Plasma circular seam welding hole shrinkage process method

A technology of plasma ring and process method, which is applied in the field of plasma ring seam welding hole closing technology, can solve the problems of incomplete penetration, burn-through, and poor forming of the small hole closing area of plasma ring seam, and achieve high quality requirements and good application effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for closing holes in plasma circular seam welding, comprising the steps of:

[0030] Step (1), the starting section of the circular seam:

[0031] (1.1) The protective gas is supplied for 5 seconds in advance.

[0032] (1.2) The welding current, ion gas, and weldment rotation start simultaneously, the welding current and ion gas rise, the weldment is perforated, the molten pool forms a small hole effect, and wire feeding starts;

[0033] (1.3) The welding current, ion gas, and wire feeding speed continue to increase until they reach the normal welding current of 100A, ion air flow of 0.5 scfh, and wire feeding speed of 800mm / min, and start normal welding and enter the welding section;

[0034] Step (2), circular seam welding section:

[0035] (2.1) The welding current in the normal welding section tends to decrease slowly and at a constant speed, and the total current drop from the beginning of welding to the end of the circular seam welding section is 5%;

...

Embodiment 2

[0043] A method for closing holes in plasma circular seam welding, comprising the steps of:

[0044] Step (1), the starting section of the circular seam:

[0045] (1.1) The protective gas is supplied for 10 seconds in advance.

[0046] (1.2) The welding current, ion gas, and weldment rotation start simultaneously, the welding current and ion gas rise, the weldment is perforated, the molten pool forms a small hole effect, and wire feeding starts;

