An indirect resistance heating device for additive manufacturing wire feeding process

A resistance heating and additive manufacturing technology, used in additive processing, manufacturing tools, resistance welding equipment, etc., can solve the problems of unhealthy operators, limited application scope, low heating efficiency, etc., to achieve reliable heating effect, The effect of improving heating efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

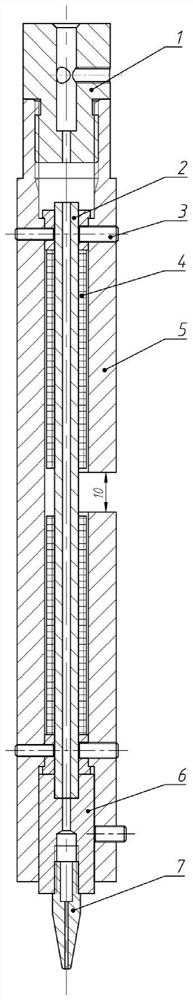

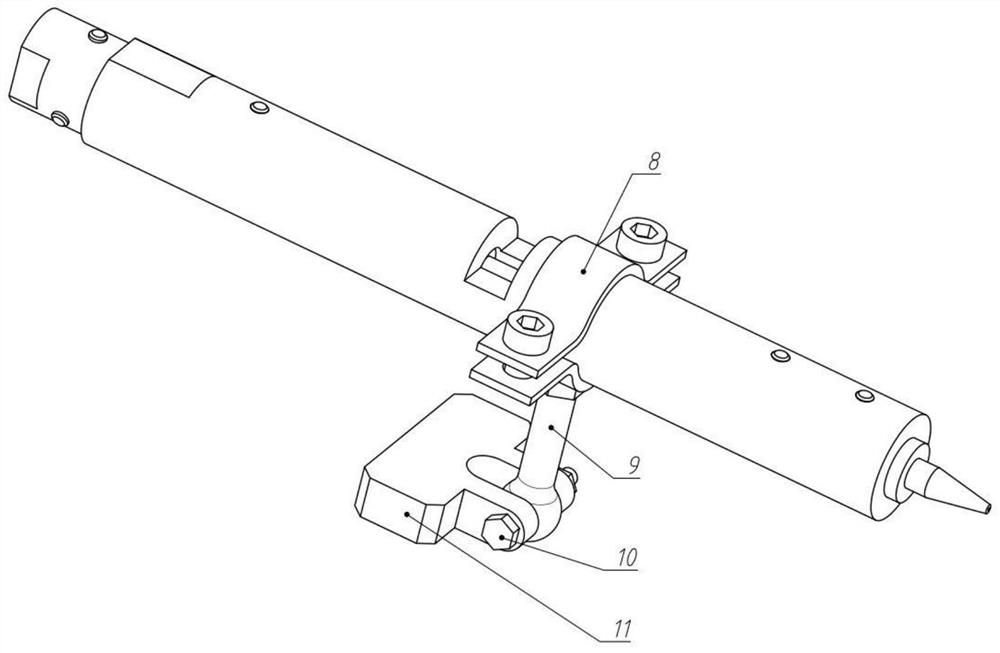

[0043] This embodiment describes the specific implementation of an indirect resistance heating device for additive manufacturing wire feeding process proposed by the present invention, as shown in the attached figure 1 and figure 2 shown.

[0044] figure 1 Among them, 1 is the wire feeding hose joint, 2 is the heat pipe, 3 is the set screw, 4 is the soldering iron core, 5 is the shell casing, 6 is the wire feeding nozzle joint, and 7 is the wire feeding nozzle.

[0045] figure 2 Among them, 8 is a pipe bracket with a nut, 9 is a swing bolt, 10 is a bolt and nut fastening assembly, and 11 is a base.

[0046] The indirect resistance heating device in the wire feeding process of additive manufacturing includes: a shell sleeve assembly, an indirect resistance heating wire assembly, a wire feeding hose joint 1, a wire feeding nozzle joint 6, a wire feeding nozzle 7, and a bolt and nut fastening assembly 10 and base 11.

[0047] The shell sleeve assembly includes a shell sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com