Concrete anti-mud agent

An anti-mud agent and concrete technology, applied in the field of concrete anti-mud agent, can solve the problems of insufficient water reduction rate, large slump loss, decreased working performance, etc., and achieve the effect of reducing adsorption consumption and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

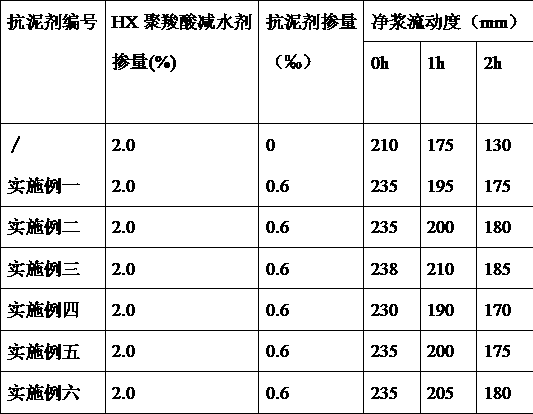

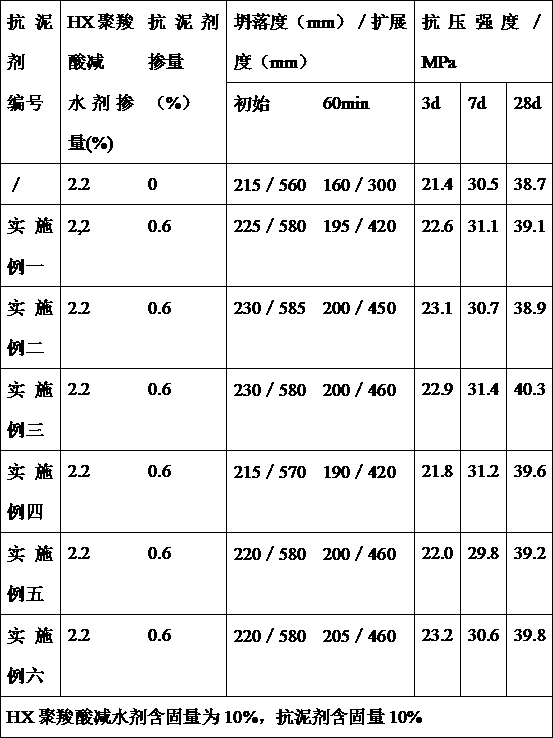

Examples

preparation example Construction

[0018] Its preparation method comprises the following steps:

[0019] Preparation of base material: Weigh 300 kg of deionized water and 83.1 kg of methacryloyloxyethyltrimethylammonium chloride (DMC), stir evenly, and prepare for polymerization.

[0020] Preparation of material A: Weigh 56 kg of maleic anhydride (MA) and 177.4 kg of 2-acrylamide-2-methylpropanesulfonic acid (AMPS) respectively, dissolve them in 300 kg of deionized water, and then add 144 kg of acrylic acid (AA), Stir well and prepare for dropwise addition.

[0021] Preparation of material B: Weigh 46 kg of ammonium persulfate, dissolve in 300 kg of deionized water, stir evenly, and prepare for dropwise addition.

[0022] Start the mixer, heat the bottom material to about 90°C, add 32.9 grams of sodium hypophosphite, and start adding materials A and B dropwise after ten minutes of stirring. The material A is added dropwise for 150±20 minutes, and the material B is added dropwise for 180±20 minutes. After the ...

Embodiment 2

[0024] The raw materials in this example include: 144 kg of acrylic acid (AA), 56 kg of maleic anhydride (MA), 177.4 kg of 2-acrylamide-2-methylpropanesulfonic acid (AMPS), methacryloyloxyethyl tris Methyl ammonium chloride (DMC) 103.8 kg, ammonium persulfate 48.1 kg, sodium hypophosphite 43.3 kg.

[0025] Its preparation method comprises the following steps:

[0026] Preparation of base material: Weigh 300 kg of deionized water and 103.8 kg of methacryloyloxyethyltrimethylammonium chloride (DMC), stir evenly, and prepare for polymerization.

[0027] Preparation of material A: Weigh 56 kg of maleic anhydride (MA) and 177.4 kg of 2-acrylamide-2-methylpropanesulfonic acid (AMPS) respectively, dissolve them in 300 kg of deionized water, and then add 144 kg of acrylic acid (AA), Stir well and prepare for dropwise addition.

[0028] Preparation of material B: Weigh 48.1 kg of ammonium persulfate, dissolve it in 300 kg of deionized water, stir evenly, and prepare for dropwise addi...

Embodiment 3

[0031] The raw materials in this example include: 144 kg of acrylic acid (AA), 56 kg of maleic anhydride (MA), 177.4 kg of 2-acrylamide-2-methylpropanesulfonic acid (AMPS), methacryloyloxyethyl tris Methyl ammonium chloride (DMC) 124.6 kg, ammonium persulfate 50.2 kg, sodium hypophosphite 45.2 kg.

[0032] Its preparation method comprises the following steps:

[0033] Preparation of base material: Weigh 300 kg of deionized water and 124.6 kg of methacryloyloxyethyltrimethylammonium chloride (DMC), stir evenly, and prepare for polymerization.

[0034] Preparation of material A: Weigh 56 kg of maleic anhydride (MA) and 177.4 kg of 2-acrylamide-2-methylpropanesulfonic acid (AMPS) respectively, dissolve them in 300 kg of deionized water, and then add 144 kg of acrylic acid (AA), Stir well and prepare for dropwise addition.

[0035] Preparation of material B: Weigh 50.2 kg of ammonium persulfate, dissolve it in 300 kg of deionized water, stir evenly, and prepare for dropwise addi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com