Ditellurium-containing degradable polycarbonate polyurethane and preparation method thereof

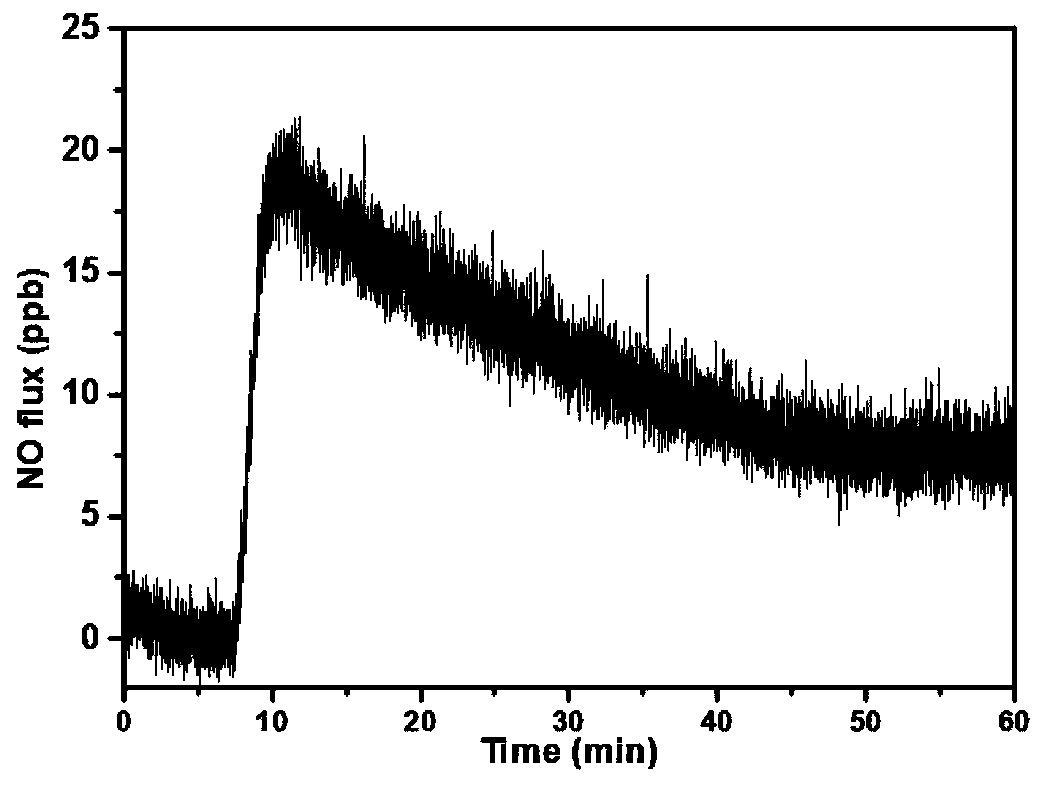

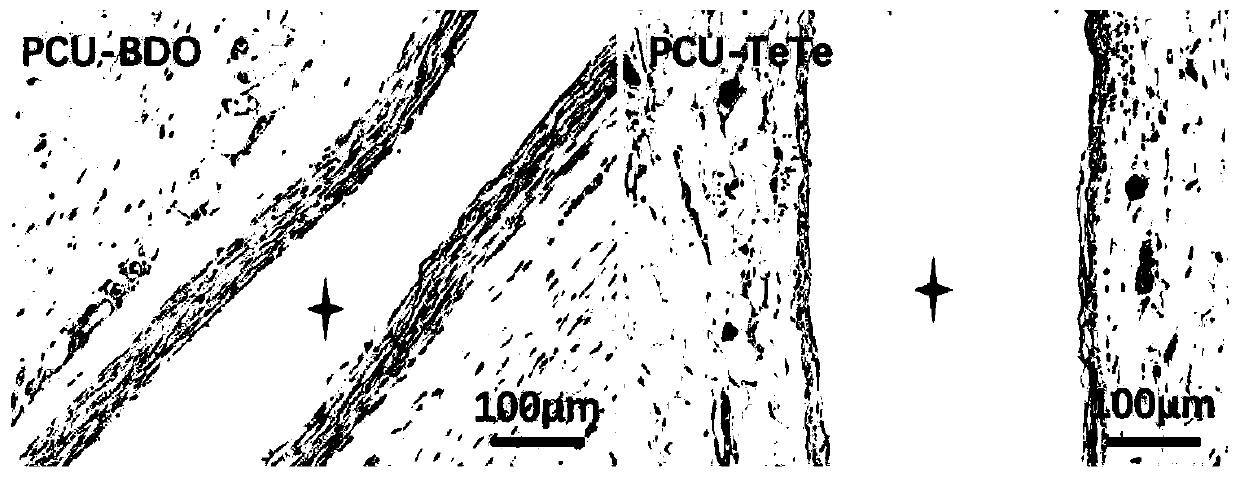

A technology of polycarbonate and polycarbonate II, which is applied in the field of degradable polycarbonate polyurethane and its preparation, can solve problems such as limited application and inability to respond intelligently, and achieve controllable structure, reduced activation and adhesion, and good removal The effect of oxygen free radical capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

