Anaerobic fermentation system based on synergistic gas spray pipe

An anaerobic fermentation tank and gas technology, which is applied in the field of solid waste disposal and resource utilization in environmental engineering, can solve problems such as unfavorable stable operation and commissioning and start-up, reduce the effective volume of the tank, prolong the maintenance time of tank cleaning, etc., and achieve easy automation The effect of control, high energy utilization rate, and less labor requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

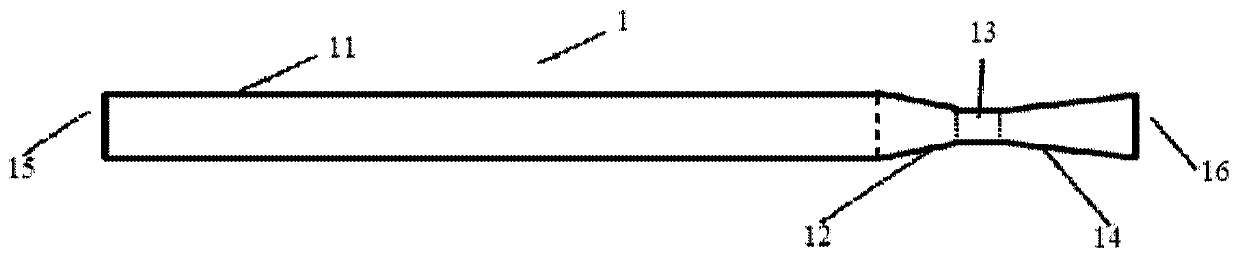

[0035] In a first exemplary embodiment of the present invention there is provided a booster gas nozzle such as figure 1 As shown, the synergistic gas nozzle 1 includes a main pipe section 11, a diameter reducing section 12, a throat section 13 and an expanding section 14 connected in sequence, wherein,

[0036] The main pipe section 11, the free end of the main pipe section 11 is set as an air inlet 15;

[0037] Reduced diameter section 12, the two ends of the reduced diameter section 12 are respectively connected with the main pipe section 11 and the throat section 13, the inner diameter of the reduced diameter section 12 gradually decreases from the main pipe section 11 to the throat section 13, and is used to accelerate the transported gas ;

[0038] A throat section 13, the two ends of the throat section 13 are respectively connected to the diameter-reducing section 12 and the expanding section 14;

[0039] An expansion section 14, the free end of the expansion section 1...

Embodiment 2

[0052] In the second exemplary embodiment of the present invention, as an aspect of the present invention, an anaerobic fermentation tank is also provided, and the anaerobic fermentation tank includes:

[0053] tank;

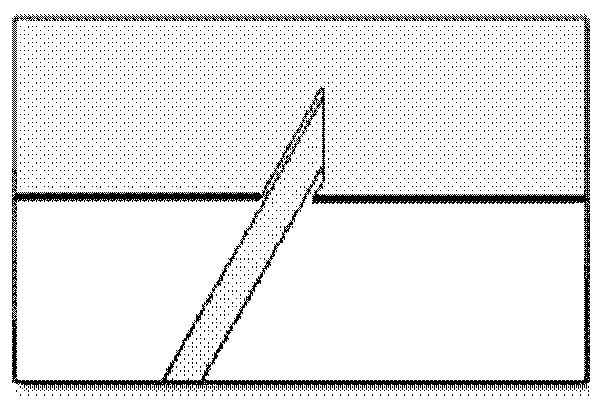

[0054] Like the synergistic gas nozzle 1 mentioned above, the end of the gas outlet 16 of the synergistic gas nozzle 1 is flush with the bottom of the tank; and the synergistic gas nozzle 1 is arranged at an angle with the horizontal plane.

[0055] More specifically, in order to make the efficient implementation of the gas stirring of the present invention, as Figure 3D As shown, the synergistic gas nozzle 1 needs to be assembled with the anaerobic fermentation tank, the synergistic gas nozzle 1 is connected to the bottom of the anaerobic fermentation tank, the upper part of the synergistic gas nozzle 1 is embedded in the bottom of the fermenter, and the synergistic gas nozzle The air outlet 16 of 1 is flush with the inner surface of the bottom of the anaerob...

Embodiment 3

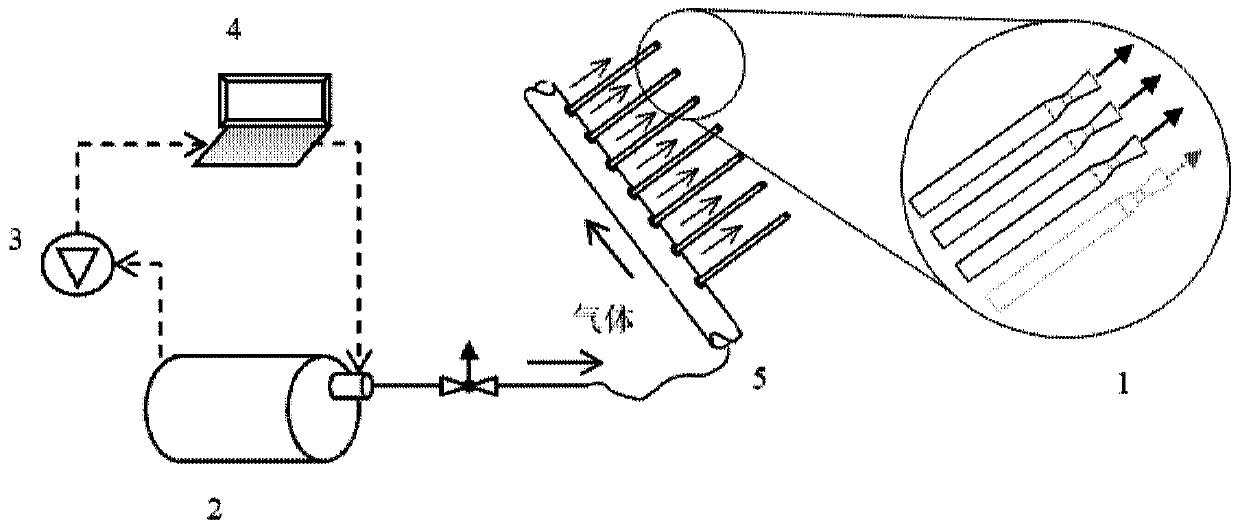

[0071] In a third exemplary embodiment of the present invention, an anaerobic fermentation system is also provided, such as figure 2 shown, including

[0072] As above-mentioned anaerobic fermenter, be used for carrying out anaerobic fermentation;

[0073] The pressure storage unit is used to store the pressure of the gas volume, store energy for the gas injection, and deliver the accelerated gas to the tank through the synergistic gas nozzle 1, so as to realize the material stirring in the tank;

[0074] The monitoring unit is used to measure the pressure value of the pressure reserve unit in real time;

[0075] The control unit is used for obtaining and analyzing the pressure value measured by the monitoring unit, and controlling the operation of the pressure reserve unit.

[0076] In an embodiment of the present invention, the pressure reserve unit includes:

[0077] Gas pressure storage tank 2, used to store compressed gas;

[0078] Large-resistance gas distribution p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com