TiO2 photocatalyst and preparation method thereof

A photocatalyst and catalyst technology, applied in the field of photocatalytic materials, can solve the problems of affecting catalytic activity and stability, affecting catalyst activity and stability, easy loss of titanium dioxide, etc., to achieve good adsorption and desorption performance, good photocatalytic degradation performance, The effect of high photocatalytic reactivity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] (2) TiO 2 Preparation method of photocatalyst

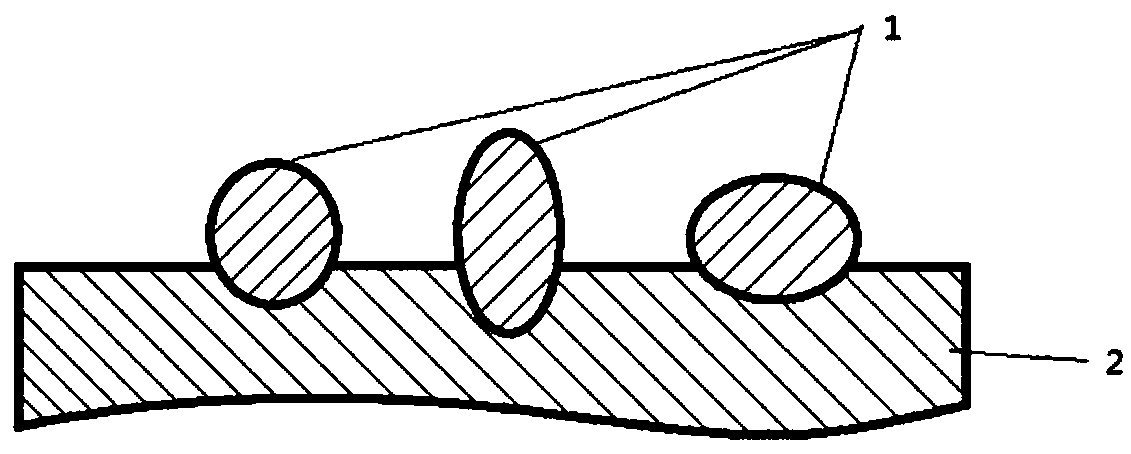

[0069] The second aspect of the present invention provides a foamed alumina-based carrier loaded with TiO 2 The preparation method of photocatalyst comprises:

[0070] (1) Preparation of titanium sol;

[0071] (2) Immerse the organic foam in the alumina-based slurry to hang the slurry, remove the excess slurry, and dry it.

[0072] (3) repeat step (2) process 0~5 times, preferably 1~4 times,

[0073] (4) Spray and immerse the mixed slurry of titanium oxide and aluminum oxide on the material obtained in step (3), and then dry and roast to obtain a foamed aluminum oxide-based carrier;

[0074](5) Immerse the foamed alumina-based carrier obtained in step (4) into the titanium sol obtained in step (1) for slurrying, remove excess slurry, and dry,

[0075] (6) Repeat the dipping process 0 to 5 times, preferably 1 to 4 times;

[0076] (7) The material obtained in step (6) is subjected to heat treatment to obtain foamed alu...

