Novel display panel surface defect detection system

A display panel and defect detection technology, which is applied in the directions of optical testing flaws/defects, measuring devices, optics, etc., can solve the problems of damage to the support structure of the pixel display area, complicated image processing process, scratches on the surface of the display panel, etc., to improve the equipment. The effect of the marriage rate, the simple image processing process, and the reduction of equipment maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

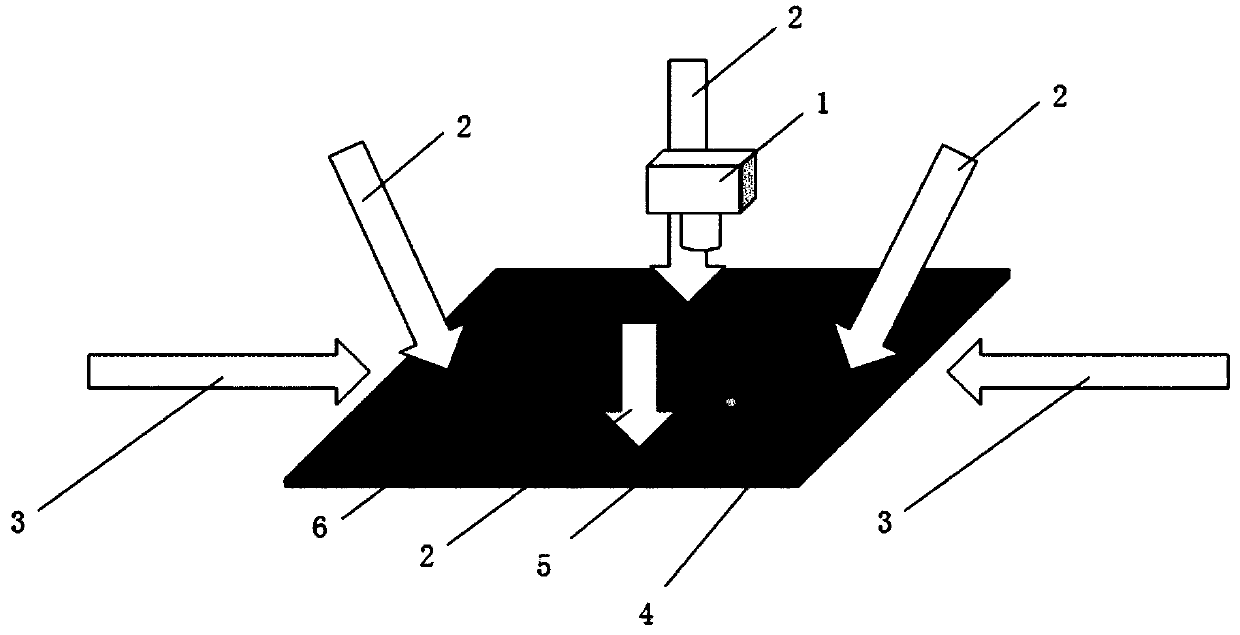

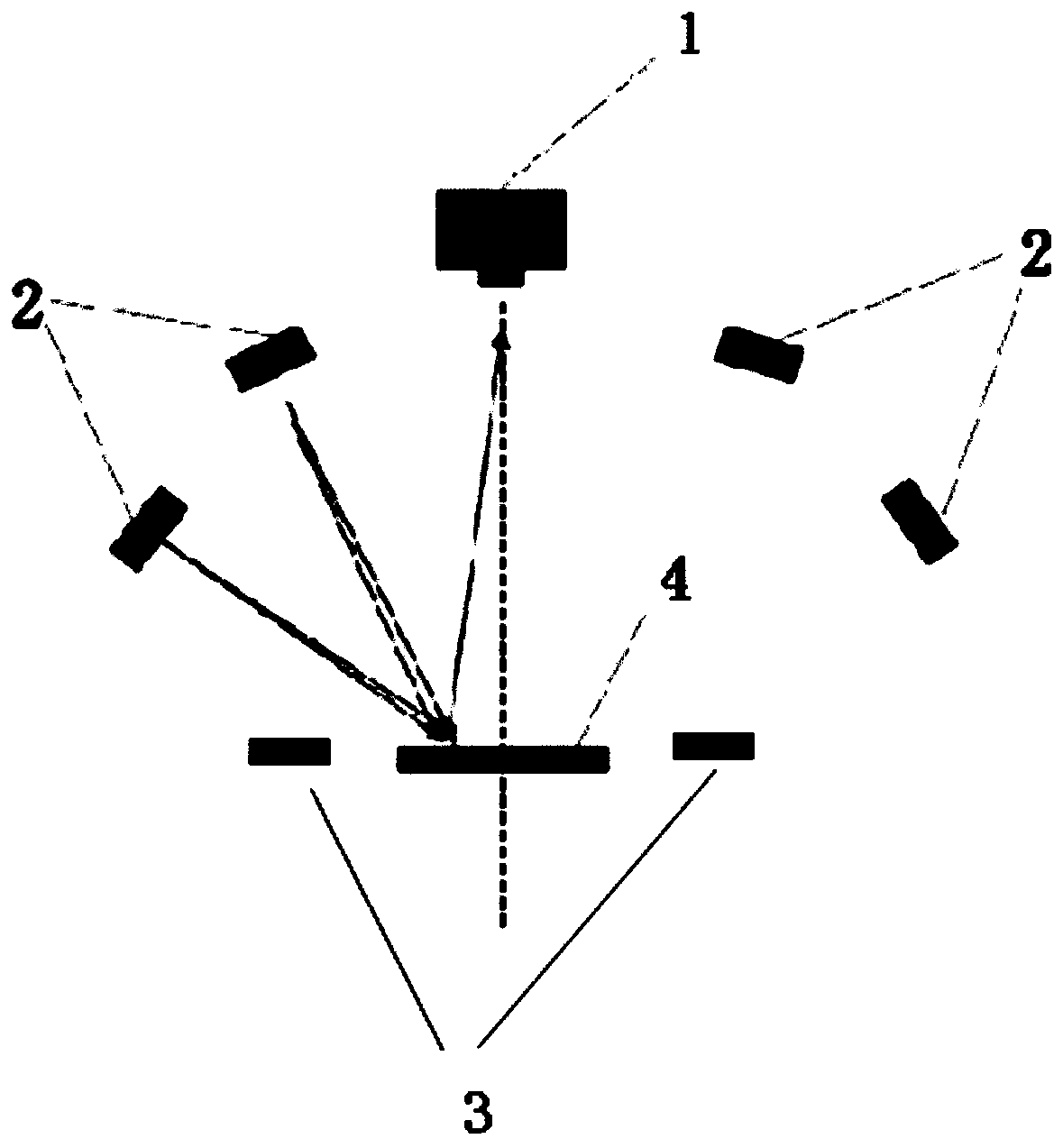

Embodiment 1

[0084] Turn on the main light source and the auxiliary light source to take pictures in time-sharing, that is: only the main optical unit is turned on, and when the auxiliary optical unit is not turned on, the image acquisition device collects the image of the detected display panel, which is recorded as the first original detection image; only the auxiliary optical unit is turned on , when the main optical unit is not turned on, the image acquisition device acquires the image of the detected display panel, which is recorded as the second original detection image; the image acquisition device uploads both the first original detection image and the second original detection image to the image processing unit;

[0085] The image processing unit compares and analyzes the first original detection image and the second original detection image, and based on the second original detection image, eliminates the erasable foreign matter on the surface from the first original detection imag...

Embodiment 2

[0087] Turn on the main light source and auxiliary light source at the same time, but choose different light source colors for the main light source and auxiliary light source. The preferred color combination of the main light source and the auxiliary light source may be the mode of "blue+red" or "red+blue". Then use the image acquisition device to collect the image of the detected display panel, which is recorded as the third original detection image; and upload the third original detection image to the image processing unit;

[0088] The image processing unit analyzes the third original detection image according to the color characteristics. Since the auxiliary light source can illuminate dust and other surface erasable foreign objects but cannot illuminate real bad defects, the main light source can illuminate real bad defects and surface erasable foreign objects. The foreign matter is illuminated at the same time. Therefore, the image processing unit can distinguish the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com