Halogen-free flame-retardant epoxy prepreg and composite material thereof

A composite material and prepreg technology, which is applied in the field of halogen-free epoxy resin composition and prepreg and composite materials containing the resin, can solve the problem that the flame retardant level cannot meet the flame retardant requirements of the rail transit field, and achieve The effect of good viscosity, good mechanical properties and good manufacturability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Preparation of flame retardant resin

[0043] Mix 5 parts of DICY and 10 parts of NPEL-128 uniformly to prepare component B, mix 5 parts of U-24 and 10 parts of NPEL-128 uniformly to obtain component C; mix 5 parts of NPEL-128 and 55 parts of NPPN -638S, 20 parts of SEN-6065, 5 parts of PVF were dissolved at 150°C and mixed evenly, cooled to 70-80°C, then 20 parts of Doher601R, 20 parts of Doher6002A and 50 parts of aluminum hydroxide were added, stirred and mixed evenly to obtain Component A: add B and C components to A component, mix well to get flame retardant epoxy resin.

[0044] (2) Prepreg preparation

[0045] The prepreg is prepared by a one-step method, the resin is glued at 70°C, the fiber is 200g / m2 carbon fiber fabric, and the resin content is 45%.

[0046] (3) Composite material preparation

[0047]Cut the prepreg into 1000mm×1000mm, lay it up, make a vacuum bag, vacuum pressure ≥ 0.085MPa, put the prepreg into the autoclave, press 0.6MPa, cure at 14...

Embodiment 2~9

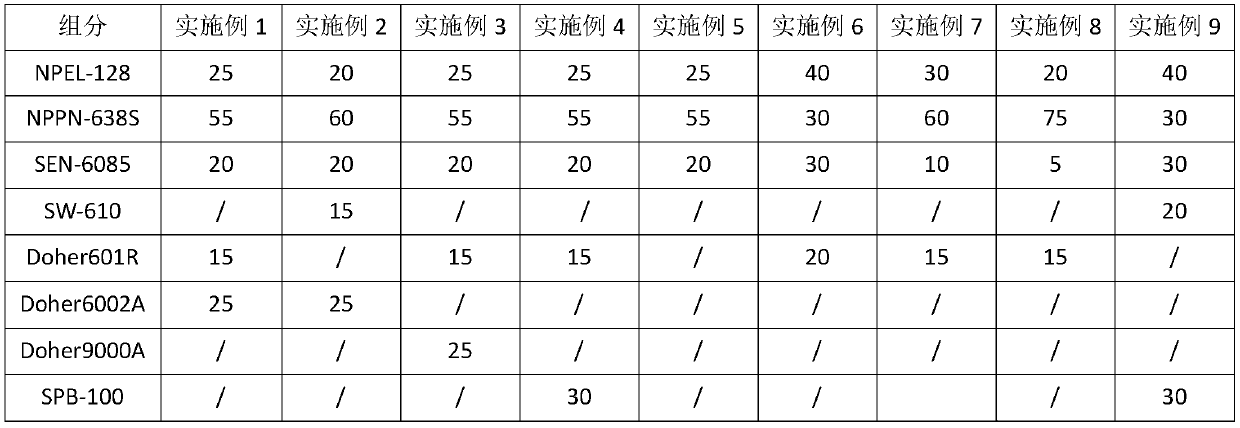

[0049] The preparation methods of Examples 2-9 are similar to those of Example 1, only the composition and dosage of the resin formulation are changed, and the matrix is shown in Table 1.

[0050] Table 1

[0051]

[0052]

[0053] Flame retardant performance is tested according to DIN 5510-2 standard; bending strength is tested according to ASTM D7264 standard, and shear strength is tested according to ASTM D2344 standard.

[0054] The flame retardant prepreg prepared in the above examples has good process performance, and the composite materials prepared by using the flame retardant epoxy prepreg all have excellent flame retardant performance and good mechanical strength, which can meet the requirements of fire prevention in rail transit, etc. demanding areas.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com