Titanium metal-biological ceramic bone tissue engineering scaffold and preparation method thereof

A technology of bone tissue engineering and bioceramics, which is applied in the field of biomedical materials, can solve the problems of poor mechanical properties of pure bioceramic materials and insufficient biological activity of pure metal materials, so as to ensure biosafety, biocompatibility, and good structure. The effect of integrity, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

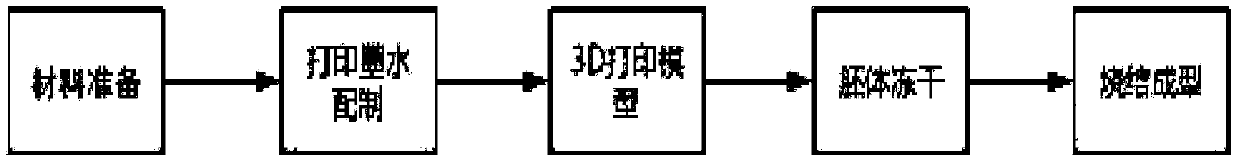

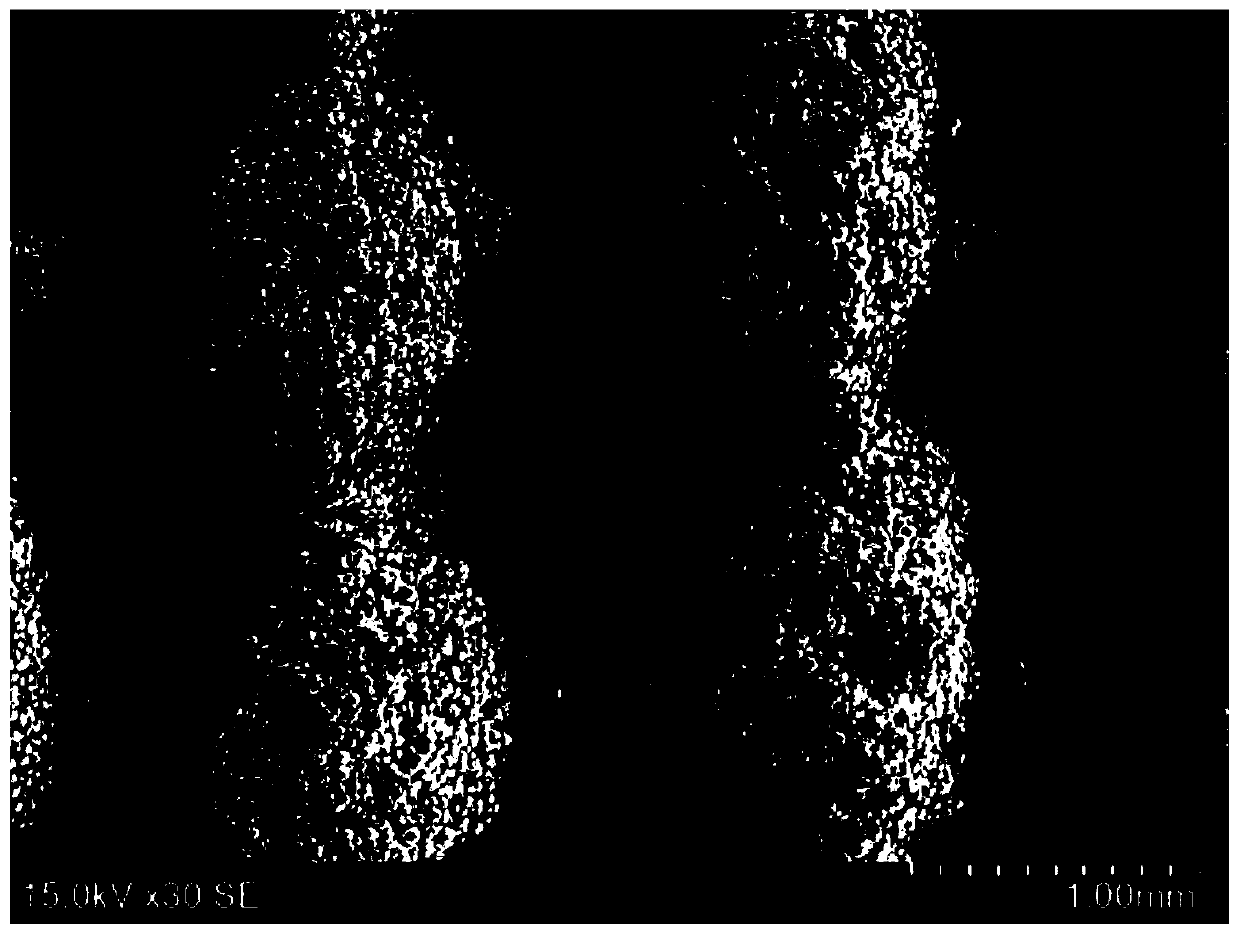

[0034] This embodiment provides the preparation method of the 3D printing titanium metal-bioceramic composite material and bone tissue engineering scaffold of the present invention, specifically:

[0035] According to the mass ratio of titanium alloy (Ti6Al4V) to hydroxyapatite (HA) being 75:25, 30 g of titanium alloy (Ti6Al4V) powder and 10 g of hydroxyapatite (HA) powder were taken. Take 50ml of deionized water and 38.5g of polyethylene glycol to prepare an aqueous solution, add 9ml of polyethylene glycol aqueous solution, 1ml+6 drops of glycerin, 10g of hydroxyapatite (HA) and 30g of titanium alloy in the defoamer (Ti6Al4V). Set the operating parameters of the defoamer: the first stage of powder mixing time is 1min, the speed is 500r / min, the defoaming time is 1min, and the speed is 1000r / min. In the second stage, the powder mixing time is 1min, the speed is 1000r / min, the defoaming time is 2min, and the speed is 1500r / min. Observe whether the ink is stirred evenly, other...

Embodiment 2

[0039] This embodiment provides the preparation method of the 3D printing titanium metal-bioceramic composite material and bone tissue engineering scaffold of the present invention, specifically:

