A wear-resistant bearing bush that is easy to locate and assemble

A bearing pad and lateral positioning technology, which is applied to the lubrication of shafts and bearings, bearing components, and engines, can solve the problems of user inconvenience, spreading, and cumbersome procedures, and achieve the effect of facilitating positioning and assembly and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

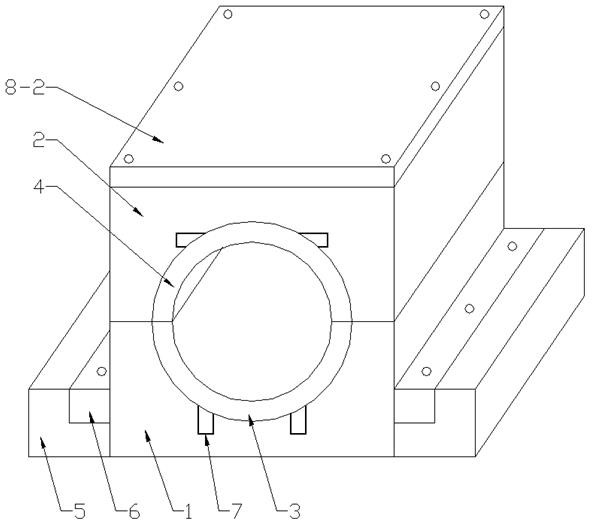

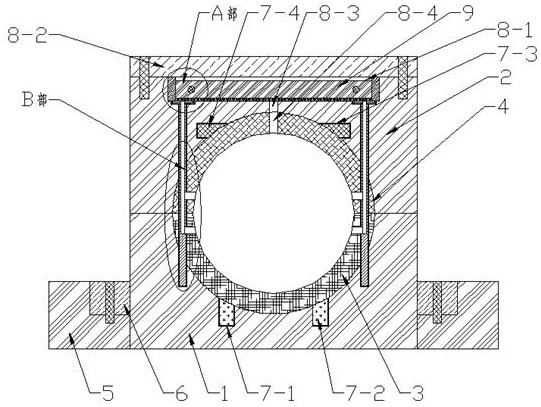

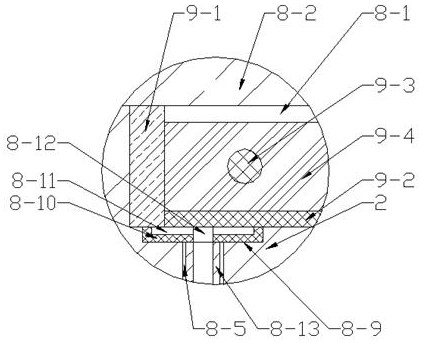

[0029] see e.g. Figure 1 to Figure 7 As shown, the technical solution adopted in this specific embodiment is: lower bearing seat 1, upper bearing seat 2, lower bearing shell 3, upper bearing shell 4, connecting plate 5, mounting seat 6, positioning mechanism 7, oiling mechanism 8 and oil-passing mechanism 9; an upper bearing seat 2 is arranged above the lower bearing seat 1; a lower bearing shell 3 is arranged in the lower bearing seat 1, and an upper bearing shell 4 is arranged in the upper bearing seat 2; the left and right sides of the lower bearing seat 1 are connected by bolts. The plate 5 and the connecting plate 5 are embedded in the mounting seat 6 and connected by bolts; when the bearing bush needs to be removed, directly remove the connecting plate 5 on the mounting seat 6 for use, without removing the mounting seat 6 at the corresponding position;

[0030]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com