Transparent COF design method

A design method and transparent technology, applied in the field of COF, can solve problems such as poor line detection, inability to see COF lines, and affect product quality, and achieve the effects of improving product quality, high flexibility, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

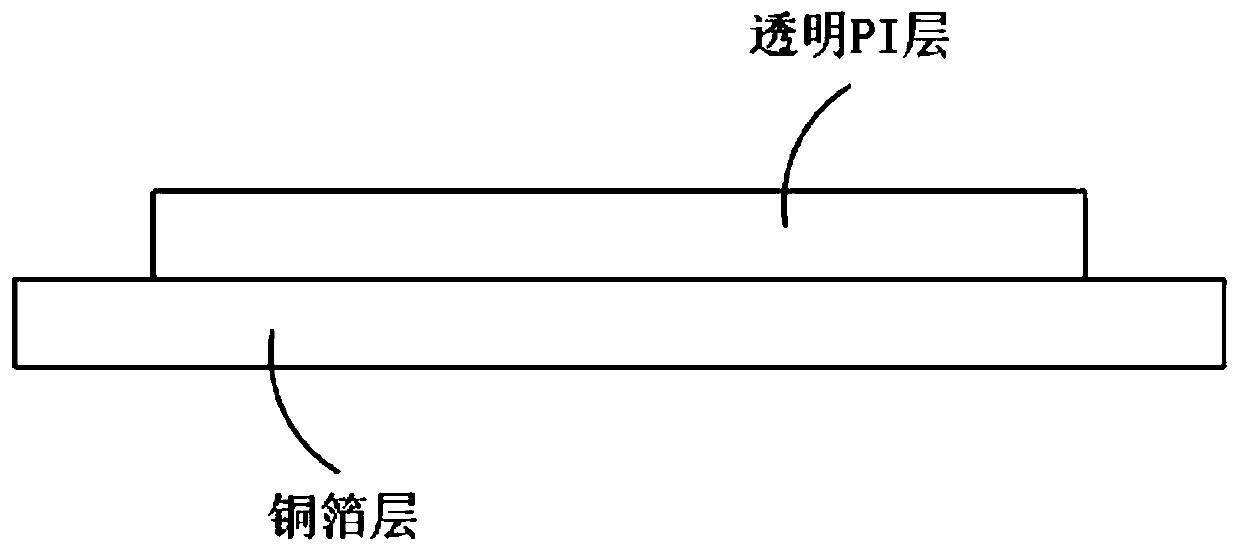

[0021] Such as figure 1 As shown, the embodiment of the present invention provides a transparent COF design method, the transparent COF is composed of a transparent PI layer and a copper foil layer;

[0022] The transparent COF includes the following preparation steps:

[0023] S1. Prepare a transparent PI layer, check the used transparent PI layer, and confirm that the transparent PI layer is not damaged, and the thickness of the transparent PI layer is 5 μm to 100 μm;

[0024] S2. Form the main copper foil layer on one side of the transparent PI layer by electroless copper plating, the thickness of the copper foil layer is 3 μm to 30 μm, and the transparent COF can be obtained;

[0025] S3. Detecting the prepared transparent COF to determine whether various properties of the transparent COF are qualified.

[0026] By using the transparent COF composed of transparent PI layer and copper foil layer, the internal circuit status can be clearly seen, which improves the accuracy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com