C3N4-BiVO4 catalyst with visible-light catalytic activity and preparation method thereof

A C3N4, composite catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of complicated composite methods, less research on composite reaction conditions, and long time consumption. Efficient photocatalytic degradation performance, easy mass synthesis, low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] C 3 N 4 -BiVO 4 The preparation process of photocatalytic materials is as follows:

[0027] 1) get a certain amount of analytically pure dicyandiamide (C 2 h 4 N 4) into a 50mL ceramic crucible, cover it, roast at 520°C for 2h, grind, and dissolve 1g in distilled water with ultrasonic stirring to obtain C 3 N 4 suspension;

[0028] 2) Weigh Bi(NO 3 ) 3 ·5H 2 O, NH 4 VO 3 and cetyltrimethylammonium bromide (CTAB), the weighed Bi(NO 3 ) 3 ·5H 2 O and NH 4 VO 3 respectively dissolved in 10.0mL 2.0mol / L HNO 3 and 10.0mL2.0mol / L NaOH solution, magnetically stirred at room temperature for 1h to obtain BiVO 4 Dispersions;

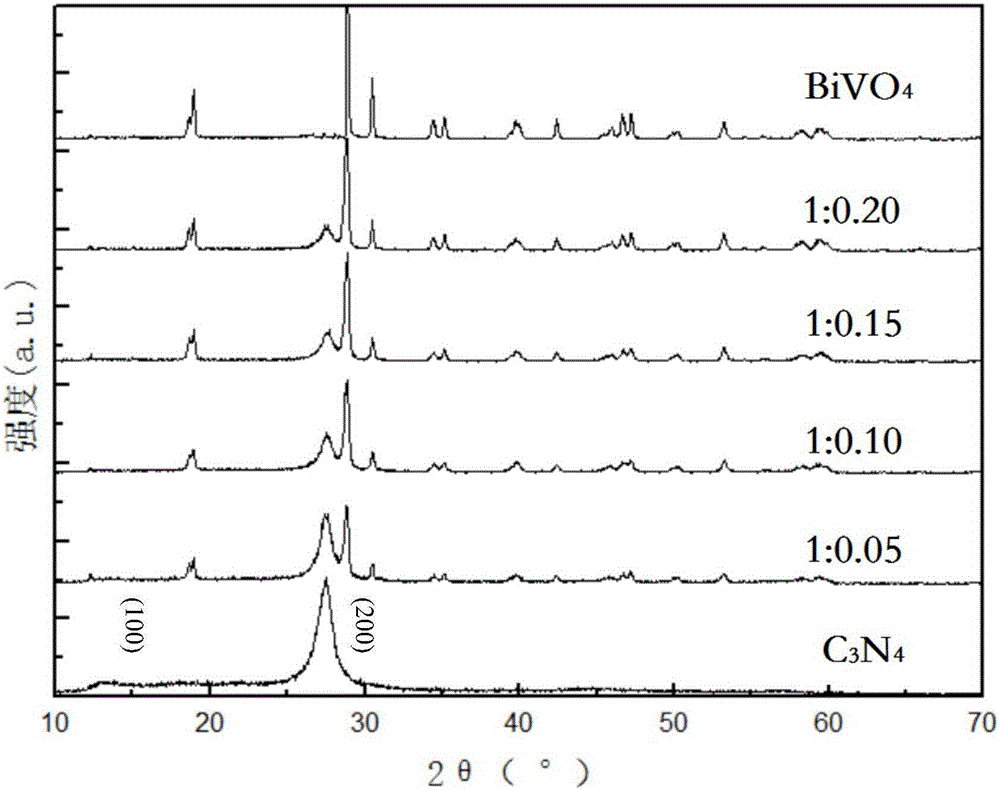

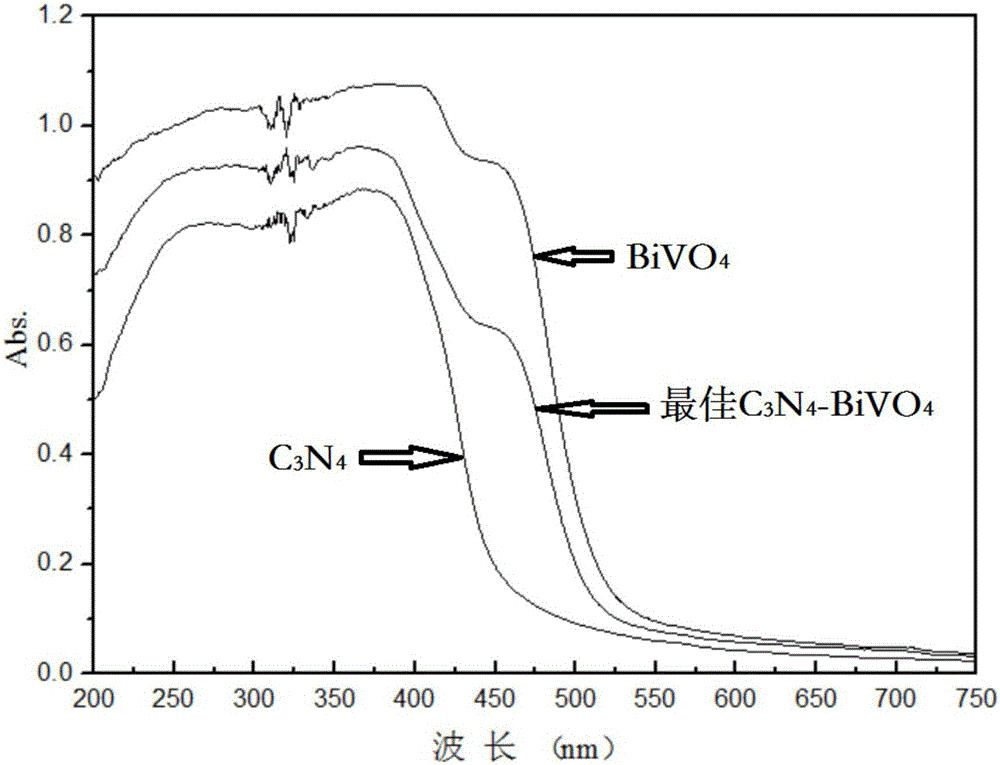

[0029] 3) C configured in step 1 3 N 4 Add the suspension and the CTAB weighed in step 2 to the BiVO configured in step 2 4 In the dispersion liquid, ultrasonically disperse for 30 minutes to obtain the precursor liquid, in which BiVO 4 and C 3 N 4 The mass ratio is 1:5—1:20 (the specific mass ratios are 1:5, 1:6.7, 1:10, 1:20);

...

Embodiment 2

[0039] In order to test the pH value of the precursor solution to C 3 N 4 -BiVO 4 The influence of visible light activity, in addition to the pH value of the precursor solution, other reaction conditions such as hydrothermal temperature of 180 ℃, hydrothermal time of 6h, BiVO 4 with