Electronic waste friction electrostatic sorting device

A technology of electronic waste and sorting device, which is applied in the direction of electrostatic effect separation, solid separation, chemical instruments and methods, etc., can solve the problems of increasing cost, inconvenient measurement of charge, and inability to control the charge of electronic waste particles, achieving The effect of efficient sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

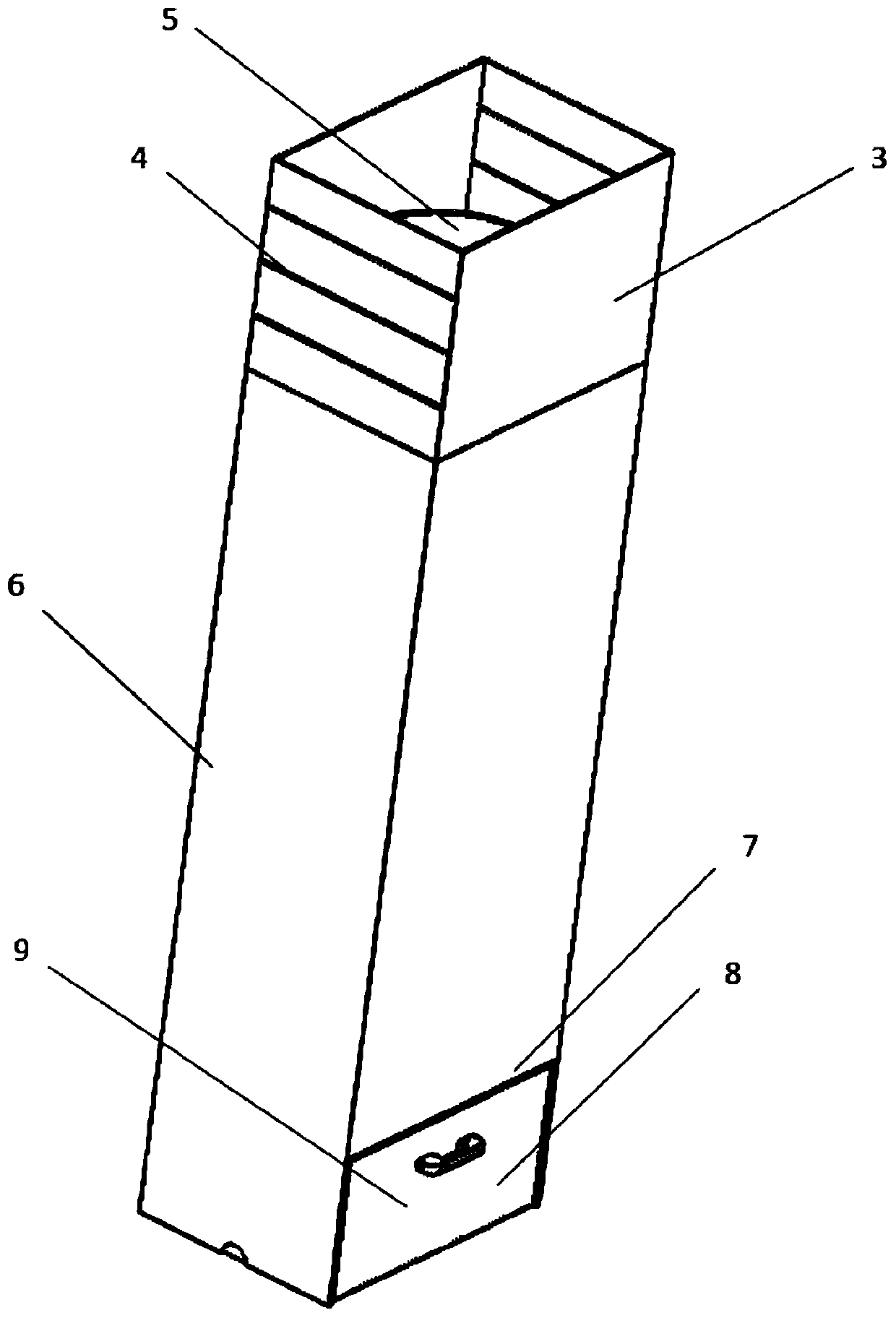

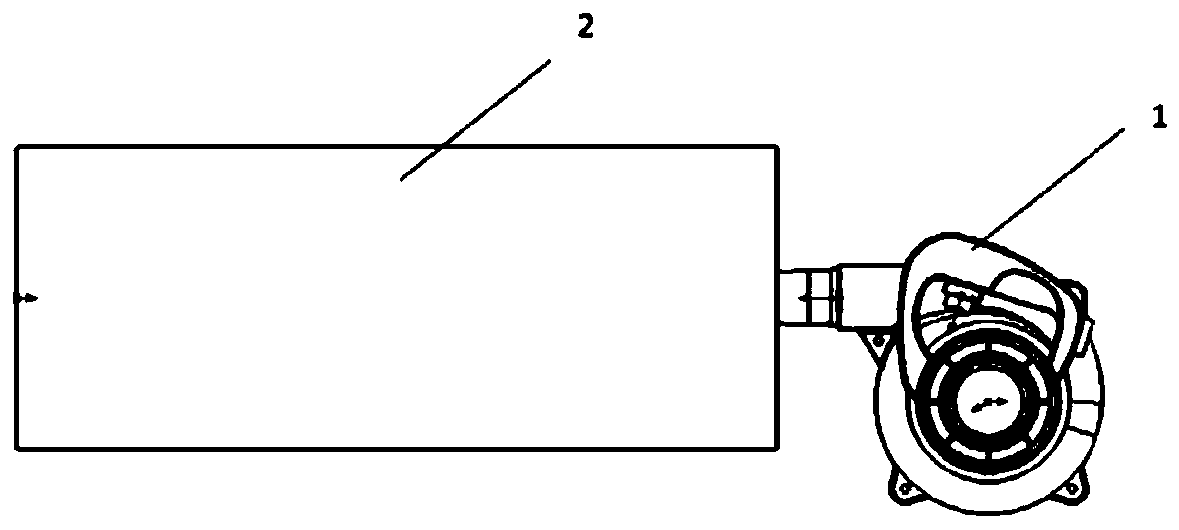

[0034] Such as Figure 1-2 As shown, the frictional electrostatic separation device mainly includes a blower 1, a plastic friction barrel 2, a bracket 3, a speed baffle 4, a feeding funnel 5, an acrylic protective cover 6, a pole plate 7, a collection bin 8, and a partition plate 9 . The acrylic plate protective cover 6 is placed on the ground, the pole plate 7 is glued inside the acrylic plate protective cover, and the collection bin 8 is placed under the protective cover 6, and the collection bin 8 is located below the electrostatic field formed by the polar plates, and the two partition plates 9 are placed In the collection bin 8, the partition plates 9 are respectively inserted into the slots at different positions within the scope of the falling points of the particle trajectories. The support 3 is placed above the acrylic protective cover 6, the speed baffle 4 can be placed inside the support 3, and the feeding funnel 5 is placed on the speed baffle 4. The blower 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com