Coupled preparation technological method for aluminum alloy plates

An aluminum alloy sheet material and preparation technology, which is applied in the field of aluminum sheet raw rolling production, can solve problems such as inconsistent core surface quality, coarse center structure, and low strength and hardness, achieve high cooling intensity, improve core quality, and meet performance requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

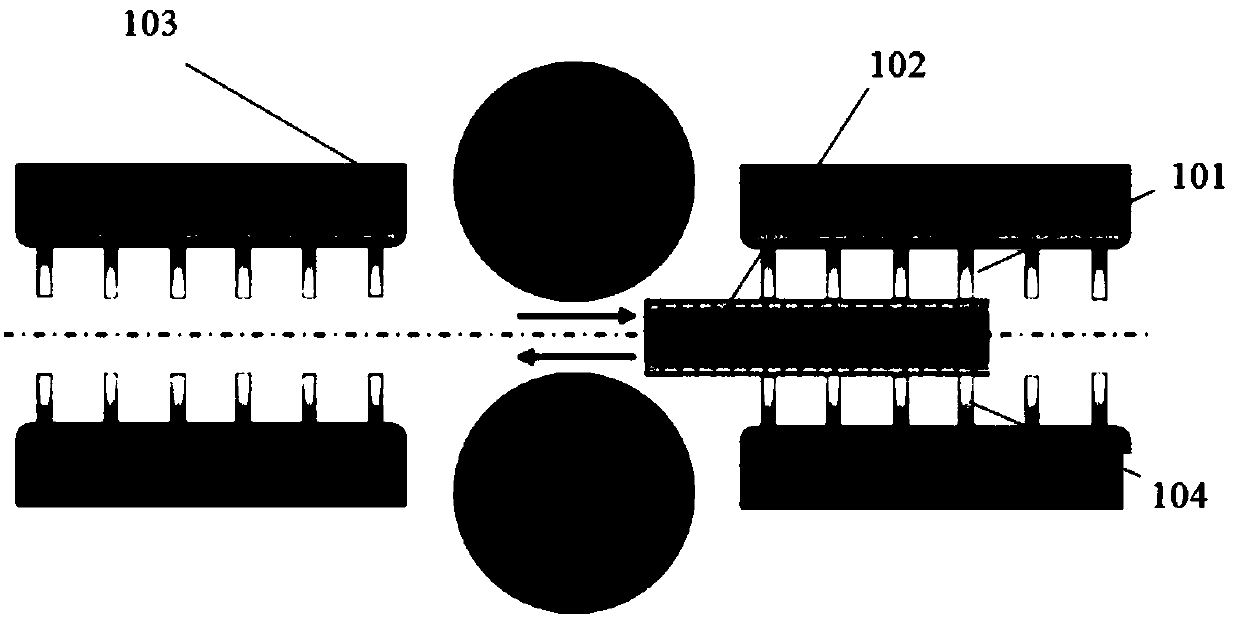

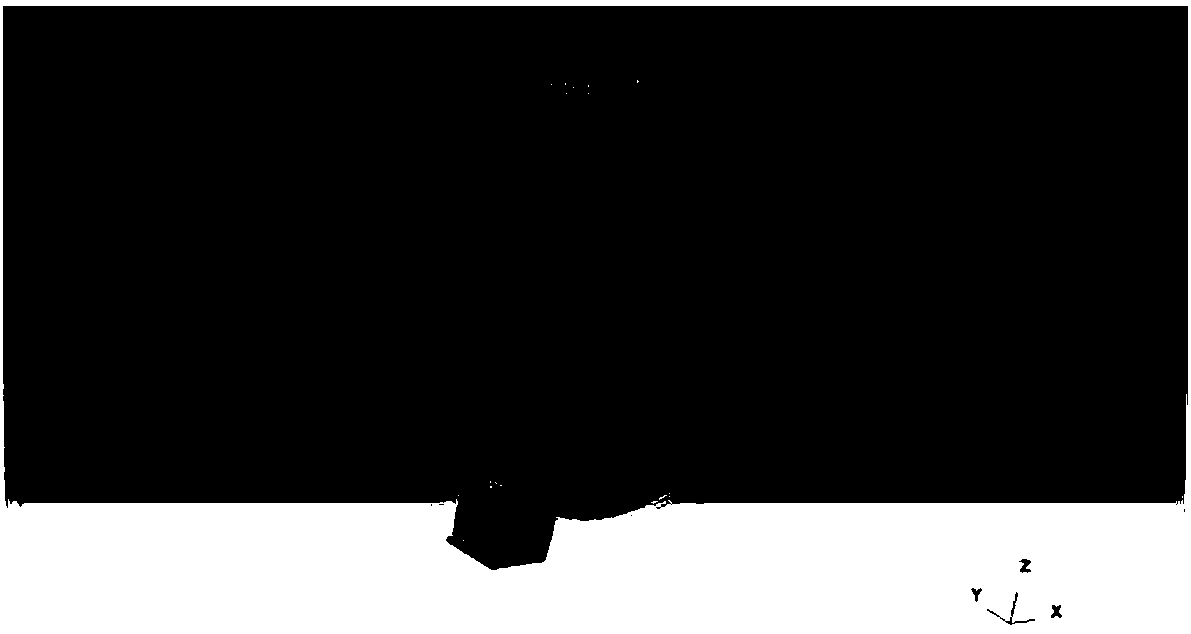

Method used

Image

Examples

example 1

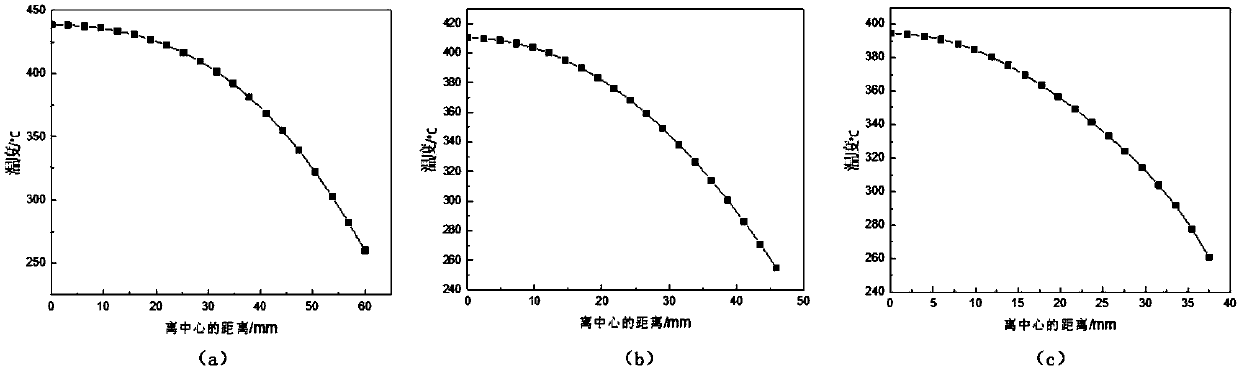

[0053] The 5182 aluminum alloy that has been heated at 450°C and held for 2.5 hours is used as the rolling material (thickness 120mm). The slab heated at ℃ and held for 2.5 hours is quickly transferred to the position of the rolling mill, the transfer time is shortened as much as possible, and the heat loss during the transfer process is reduced, and conventional rolling is carried out on a two-roll reversing rolling mill. Take part of the finished product and anneal at 370℃ / 2h. The structure of the surface layer, 1 / 4 and core is as follows: Figure 8 shown.

example 2

[0055] The 5182 aluminum alloy that has been heated at 450°C and held for 2.5 hours is used as the rolling material (thickness 120mm). The rolling procedure is 120→94→76→59→41→27→15→8.5→5 (mm), and the The slab is quickly transferred to the transfer roller of the rolling mill (due to the high thermal conductivity of aluminum, in order to maintain the temperature gradient in the thickness direction, it cannot stay for a