C 3 N 4 The mass ratio of 1:6.7, 80 ℃ of drying temperature etc. are all identical with embodiment 1. The results show that when the pH value of the current flood solution is 6.00, C 3 N 4 -BiVO 4 The total decolorization rate of methyl orange is the highest, the catalyst prepared under the neutral pH of the precursor solution is 7.00, the decolorization effect is second, and the decolorization effect is poor under the condition of the precursor solution pH of 8.00. When the pH of the precursor solution is 6.00, C 3 N 4 -BiVO 4 The total decolorization rate of methyl orange is 98.14%; when the pH of the precursor solution is 7.00, C 3 N 4 -BiVO 4 The total decolorization rate of methyl...

Embodiment 3

[0041] To examine the effect of hydrothermal temperature on C 3 N 4 -BiVO 4 The influence of visible light activity, in addition to the hydrothermal temperature, other reaction conditions such as the pH of the precursor solution is 6.00, the hydrothermal time is 6h, BiVO 4 with C 3 N 4 The mass ratio of 1:6.7, 80 ℃ of drying temperature etc. are all identical with embodiment 1. The results showed that the decolorization rate of methyl orange was the highest when the hydrothermal temperature was 180°C. When the hydrothermal temperature is 180°C, C 3 N 4 -BiVO 4 The total decolorization rate of methyl orange is 98.14%; when the hydrothermal temperature is 200°C, C 3 N 4 -BiVO 4 The total decolorization rate of methyl orange is 94.81%; when the hydrothermal temperature is 120°C, C 3 N 4 -BiVO 4 The total decolorization rate of methyl orange is 87.79%; when the hydrothermal temperature is 150°C, C 3 N 4 -BiVO 4 The total decolorization rate of methyl orange is 85.9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com