Method for preparing nano cuprous oxide powder based on ion exchange process

A technology of nano-cuprous oxide and ion exchange, which is applied in the field of chemical industry and nano-functional materials, can solve the problems of high preparation process requirements and easy agglomeration of cuprous oxide powder, and achieve wide source of raw materials, good photocatalytic degradation performance, reaction The effect of low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

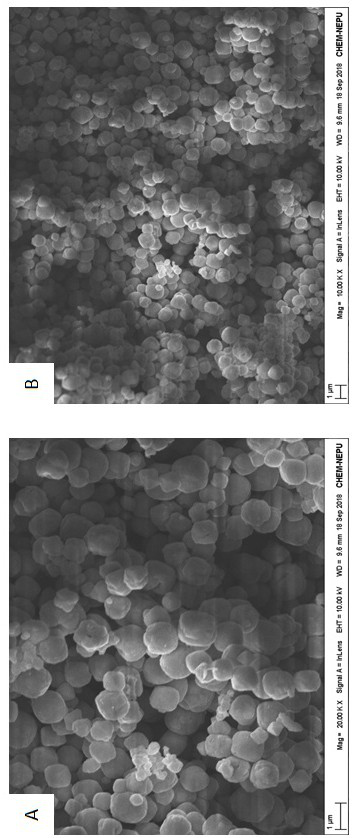

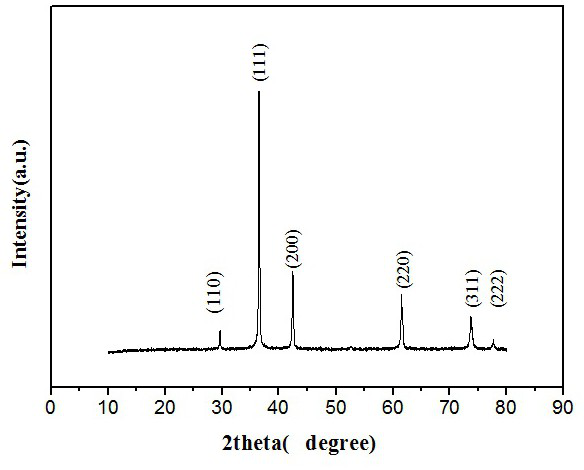

[0023] Take 100 mL of copper chloride solution with a concentration of 0.25 mol / L and react with 200 mL of cation exchange resin in a pneumatic stirring device for 1 hour to obtain copper hydroxide gel. Transfer it to another reactor, add glucose, the molar ratio of glucose and copper ions is added at 1:2, the reaction temperature is controlled at 70°C, the pH of the system is adjusted to 10 with sodium hydroxide, and the reaction is carried out for 1h. The cuprous precipitate was suction-filtered, washed three times with absolute ethanol, and vacuum-dried at 30°C for 20 hours to obtain nano-cuprous oxide powder. Pneumatic stirring device see figure 1 , the pneumatic stirring device includes a vacuum pump 1, a buffer bottle 2, an ion exchange column 3, and an open container. In the present embodiment, the open container is a beaker 4, and the ion exchange column 3 is fixed directly above the beaker 4 by an iron stand 5, and the ion exchange The air tube at the bottom of the c...

Embodiment 2

[0025] Take 100 mL of copper sulfate solution with a concentration of 0.5 mol / L and react with 200 mL of cation exchange resin in a pneumatic stirring device for 2 hours to obtain copper hydroxide gel. And transfer it to the reactor, add glucose, the molar ratio of glucose copper ion is added at 1:2.5, the reaction temperature is controlled at 75°C, the pH of the system is adjusted to 11 with sodium hydroxide, and the reaction is 1.5h, and the obtained oxynitride The copper precipitate was suction-filtered, washed three times with absolute ethanol, and vacuum-dried at 40° C. for 15 hours to obtain nano-cuprous oxide powder.

Embodiment 3

[0027] Take 200mL copper nitrate solution with a concentration of 1mol / L and react with 300mL cation exchange resin in a pneumatic stirring device for 1.5h to obtain copper hydroxide gel. And transfer it to the reactor, add glucose, glucose copper ion molar ratio is added at 1:3, the reaction temperature is controlled at 80 ° C, the pH of the system is adjusted to 10 with sodium hydroxide, the reaction is 2h, and the obtained cuprous oxide The precipitate was suction-filtered, washed three times with absolute ethanol, and vacuum-dried at 50° C. for 15 hours to obtain nano-cuprous oxide powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com