Preparation method of industrial molybdenum oxide chemical standard sample

A technology of industrial molybdenum oxide and standard samples, which is applied in the preparation, sampling, and scientific instruments of test samples, can solve the problems of no standard samples, etc., and achieve the effects of wide application range, precise determination method, and reliable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

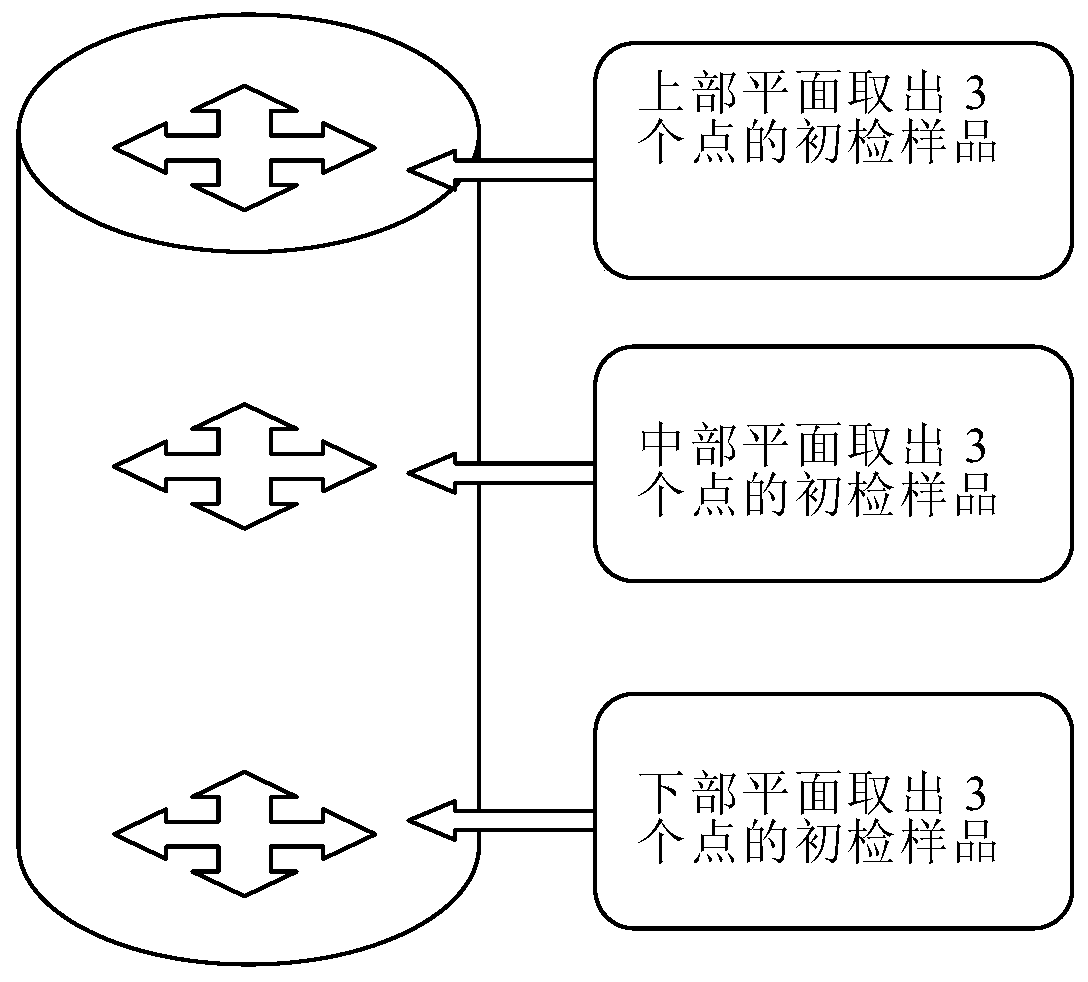

Method used

Image

Examples

Embodiment 1

[0038] This embodiment includes the following steps:

