Porous nanosheet based NiCo2O4 nanotubes applied to high-effective carbon soot catalytic elimination

A technology of nanosheets and nanotubes, which is applied in the field of porous nanosheet-based NiCo2O4 nanotube structure materials and their preparation, which can solve problems such as hindering applications, aggregation and sintering of two-dimensional nanosheets, and achieve low cost and good soot removal performance , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

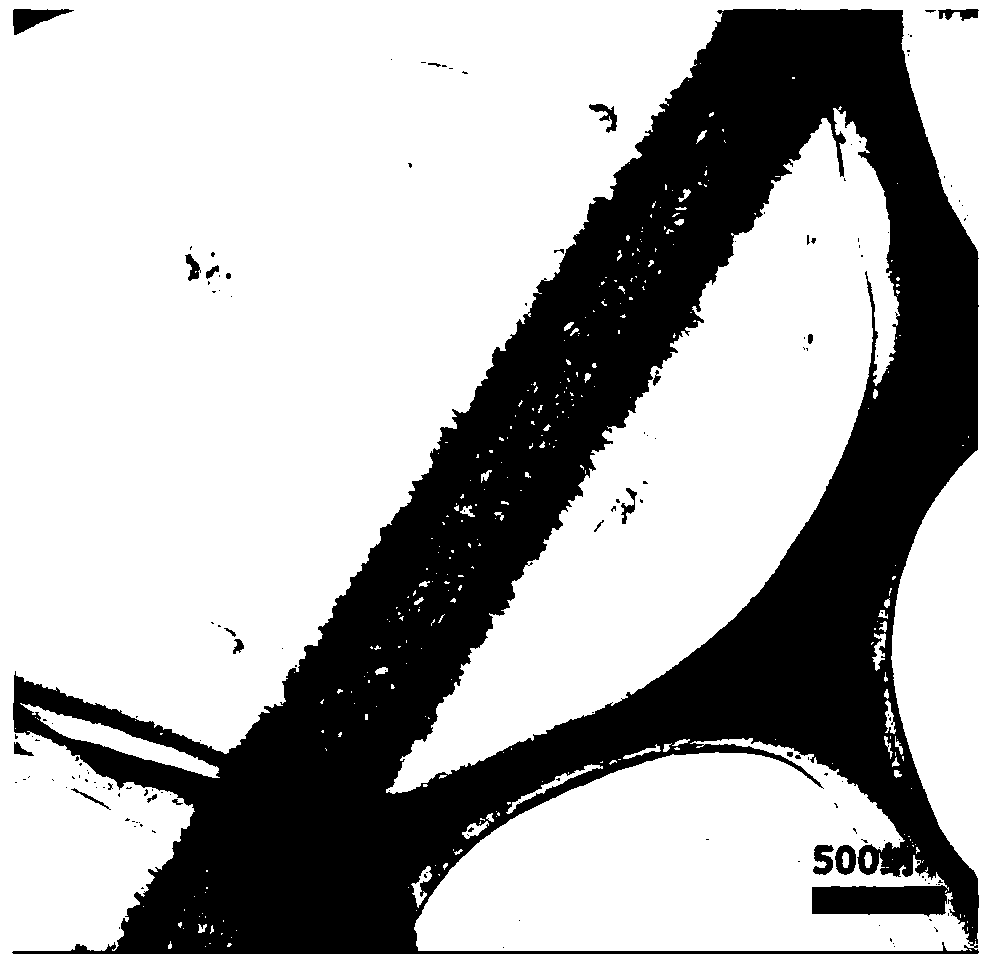

Image

Examples

Embodiment 1

[0037] Step 1: Weigh 0.40g of L-aspartic acid and 0.83g of cobalt nitrate in a 50mL autoclave, add 15mL of deionized water and 15mL of ethylene glycol, stir magnetically at room temperature for 30 minutes, and then continue to mix Add 3mL of 2mol / L sodium hydroxide aqueous solution dropwise into the solution until the solution turns transparent brownish-red and the pH is 6.5. After continuing magnetic stirring at room temperature for 1 hour, it is sealed and placed in an oven at 180°C for 5 hours.

[0038] Step 2: After the temperature of the autoclave in step 1 is cooled, the supernatant is poured off, the pink precipitate is collected, washed with ethanol and water by centrifugation, and a one-dimensional Co-Asp nanowire structure product is obtained.

[0039] Step 3: Divide the Co-Asp nanowires obtained in step 2 into two parts, place them in a 50mL autoclave, add 20mL of absolute ethanol, 10mL of water and 160mg of nickel nitrate hexahydrate (limited to the reaction volume ...

Embodiment 2

[0043] Step 1: Weigh 0.20g of L-aspartic acid and 0.415g of cobalt nitrate in a 50mL autoclave, add 15mL of deionized water and 15mL of ethylene glycol, stir magnetically at room temperature for 30 minutes, and then continue to mix Add 3 mL of 2 mol / L sodium hydroxide solution dropwise into the solution until the solution turns a transparent brownish-red color and the pH is 6.7. After continuing magnetic stirring at room temperature for 1 hour, it is sealed and placed in an oven at 160°C for 10 hours.

[0044] Step 2: After the temperature of the autoclave in step 1 is cooled, the supernatant is poured off, the pink precipitate is collected, washed with ethanol and water by centrifugation, and a one-dimensional Co-Asp nanowire structure product is obtained.

[0045] Step 3: Put the Co-Asp nanowires obtained in Step 2 into a 50mL autoclave, add 20mL of absolute ethanol, 10mL of water and 160mg of nickel nitrate hexahydrate, stir magnetically at room temperature for 1 hour, and s...

Embodiment 3

[0049] Step 1: Weigh 0.40g of L-aspartic acid and 0.83g of cobalt nitrate in a 50mL autoclave, add 15mL of deionized water and 15mL of ethylene glycol, stir magnetically at room temperature for 30 minutes, and then continue to mix Add 3 mL of 2 mol / L sodium hydroxide solution dropwise into the solution until the solution turns a transparent brownish-red color with a pH of 6.2, continue magnetic stirring at room temperature for 1 hour, and then seal it and place it in an oven at 200°C for 5 hours.

[0050] Step 2: After the temperature of the autoclave in step 1 is cooled, the supernatant is poured off, the pink precipitate is collected, washed with ethanol and water by centrifugation, and a one-dimensional Co-Asp nanowire structure product is obtained.

[0051] Step 3: Divide the Co-based nanowires obtained in step 2 into two parts, place them in a 50mL autoclave, add 20mL of absolute ethanol, 10mL of water and 160mg of nickel nitrate hexahydrate, and stir magnetically at room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com