Sheet material, preparation method and use method

A technology of sheet and mass, applied in the field of building materials, can solve the problems of human health damage and high formaldehyde emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

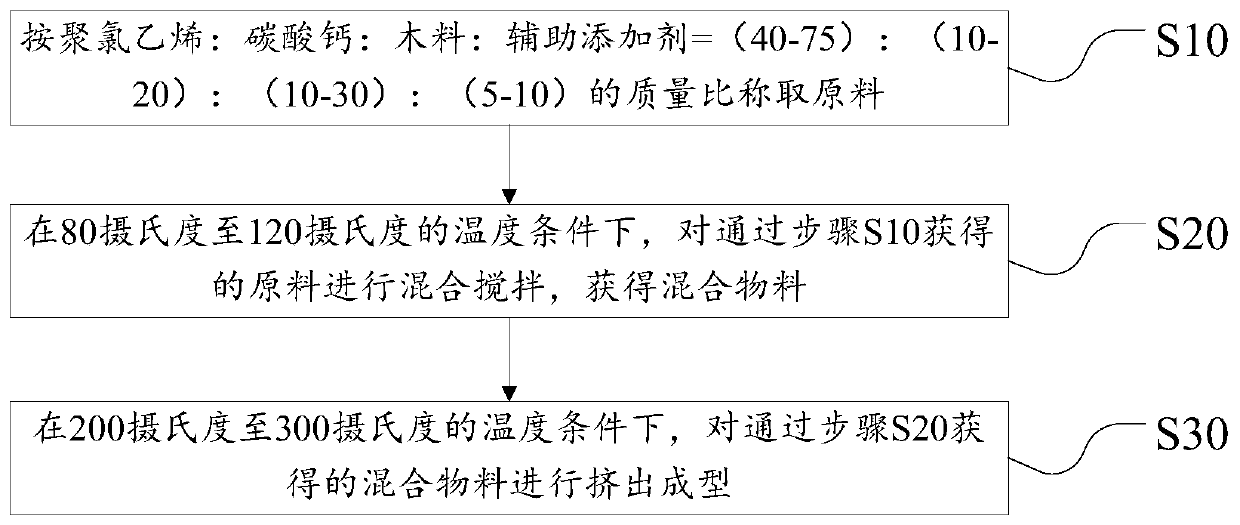

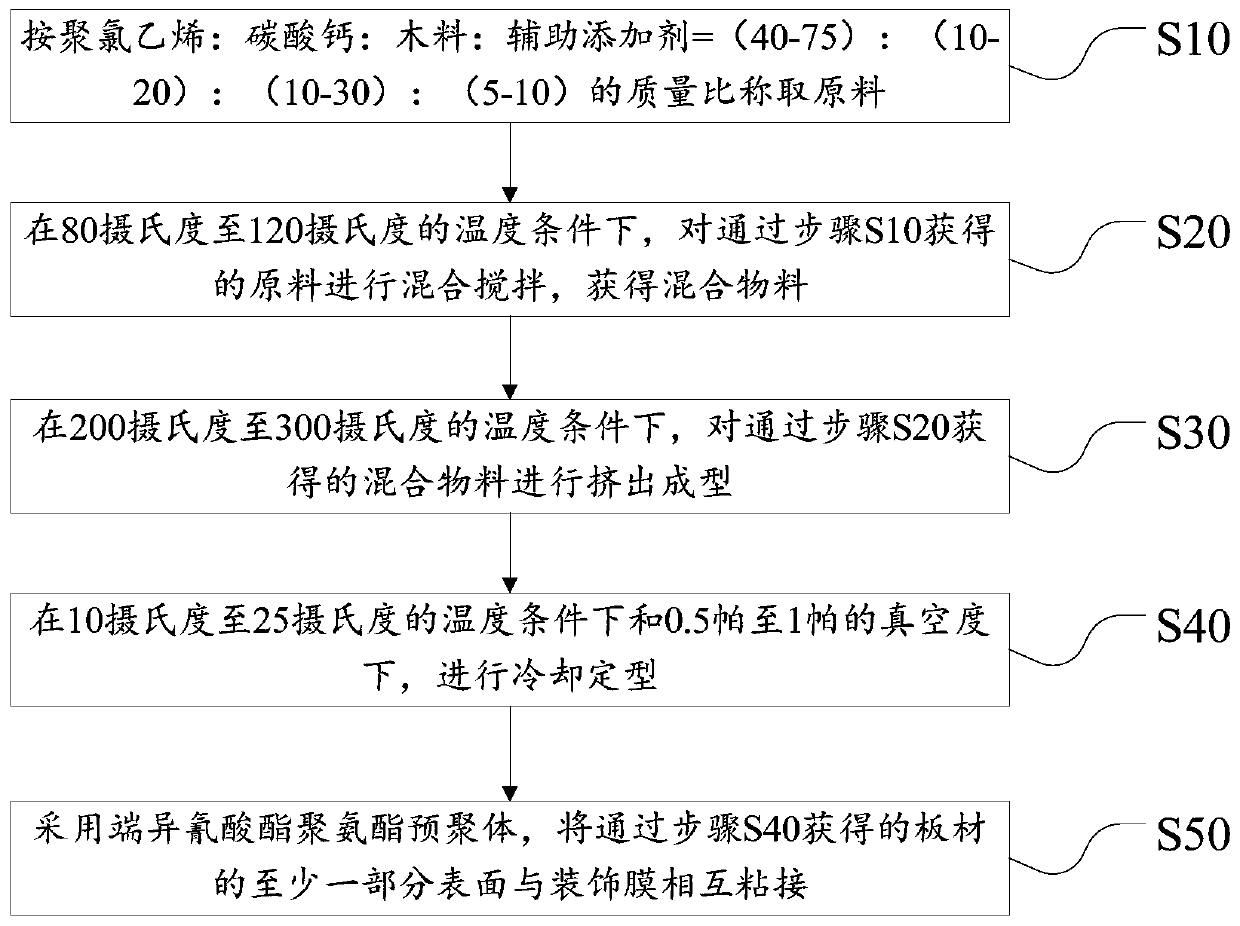

Method used

Image

Examples

Embodiment 1

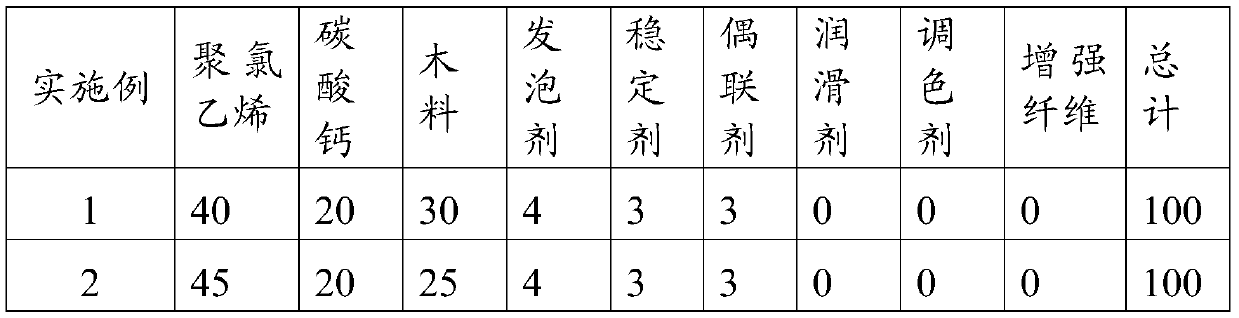

[0073] This embodiment provides a board, wherein the raw material composition and preparation method of the board are as follows.

[0074] As shown in Table 1 and Table 2, the raw materials were weighed according to the mass ratio of polyvinyl chloride: calcium carbonate: wood: auxiliary additive = 40:20:30:10. Under the temperature condition of 80 degrees Celsius, the raw materials are mixed and stirred to obtain the mixed materials. Under the temperature condition of 200 degrees Celsius, the mixed material is extruded to obtain a composite sheet. Among them, the auxiliary additives include: foaming agent, stabilizer and coupling agent, and the mass ratio of the three is: foaming agent:stabilizer:coupling agent=4:3:3. The foaming agent in this embodiment is an azodicarbonamide foaming agent, the stabilizer is a dibutyltin stabilizer, and the coupling agent is a titanate coupling agent.

Embodiment 2

[0076] This embodiment provides a board, wherein the raw material composition and preparation method of the board are as follows.