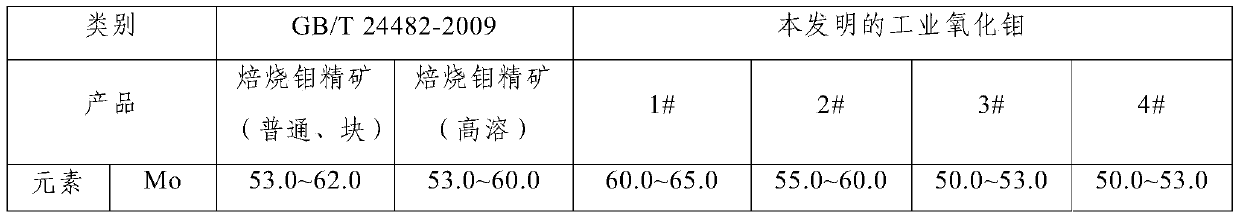

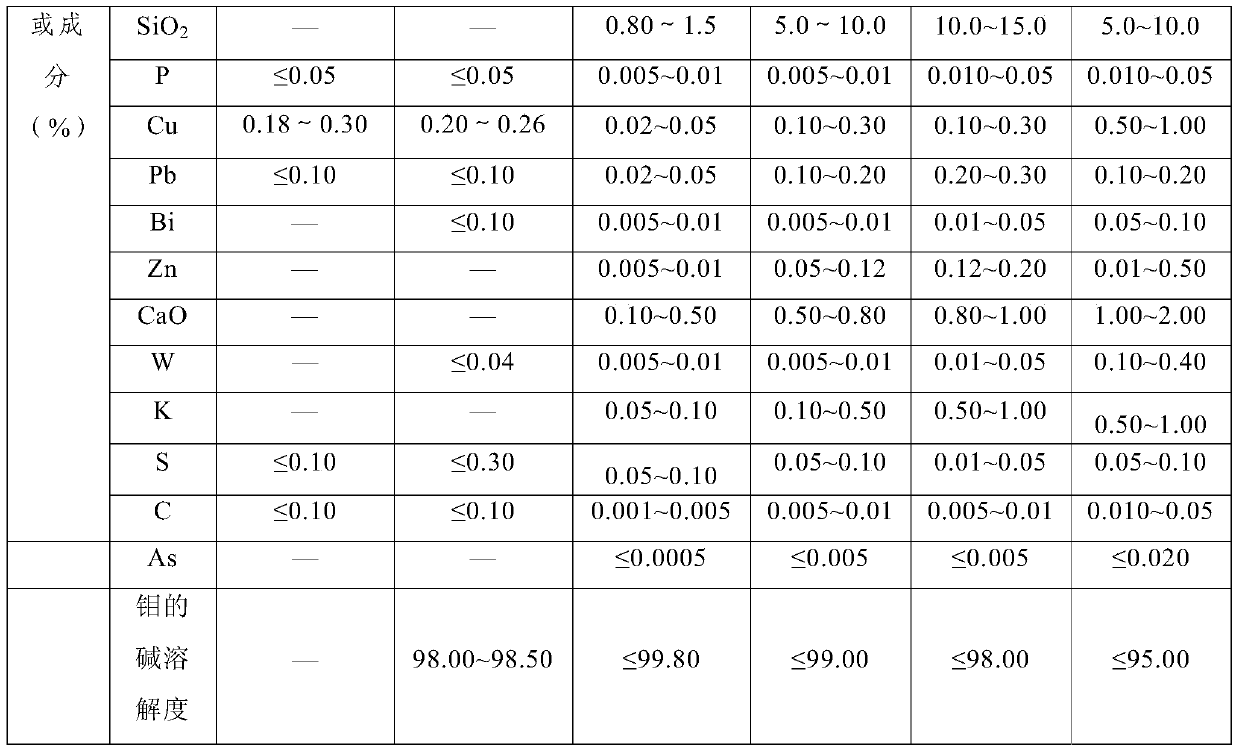

[0039] Step 1: Analyze the particle size of industrial molybdenum oxide with a laser particle size distribution analyzer, select industrial molybdenum oxide with a particle size of less than 150 μm as the raw material, and then use a 30B high-efficiency pulverizer to grind and crush the raw material. The feeding speed is 2kg / m, and each batch of feeding The amount is 100kg, and then the ZS-650 type high-efficiency vibrating sieve (equipped with a standard sieve with an aperture of 75 μm) is sieved to obtain an undersize powder with a particle size less than 75 μm; the chemical composition and content of the industrial molybdenum oxide are as follows in Table 2 shown.

[0040] Chemical composition and mass content in the industrial molybdenum oxide of table 2 embodiment 1

[0041] element or ingredient Mo SiO 2

P Cu Pb Mass content (%) 60.0~65.0 0.80~1.5 0.005~0.01 0.02~0.05 0.02~0.05 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com