Cooler with variable cooling efficiency

A technology of cooling efficiency and coolers, applied in the direction of machines/engines, exhaust gas recirculation, mechanical equipment, etc., can solve the problems of increasing production costs and waste of coolers, and achieve the effect of reducing waste, reducing waste, and convenient replacement of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in combination with specific embodiments.

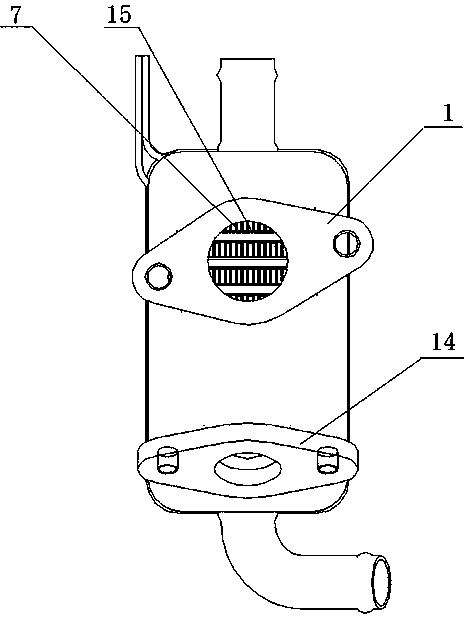

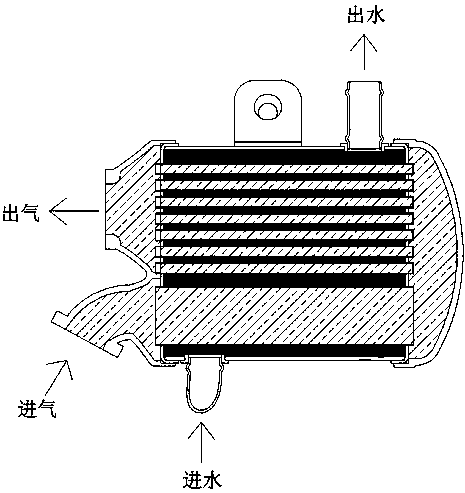

[0024] A variable cooling efficiency cooler that combines Figure 1 to Figure 5 As shown, it includes a housing 9, a flange-shaped cover plate 6, an air inlet pipe 12, an air outlet pipe 13, a fixed plate 2, a water inlet pipe 11, an outlet pipe 4, a preliminary cooling structure and a secondary cooling structure.

[0025] A flange-shaped cover plate 6 is provided on the right end of the housing 9 .

[0026] The inlet pipe 12 and the outlet pipe 13 are arranged at the left end of the housing 9 and are not connected to each other. The inlet pipe 12 is used to pass through the exhaust gas to be cooled, and the outlet pipe 13 is used to output the cooled exhaust gas. The air inlet pipe 12 and the air outlet pipe 13 provided can ensure the circulation of exhaust gas.

[0027] An air inlet flange 14 is arranged at the end of the air inlet pipe 12 , and an air outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com