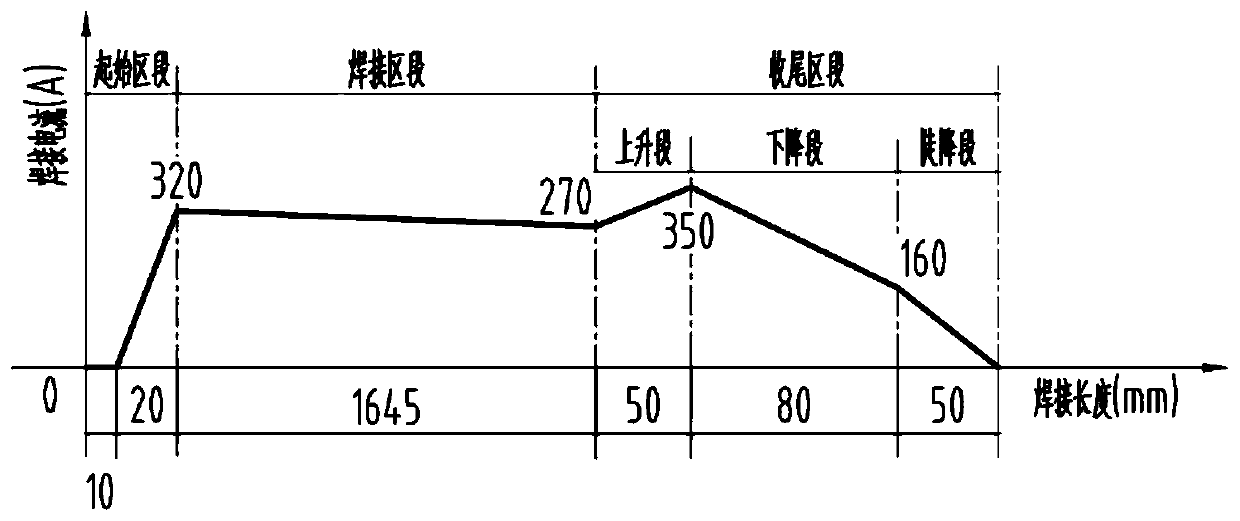

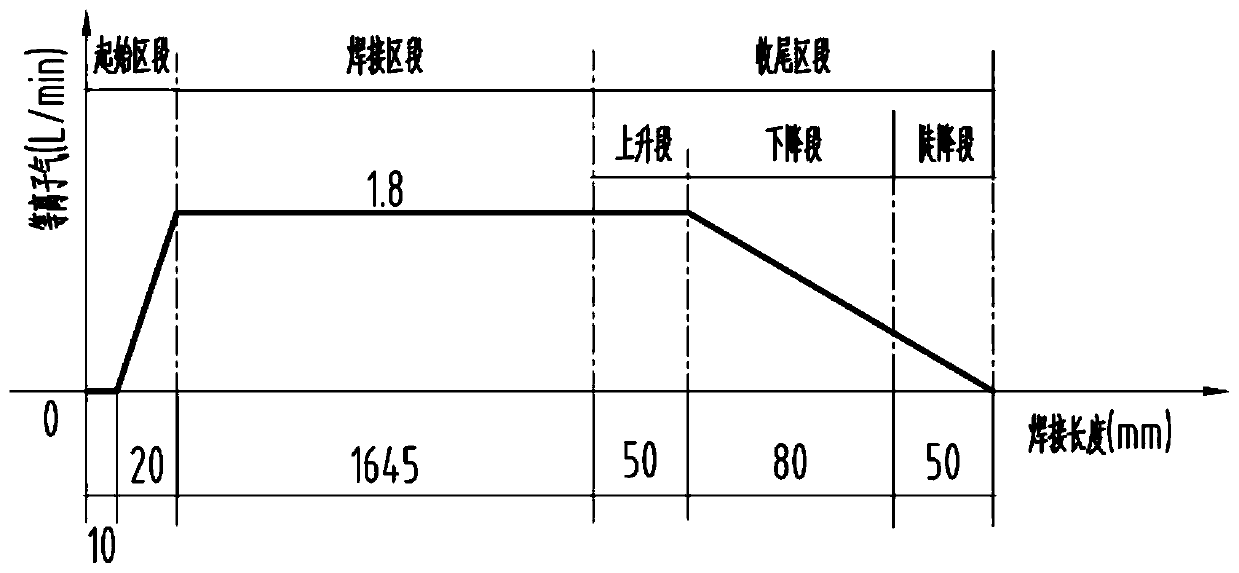

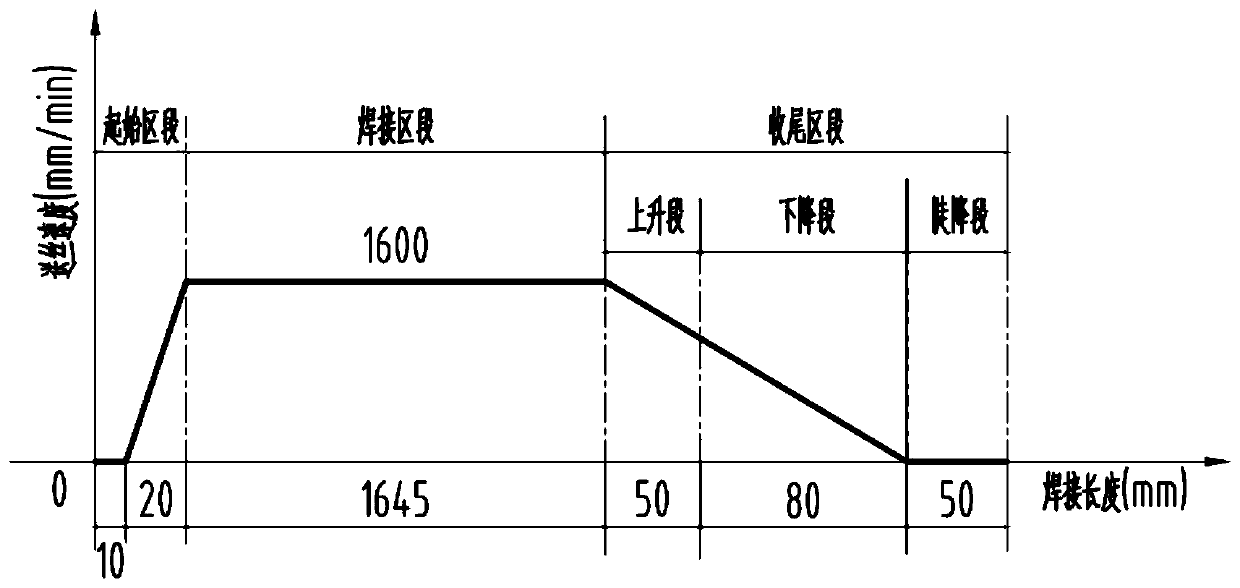

[0047] (1.3) The welding current, ion gas, and wire feeding speed continue to increase until they reach the normal welding current of 350A, ion air flow of 2.8scfh, and wire feeding speed of 2800mm / min. Normal welding starts and enters the welding section;

[0048] Step (2), circular seam welding section:

[0049] (2.1) The welding current in the normal welding section tends to decrease slowly and at a constant speed, and the total current drop from the beginning of welding to the end of the circular seam welding section is 30%;

...

Embodiment 3

[0057] A method for closing holes in plasma circular seam welding, comprising the steps of:

[0058] Step (1), the starting section of the circular seam:

[0059] (1.1) The protective gas is supplied for 8 seconds in advance.

[0060] (1.2) The welding current, ion gas, and weldment rotation start simultaneously, the welding current and ion gas rise, the weldment is perforated, the molten pool forms a small hole effect, and wire feeding starts;

[0061] (1.3) Welding current, ion gas, and wire feeding speed continue to increase until they reach the normal welding current of 200A, ion air flow of 1 scfh, and wire feeding speed of 1500mm / min. Normal welding starts and enters the welding section;

[0062] Step (2), circular seam welding section:

[0063] (2.1) The welding current in the normal welding section tends to decrease slowly and at a constant speed, and the total current drop from the beginning of welding to the end of the circular seam welding section is 15%;

[0064...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com