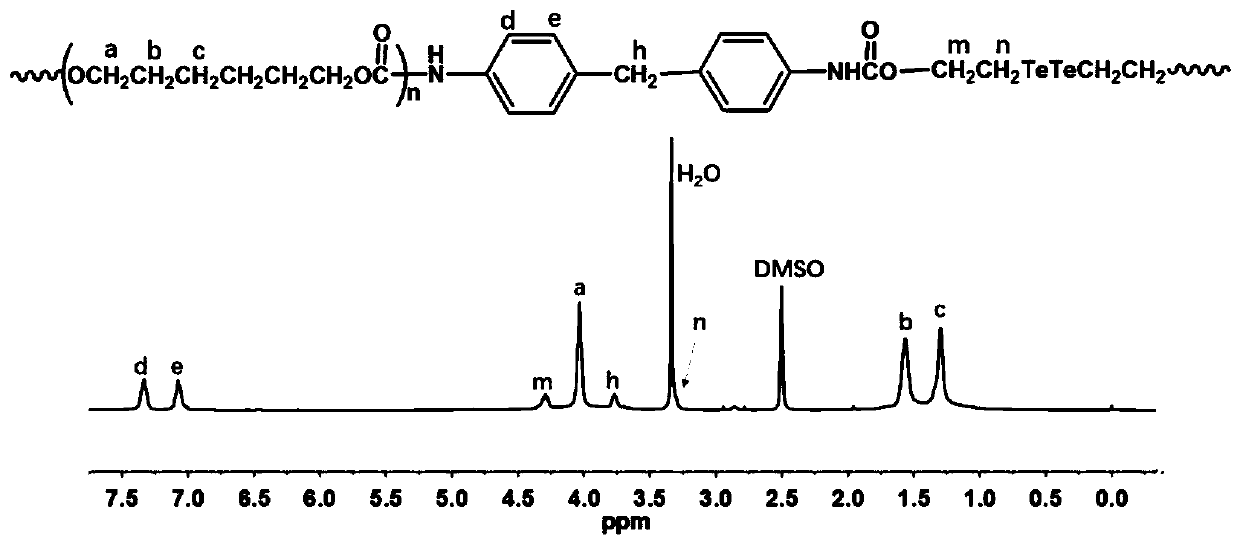

[0028] Preparation of ditellurium-containing polycarbonate polyurethane (PCU-TeTe):

[0029]

[0030] Step 1. Pre-dewater 1,6-hexanediol polycarbonate diol (PCDL, 5g, 1kDa) at 100°C for 3h under vacuum, and add 2.56g of MDI to the reaction containing PCDL under the protection of argon. In the device, stir at 60°C for 2 hours to obtain a prepolymer;

[0031] Step 2. Weigh 1.75g of ditelluridediethanol and dissolve it in 80ml of dry N,N-dimethylacetamide (DMAc), inject the solution into the reactor with a syringe, mix it with the prepolymer and add 1 ‰ of stannous octoate. After continuing to stir and react at 70°C for 10 hours, slowly transfer the reaction solution to 1L of methanol for precipitation, and repeatedly wash the solid with methanol and ethanol for 2 to 3 times, then dry it in a vacuum oven to obtain ditellurium-containing polycarbonate Polyurethane, and named PCU-TeTe.

[0032] According to the method described in step 1 and step 2, an equivalent amount of 1,...

Embodiment 2

[0048] Preparation of ditellurium-containing polycarbonate polyurethane (PCU-I-TeTe):

[0049]

[0050] Step 1. Pre-dewater 1,6-hexanediol polycarbonate diol (PCDL, 5g, 1kDa) at 100°C for 3h under vacuum. Under the protection of argon, add 2.67g IPDI to the reaction containing PCDL In the device, stir at 60°C for 2 hours to obtain a prepolymer;

[0051] Step 2. Weigh 1.75g of ditelluridediethanol and dissolve it in 80ml of dry DMAc, inject the solution into the reactor with a syringe, mix it with the prepolymer evenly, and then add 2‰ of stannous octoate. After continuing to stir and react at 70°C for 8 hours, slowly transfer the reaction solution to 1L of methanol for precipitation, wash the solid with methanol and ethanol for 2 to 3 times, and then dry it in a vacuum oven to obtain ditellurium-containing polycarbonate Polyurethane, and named PCU-I-TeTe.

Embodiment 3

[0053] Preparation of ditellurium-containing polycarbonate polyurethane (PCU-HM-TeTe):

[0054]

[0055] Step 1. Pre-dewater 1,6-hexanediol polycarbonate diol (PCDL, 10g, 2kDa) at 100°C for 3h under vacuum, and add 2.68g of HMDI to the reaction containing PCDL under the protection of argon. In the device, stir at 60°C for 2 hours to obtain a prepolymer;

[0056] Step 2. Weigh 1.75g of ditelluridediethanol and dissolve it in 120ml of dry DMAc, inject the solution into the reactor with a syringe, mix it with the prepolymer evenly, and then add 3‰ of stannous octoate. After continuing to stir and react at 70°C for 7 hours, slowly transfer the reaction solution to 1L of methanol for precipitation, wash the solid with methanol and ethanol for 2 to 3 times, and then dry it in a vacuum oven to obtain ditellurium-containing polycarbonate Polyurethane, and named PCU-HM-TeTe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com