Novel drawing shell shearing device

A technology of shearing device and housing, which is applied in the field of battery production, can solve the problems of large battery cell leakage, large R angle deviation, four-side chamfering that cannot match the cover plate well, achieve good consistency, and improve CPK value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

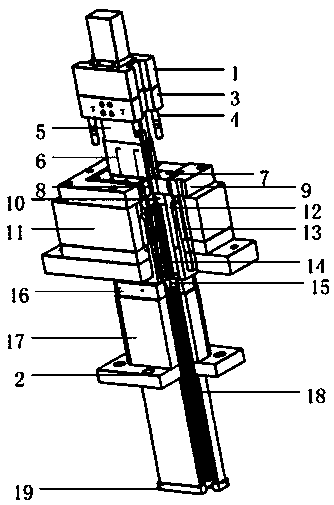

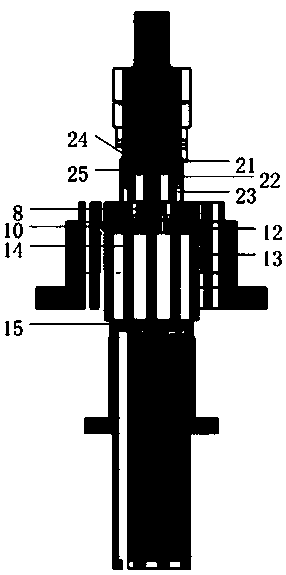

[0012] Such as figure 1 , 2 The novel deep-drawing shell shearing device of the present invention is shown, and its structure comprises upper die, lower die; Said upper die comprises shearing die handle 1, shearing fixing seat 3, shearing punch 5, shearing chip 6, The above components are fixed sequentially from top to bottom; the shear chip 6 is equipped with a return steel ball 21 and a return spring 22, one end of the return spring 22 is fixed to the return steel ball 21, and the other end is fixed to the nut part of the screw 23 , the other end of the screw 23 protrudes from the lower surface of the shear chip 6, the upper half of the return steel ball 21 exposes the upper surface of the shear chip 6, and the lower surface of the shear punch 5 is connected to the lower surface of the shear chip 6. The groove where the steel ball 21 matches, the shearing punch 5 and the shearing chip 6 are fixed by bolts 24 and gaskets 25; Shear die 7, shear ejector pin, described shear e...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap