Neodymium-iron-boron alloy powder, neodymium-iron-boron magnet material, preparation method and application

A technology of alloy powder and neodymium iron boron, which is applied in the fields of magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve the problems that the performance of magnet materials cannot be significantly improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

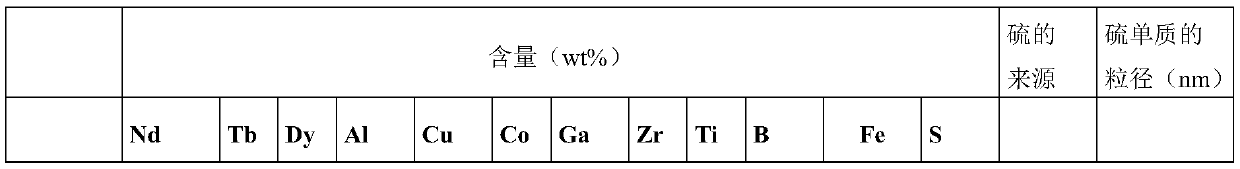

Embodiment 1

[0114]According to the composition and content of the NdFeB alloy powder listed in Example 1 in Table 1, the thickness of the corresponding no added sulfur element is 0.3mm NdFeB alloy casting sheet, and the alloy casting sheet is under the hydrogen pressure of 0.08MPa After saturated hydrogen absorption and internal dehydrogenation at 500°C, it is further refined to a particle size of 4 μm by jet milling in the mill chamber of a jet mill with an oxygen content below 15 ppm; among them, the sorting wheel in the jet mill process The rotating speed is 4000rpm / min. Then in this powder, add the 0.11wt% sulfur simple substance that particle diameter is 100nm to obtain mixture, then make the NdFeB alloy powder containing sulfur element listed in Example 1 in Table 1 after the mixture is mixed on a three-dimensional mixer for 3h ; Sulfur-containing NdFeB alloy powders were sequentially oriented in a magnetic field above 1.8T, sintered at 1070°C for 6 hours, and heat-treated at 500°C ...

Embodiment 3

[0116] According to the composition and content of the neodymium-iron-boron alloy powder listed in embodiment 3 in table 1, it is the neodymium-iron-boron alloy casting sheet that the thickness that does not add sulfur element is 0.3mm to prepare corresponding, this neodymium-iron-boron alloy casting sheet is at 0.08 After saturated hydrogen absorption under the hydrogen pressure of MPa, dehydrogenation within 500°C, and then further refinement by jet mill in the mill chamber of jet mill with oxygen content below 15ppm, 35ml / min to feed SO into the mill chamber 2 gas to obtain sulfur-containing neodymium-iron-boron alloy powder with a particle size of 4 μm, wherein the rotating speed of the sorting wheel in the jet milling process is 4000 rpm / min. Sulfur-containing NdFeB alloy powders were oriented in a 2T magnetic field, sintered at 1080°C for 6 hours, and heat-treated at 500°C for 6 hours to obtain sulfur-containing NdFeB magnet materials.

Embodiment 4

[0118] The composition and content of Nd-Fe-B alloy powder listed in Example 4 in Table 1 are prepared to correspond to the Nd-Fe-B alloy casting sheet with a thickness of 0.3mm without adding sulfur element, and the Nd-Fe-B alloy casting sheet is 0.08 After saturated hydrogen absorption under MPa hydrogen pressure, dehydrogenation at 500°C, and then further refined by jet mill in the mill chamber of jet mill with oxygen content below 15ppm, 71ml / min to feed SO into the mill chamber 2 gas to obtain sulfur-containing neodymium-iron-boron alloy powder with a particle size of 4 μm, wherein the rotating speed of the sorting wheel in the jet milling process is 4000 rpm / min. Sulfur-containing NdFeB alloy powders were oriented in a 2T magnetic field, sintered at 1080°C for 6 hours, and heat-treated at 500°C for 6 hours to obtain sulfur-containing NdFeB magnet materials.

[0119] The neodymium-iron-boron magnet material of embodiment 2,5~10, comparative example 1~3,5 and 6 is accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com