Embodiment 1

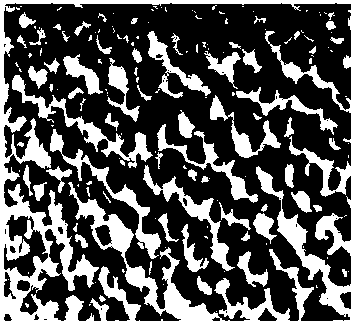

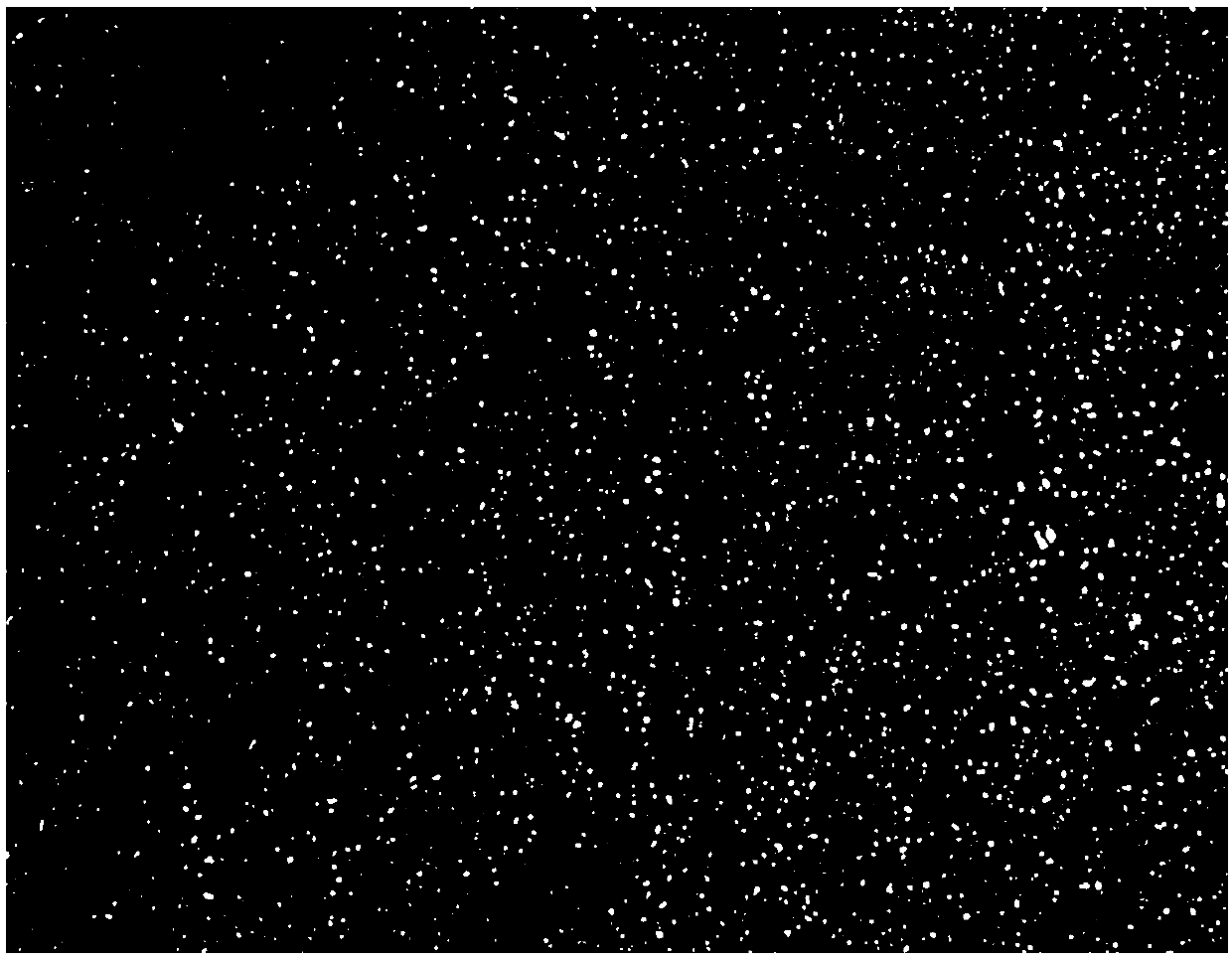

[0119] γ-Al 2 o 3 Powder, urea, aluminum hydroxide sol (calculated as alumina), kaolin, and water are mixed in a weight ratio of 10:0.3:2.0:0.3:6 to obtain an alumina-based slurry;

[0120] Nano-titanium oxide (below 100nm in particle size, the same below) is mixed with polyethylene glycol (molecular weight is 600), and then mixed with pseudo-boehmite, nitric acid, water, nano-titanium oxide, pseudo-boehmite (with Aluminum oxide), nitric acid, and water are mixed in a weight ratio of 15:3:2:15, and the amount of polyethylene glycol is added according to 3% of the weight of the mixed slurry of titanium oxide and aluminum oxide to obtain a mixture of titanium oxide and aluminum oxide. slurry;

[0121] Use polyurethane foam with a square plate for pretreatment, immerse the pretreated polyurethane foam in alumina-based slurry for vacuum dipping, remove excess slurry, dry at 75°C for 6 hours, repeat this process twice; then spray dip The mixed slurry of titanium oxide and alumin...

Embodiment 2

[0127] γ-Al 2 o 3 Powder, urea, aluminum hydroxide sol (calculated as alumina), kaolin, and water are mixed in a weight ratio of 10:0.4:2.0:0.4:7 to obtain an alumina-based slurry;

[0128] Nano-titanium oxide is mixed with polyethylene glycol (molecular weight: 600), and then mixed with pseudo-boehmite, nitric acid, and water, and nano-titanium oxide, pseudo-boehmite (calculated as alumina), nitric acid, and water are mixed The weight ratio is 15:3.5:2:18, the amount of polyethylene glycol added is 2.5% of the weight of the mixed slurry of titanium oxide and aluminum oxide, and the mixed slurry of titanium oxide and aluminum oxide is obtained;

[0129] Use polyurethane foam with a square plate for pretreatment, immerse the pretreated polyurethane foam in alumina-based slurry for vacuum dipping, remove excess slurry, dry at 75°C for 6 hours, repeat this process twice; then spray dip The mixed slurry of titanium oxide and aluminum oxide is subjected to unsaturated spray dippi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Pore density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com