[0040] The modeling, freeze-drying, and sintering process of the scaffold are the same as in Example 1, except that the 3D printing ink raw material is prepared in a different material batching method from that in Example 1. According to this embodiment, the mass ratio of titanium alloy (Ti6Al4V) to biphasic apatite (BCP) is 75:25, 40 g of titanium alloy (Ti6Al4V) powder and 10 g of biphasic apatite (BCP) are taken. Get 50ml deionized water and 38.5g Polyethylene Glycol to be mixed with aqueous solution, add 7.5ml Polyethylene Glycol aqueous solution, 0.5ml+5 drops of glycerol, 10g biphasic apatite (BCP) and 40g titanium alloy (Ti6Al4V). The parameter of defoamer is identical with example 1, until stirring evenly. Finally, it is freeze-dried and then sintered into shape.

[0041]...

Embodiment 3

[0043] This embodiment provides the preparation method of the 3D printing titanium metal-bioceramic composite material and bone tissue engineering scaffold of the present invention, specifically:

[0044] The modeling, freeze-drying, and sintering process of the scaffold are the same as in Example 1, except that the 3D printing ink raw material is prepared in a different material batching method from that in Example 1. According to this embodiment, the mass ratio of titanium alloy (Ti6Al4V) to tricalcium phosphate (TCP) is 75:25, 40 g of titanium alloy (Ti6Al4V) powder and 10 g of tricalcium phosphate (TCP) are taken. Take 50ml of deionized water and 38.5g of polyethylene glycol to prepare an aqueous solution, add 7.5ml of polyethylene glycol aqueous solution, 0.5ml+5 drops of glycerin, 10g of tricalcium phosphate (TCP) and 40g of titanium in the defoamer alloy (Ti6Al4V). The parameter of defoamer is identical with example 1, until stirring evenly. Finally, it is freeze-drie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com