Cerium-containing magnet with high coercivity and preparation method thereof

A technology of high coercive force and magnets, applied in the direction of magnetic objects, inductors/transformers/magnets, magnetic materials, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

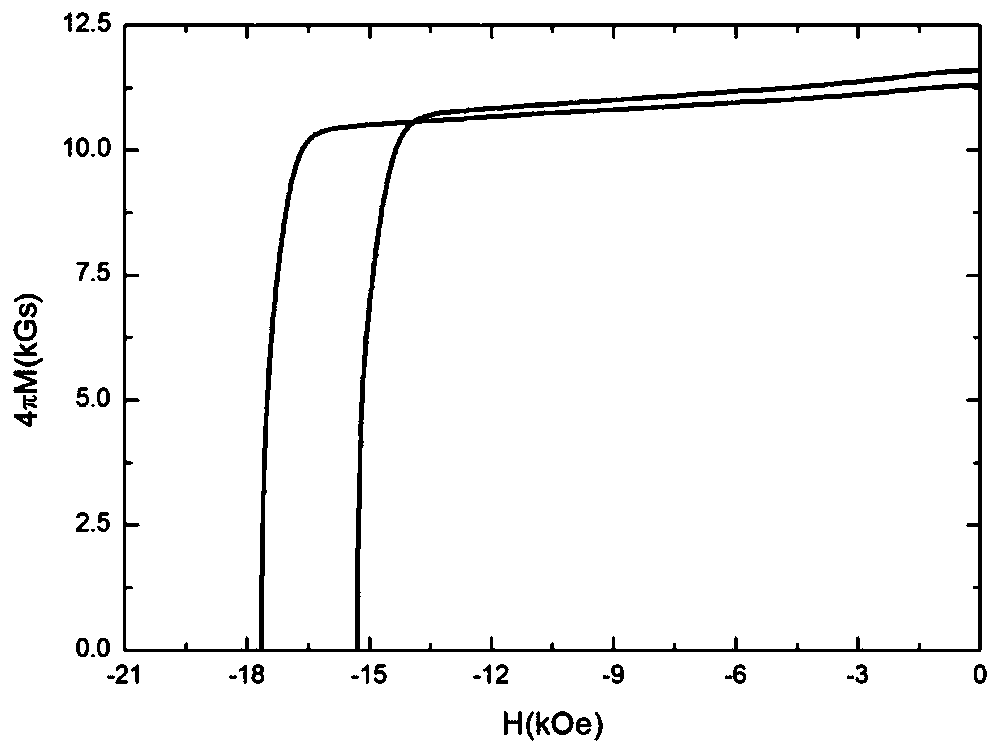

Image

Examples

Embodiment 1

[0037] 1) Proportioning various rare earth and transition metal raw materials into

[0038] The nominal composition of Pr4Nd16Ce8Ho3FebalCo1Zr0.1B1 is prepared by conventional vacuum smelting and quick-setting flake technology to prepare Ce-containing main alloy quick-setting flakes with a thickness of about 0.3mm;

[0039] 2) Proportioning Pr10Nd40Fe50 with praseodymium and neodymium metal and iron raw materials to form a nominal composition of Pr10Nd40Fe50, using a conventional quick-setting flake process to prepare a grain boundary optimized auxiliary alloy quick-setting sheet with a thickness of about 0.3 mm;

[0040] 3) Mix the quick-setting flakes of the main alloy containing Ce and the quick-setting flakes of the grain boundary optimized auxiliary alloy at a weight ratio of 1:0.06, and carry out hydrogen crushing and jet milling together to obtain a mixed powder with an average particle size of 2.8 μm; among them, hydrogen crushing The specific treatment is: under the h...

Embodiment 2

[0045] 1) Proportioning various rare earth and transition metal raw materials into

[0046] The nominal composition of Pr3Nd16Ce10Gd2FebalCo1Nb0.3B1 is prepared by conventional vacuum melting and quick-setting flake technology to prepare Ce-containing main alloy quick-setting flakes with a thickness of about 0.3mm;

[0047] 2) Proportion the raw materials into the nominal composition of Pr20Nd60Cu20, and prepare a grain boundary optimized auxiliary alloy quick-setting sheet with a thickness of about 0.3 mm by conventional quick-setting flake technology;

[0048] 3) Mix the Ce-containing main alloy quick-setting flakes and the grain boundary optimized auxiliary alloy quick-setting flakes at a weight ratio of 1:0.04, and perform hydrogen crushing and jet milling together to obtain a mixed powder with an average particle size of 2.6 μm; among them, hydrogen crushing The specific treatment is as follows: under the hydrogen pressure of 0.0.3Mpa, the mixed alloy quick-setting sheet ...

Embodiment 3

[0054] 1) Proportioning various rare earth and transition metal raw materials into

[0055] The nominal composition of Pr5Nd20Ce6Al0.2Cu0.2FebalCo1Nb0.2B1 is prepared by conventional vacuum melting and quick-setting flake technology to prepare Ce-containing main alloy quick-setting flakes with a thickness of about 0.3mm;

[0056] 2) Proportion the raw materials into the nominal composition of Ho56Fe14Cu30, and prepare a grain boundary optimized auxiliary alloy quick-setting sheet with a thickness of about 0.3 mm by using a conventional quick-setting flake process;

[0057] 3) Mix the Ce-containing main alloy quick-setting flakes and grain boundary optimized auxiliary alloy quick-setting flakes at a weight ratio of 1:0.08, and carry out hydrogen crushing and jet milling together to obtain a mixed powder with an average particle size of 3.0 μm; wherein, hydrogen crushing The specific treatment is: under the hydrogen pressure of 0.25Mpa, the mixed alloy quick-setting sheet absorb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com