Waste incineration flue gas purification method and system

A flue gas purification system and waste incineration technology, applied in the field of flue gas purification, can solve problems such as difficult to meet the requirements, achieve the effects of reducing power consumption, reducing system pressure drop, and high denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

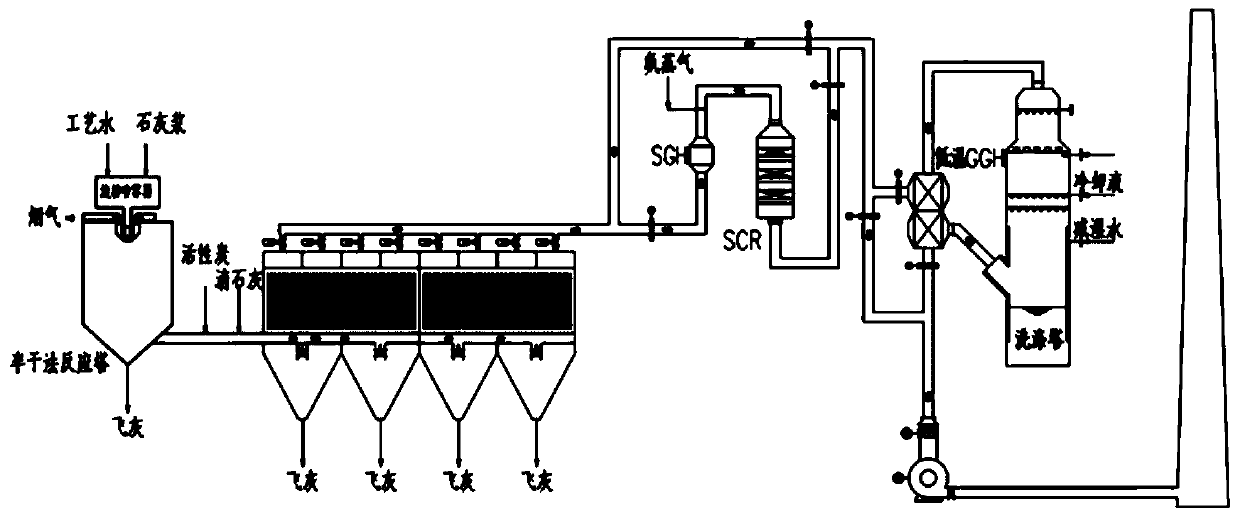

[0058] Such as figure 1 Shown is a schematic diagram of the garbage incineration flue gas purification system of the present invention, and the structure and treatment method of the system are described in conjunction with the accompanying drawing.

[0059] Such as figure 1 As shown, the ammonia water nozzle of the SNCR system is installed on the first flue of the boiler at the outlet of the waste incinerator, and the high temperature environment in the flue is used to inject ammonia water for denitrification reaction, and the NO in the flue gas x Reduce the concentration and ensure that the concentration at the outlet of the waste heat boiler is controlled at 200mg / Nm 3 the following.

[0060] The flue gas (about 195°C) at the outlet of the waste heat boiler enters the semi-dry reaction tower for the first step of deacidification treatment. Slaked lime is made into lime slurry through a pulping system, and sprayed into the reaction tower through a rotary atomizer. The flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com