long time after cooling before entering the rolling mill), open the cooling device, and let the slab pass through the cooling device with the roll , spray water to cool the upper and lower surfaces, the cooling time is 6s, measure the temperature of the surface through a temperature measuring instrument, cool the surface temperature to about 260°C, and then carry out rolling, the surface temperature after rolling is 310°C-320°C , under the cooling device on the other side, carry out the second pass of pre-rolling cooling, the cooling time is 3s, so that the surfa...

example 3

[0057] The 5182 aluminum alloy that has been heated at 450°C and held for 2.5 hours is used as the rolling material (thickness 120mm), and the rolling procedure is 120→100→82→68→56→48→38→30→23→16→9→5 (mm), quickly transfer the 120mm slab to the transfer roller of the rolling mill (due to the high thermal conductivity of aluminum, in order to maintain the temperature gradient in the thickness direction, it cannot stay for a long time after cooling before entering the rolling mill), turn on the cooling device, let the slab The billet passes through the cooling device with the roll, and the upper and lower surfaces are sprayed with water for cooling. The cooling time is 6s. The temperature of the surface is measured by a temperature measuring instrument, and the surface temperature is cooled to about 260°C, and then rolling is carried out. The surface temperature after rolling is At about 300°C, the second pass of pre-rolling cooling is carried out under the cooling device on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com