Water-in-oil phase inversion emulsion spray and preparation method thereof

A technology of water-in-oil and emulsion, which is applied in the direction of pharmaceutical formulations, toiletry preparations, cosmetic preparations, etc. It can solve the problems of thick skin feeling, aggravated skin dryness, and low content of inorganic electrolytes in the internal phase, so as to prevent coalescence And thicken the creamy texture, improve the waterproof and sweatproof performance, and the effect of small dispersion and distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

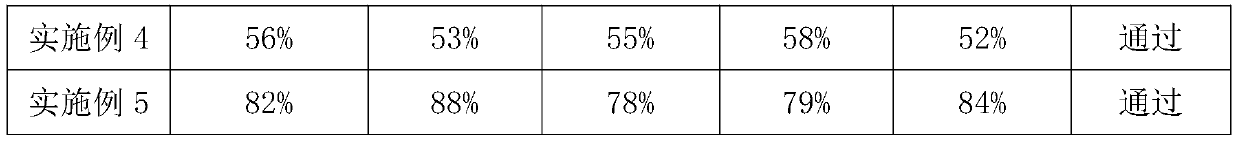

Embodiment 1

[0031]Another water-in-oil phase inversion emulsion spray provided by the invention contains the following components in parts by weight per 100g: 1.5g of sorbitan isostearate, 0.6g of polyglyceryl-3 diisostearate, cetyl Steareth-202.5g, Isopropyl Myristate 5.0g, Petrolatum 0.8g, Dimethicone 2.0g, Tocopherol (Vitamin E) 0.15g, Preservative PE9010 0.4g, Glycerin 5.0g , 0.6g 1,2-hexanediol, 0.1g carbomer, 0.8g sodium magnesium lithium silicate, 1.0g stabilizer, 0.08g disodium EDTA, 0.4g arginine, 0.1g essence, 78.97 deionized water g.

[0032] Among them, the preservative PE9010 is a compound of phenoxyethanol and ethylhexylglycerin, and the stabilizer is composed of hydroxyethyl acrylate / sodium acryloyldimethyl taurate copolymer, isohexadecane, and polysorbate-60. The compound is composed according to the mass ratio of 38:25:5.

[0033] The preparation method of the water-in-oil phase-inversion emulsion spray described in this example comprises the following steps successivel...

Embodiment 2

[0041] Another water-in-oil phase inversion emulsion spray provided by the invention contains the following components in parts by weight per 100g: 1.8g of sorbitan isostearate, 0.8g of polyglyceryl-3 diisostearate, cetyl Steareth-202.0g, Isopropyl Myristate 6.0g, Petrolatum 1.0g, Dimethicone 1.5g, Tocopherol (Vitamin E) 0.2g, Preservative PE90 100.3g, Glycerin 6.0g , 1,2-hexanediol 0.7g, carbomer 0.05g, sodium magnesium lithium silicate 0.5g, stabilizer 0.8g, disodium EDTA 0.05g, arginine 0.2g, essence 0.15g, deionized water 77.95 g.

[0042] Among them, the preservative PE9010 is a compound of phenoxyethanol and ethylhexylglycerin, and the stabilizer is composed of hydroxyethyl acrylate / sodium acryloyldimethyl taurate copolymer, isohexadecane, polysorbate-60 The compound is composed according to the mass ratio of 38:25:5.

[0043] The preparation method of the water-in-oil phase-inversion emulsion spray described in this example comprises the following steps successively: ...

Embodiment 3

[0051] Another water-in-oil phase inversion emulsion spray provided by the invention contains the following components in parts by weight per 100g: 1.2g of sorbitan isostearate, 1.0g of polyglyceryl-3 diisostearate, cetyl Steareth-202.8g, Isopropyl Myristate 7.0g, Petrolatum 1.3g, Dimethicone 3.0g, Tocopherol (Vitamin E) 0.25g, Preservative PE90100.5g, Glycerin 7.0g , 1.0g 1,2-hexanediol, 0.12g carbomer, 1.0g sodium magnesium lithium silicate, 1.2g stabilizer, 0.08g disodium EDTA, 0.5g arginine, 0.2g essence, 71.4 deionized water g.

[0052] Among them, the preservative PE9010 is a compound of phenoxyethanol and ethylhexylglycerin, and the stabilizer is composed of hydroxyethyl acrylate / sodium acryloyldimethyl taurate copolymer, isohexadecane, polysorbate-60 The compound is composed according to the mass ratio of 38:25:5. .

[0053] The preparation method of the water-in-oil phase-inversion emulsion spray described in this example comprises the following steps successively:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com