[0077] As shown in Table 1 and Table 2, the raw materials were weighed according to the mass ratio of polyvinyl chloride: calcium carbonate: wood: auxiliary additive = 45:20:25:10. Under the temperature condition of 90 degrees Celsius, the raw materials are mixed and stirred to obtain the mixed materials. Under the temperature condition of 210 degrees Celsius, the mixed material is extruded to obtain a composite sheet. Among them, the auxiliary additives include: foaming agent, stabilizer and coupling agent, and the mass ratio of the three is: foaming agent:stabilizer:coupling agent=4:3:3. The foaming agent in this embodiment is an azodicarbonamide foaming agent, the stabilizer is a dioctyltin stabilizer, and the coupling agent is a silane coupling agent.

Embodiment 3

[0079] This embodiment provides a board, wherein the raw material composition and preparation method of the board are as follows.

[0080] As shown in Table 1 and Table 2, the raw materials were weighed according to the mass ratio of polyvinyl chloride: calcium carbonate: wood: auxiliary additive = 50:15:25:10. Under the temperature condition of 100 degrees Celsius, the raw materials are mixed and stirred to obtain the mixed materials. Under the temperature condition of 220 degrees Celsius, the mixed material is extruded to obtain a composite sheet. Among them, auxiliary additives include: foaming agent, stabilizer, coupling agent, lubricant, toner and reinforcing fiber. The mass ratio of each component in the auxiliary additive is: foaming agent: stabilizer: coupling agent: lubricant: toner: reinforcing fiber = 1.5:1.5:1.5:1.5:2:2. The foaming agent of the present embodiment is an azodicarbonamide foaming agent, the stabilizer is a dioctyltin stabilizer, the coupling agent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com