solve the problems of undisclosed application of high-gravity reactors, and achieve uniform distribution of reactants and mass transfer efficiency The effect of high and low investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

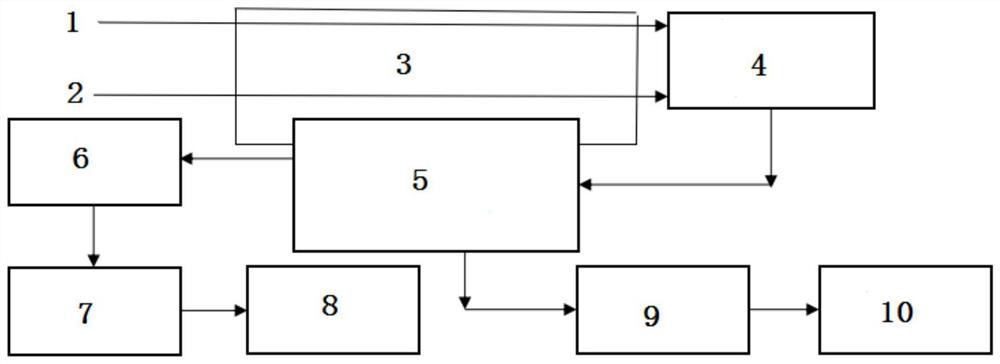

Method used

Image

Examples

Embodiment 1

[0038] Catalyst preparation method: Weigh Co (NO 3 ) 2 ·6H 2 O solid powder 42.91g, called Pr(NO 3 ) 3 ·6H 2 O Solid powder 11.02g, put into a beaker, add 50g of distilled water to the beaker, stir until Co (NO 3 ) 2 ·6H 2 O and Pr(NO 3 ) 3 ·6H 2 O All dissolved to give a salt solution; using the prepared salt solution impregnated with 100g strip alumina carrier, using one-step impregnation. After maceration, it is dried at 100 °C and calcined at 420 °C to obtain a catalyst. The main active components of the catalyst are cobalt with a mass content of 8%, the additive is praseodymium with a mass content of 4%, and the support is alumina.

[0039]Super gravity rotating bed setting: The above strip catalyst is placed into the mesh support inner part and fixed to the rotor of the supergravity rotating bed to form a catalyst bed that can be rotated. The inner diameter (radius) of the bed is 0.06m, the outer diameter (radius) of the bed is 0.26m, and the thickness of the bed is 0.2m.

...

Embodiment 2

[0053] As in Example 1, the only difference that exists is: the supergravity rotating bed is set to a bed inner diameter (radius) of 0.06m, the outer diameter of the bed (radius) is 0.36m, and the thickness of the bed is 0.3m.

[0054] When the speed of the supergravity rotary bed reactor is 200 rpm, 400 rpm, 600 rpm, 800 rpm, 1000 rpm, the residence time of the liquid phase component is calculated according to Equation 1, the liquid phase component flow rate L is 25 ml / h, and the residence time in the catalyst bed is 16.78s, 7.89s, 5.07s, 3.71s, 2.91s, respectively.

[0055] When the reaction is carried out for 100h, the liquid collected in the first and second tanks for nearly ten minutes is mixed together and analyzed. The main component content of the reaction product is listed in Table 3.

[0056] Table 3 The main components of the product after 100h reaction

[0057]

[0058]

[0059] When the reaction is carried out for 1000h, the liquid collected in the first tank and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com