Device for non-self-propelled ship to pass through tunnel for long distance

A long-distance, non-self-propelled technology, used in ship parts, ship construction, transportation and packaging, etc., can solve problems such as the efficiency of long-distance safe ships passing through tunnels, affecting the environment inside the tunnel, etc., to achieve convenient implementation, technical Reliable and enlarged water level amplitude effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

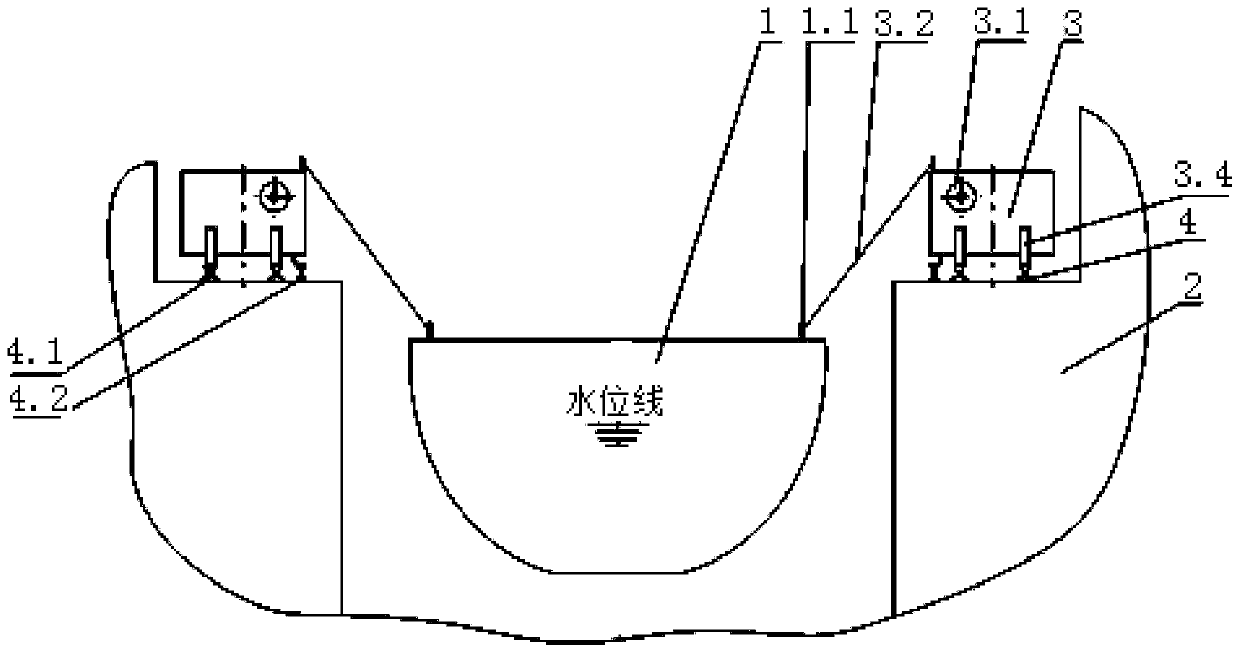

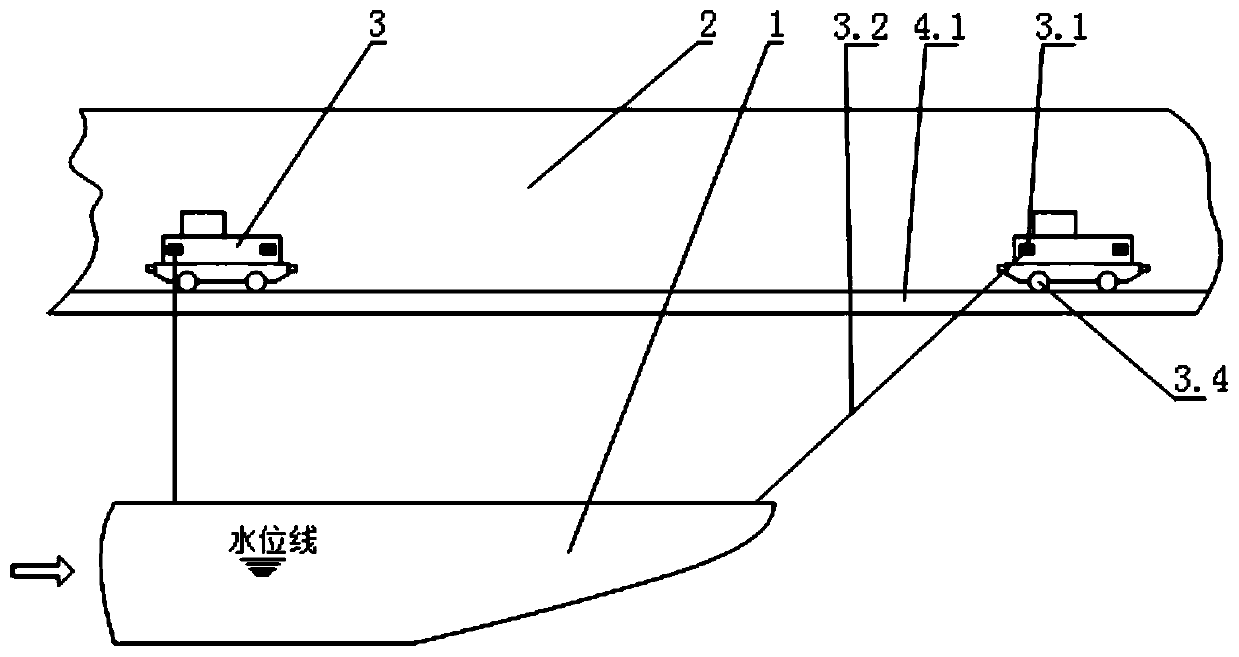

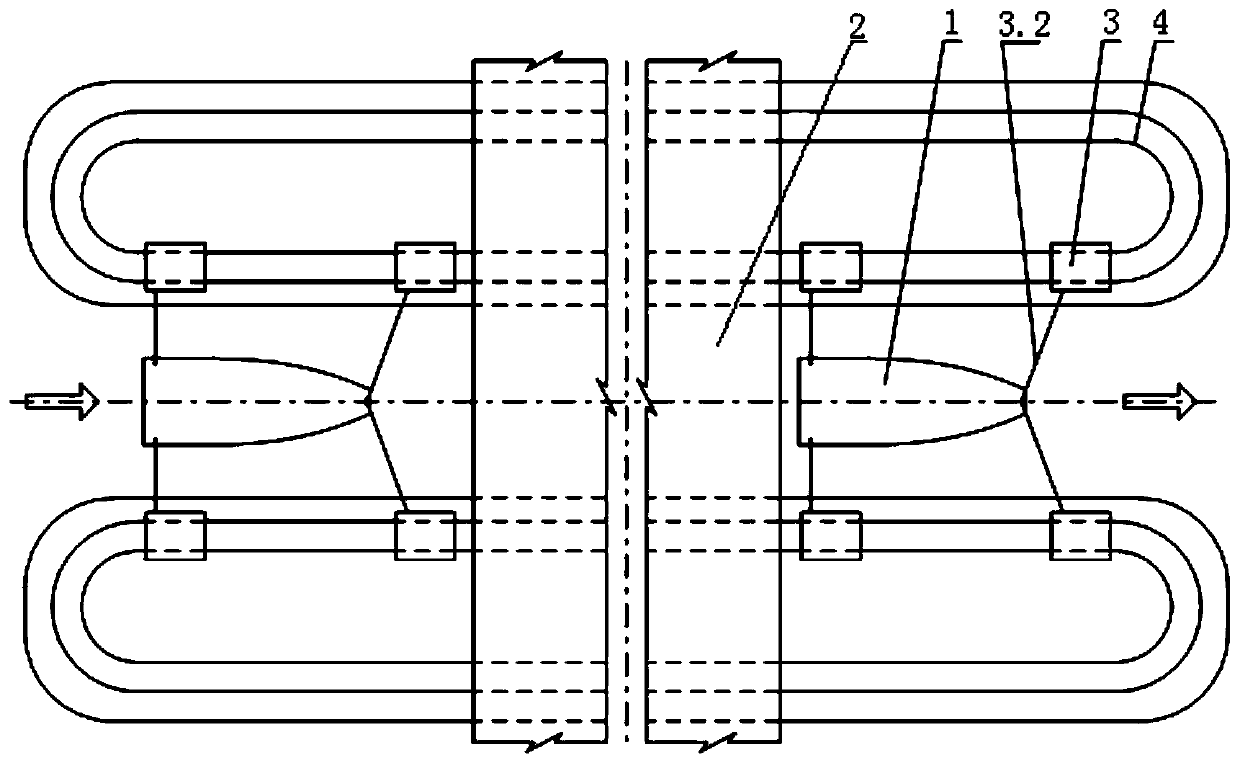

[0016] Such as Figure 1-3 As shown, a device for non-self-propelled ships passing through tunnels for long distances of the present invention includes a tunnel channel 2 for ships to be towed 1 to pass through, driving rails 4 arranged on the banks of both sides of the tunnel channel 2, and for traction The tractor 3 of the ship 1 is provided with a cable pile 1.1 on the ship 1 to be towed, and the tractor 3 is connected with the cable pile 1.1 through a traction cable 3.2. Movement, driving the ship 1 to be towed to move along the channel 2 of the tunnel.

[0017] In this embodiment, both sides of the bow and midship of the ship 1 to be towed are provided with bollards 1.1.

[0018] In this embodiment, the tractor 3 is driven by electricity, the tractor 3 is provided with an electric drive mechanism 3.4, the driving track 4 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com