Ta-doped potassium sodium niobate-based piezoelectric ceramic material and preparation method thereof

A potassium niobate-based, piezoelectric ceramic technology, applied in the field of functional ceramic materials, can solve the problems of shortening the time, the effect is not particularly good, and there is no research on the density of ceramics, and achieves low reaction temperature, short time, and high heat energy utilization. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

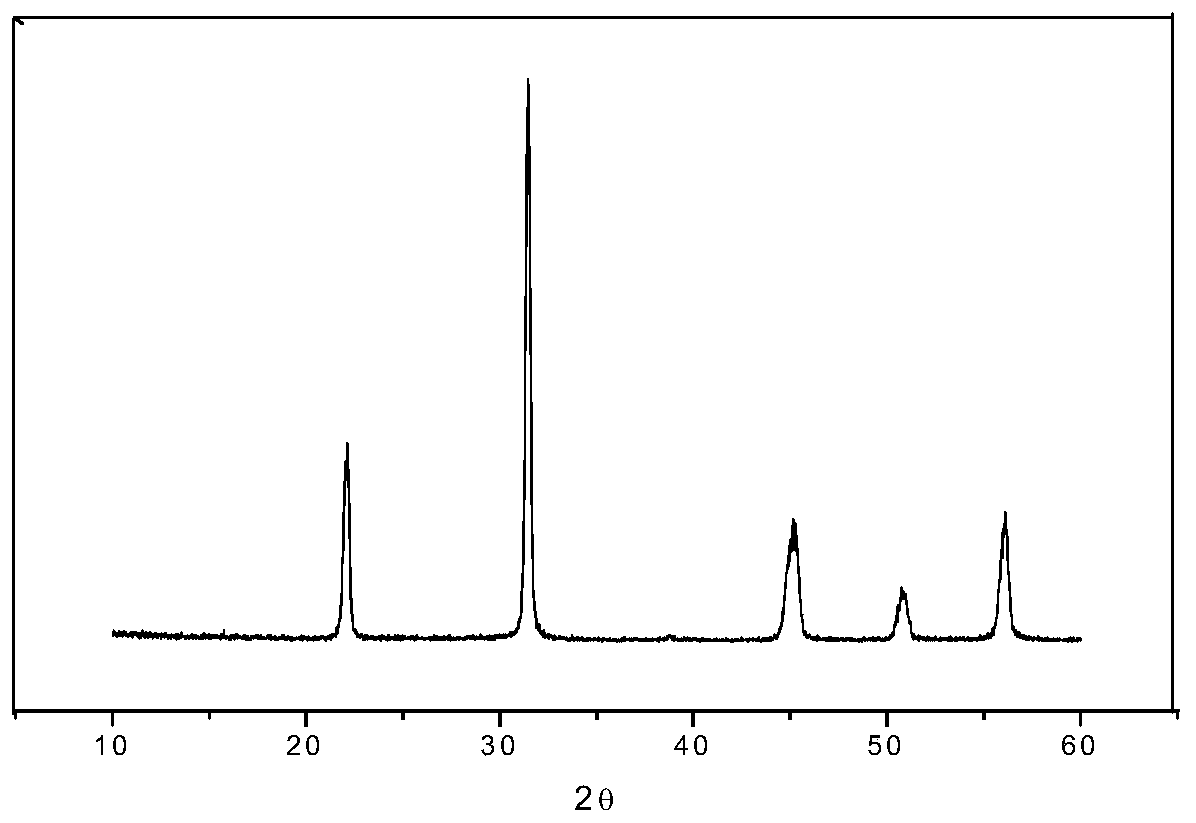

Embodiment 1

[0032] 1.Na 0.5 K 0.5 Nb 0.89 Ta 0.11 o 3 Powder preparation:

[0033] (1) Take solid KOH, NaOH and add water to configure the mixed lye with a concentration of 7mol / L, NaOH + and K + The ratios are 1:6, Nb 2 o 5 and Ta 2 o 5 The mass molar ratio of the added total amount and lye is 1:8, wherein Nb 2 o 5 and Ta 2 o 5 The mass molar ratio of the mixture is 8:1, and 1.5wt% of polyethylene glycol is added.

[0034] (2) Mix the powder with the lye and place it in a polytetrafluoroethylene-lined reaction kettle, put the reaction kettle into a microwave reactor, set the reaction temperature to 160°C, and the reaction time to 2h.

[0035] (3) Pour the supernatant of the lining into a beaker and add hydrochloric acid dropwise to neutrality, no precipitation is seen.

[0036] (4) Wash the white precipitate on the bottom of the inner substrate with deionized water until neutral, and dry it in an oven at 100° C. for 1 hour.

[0037] 2.Na 0.5 K 0.5 Nb 1-y Ta y o 3 Pie...

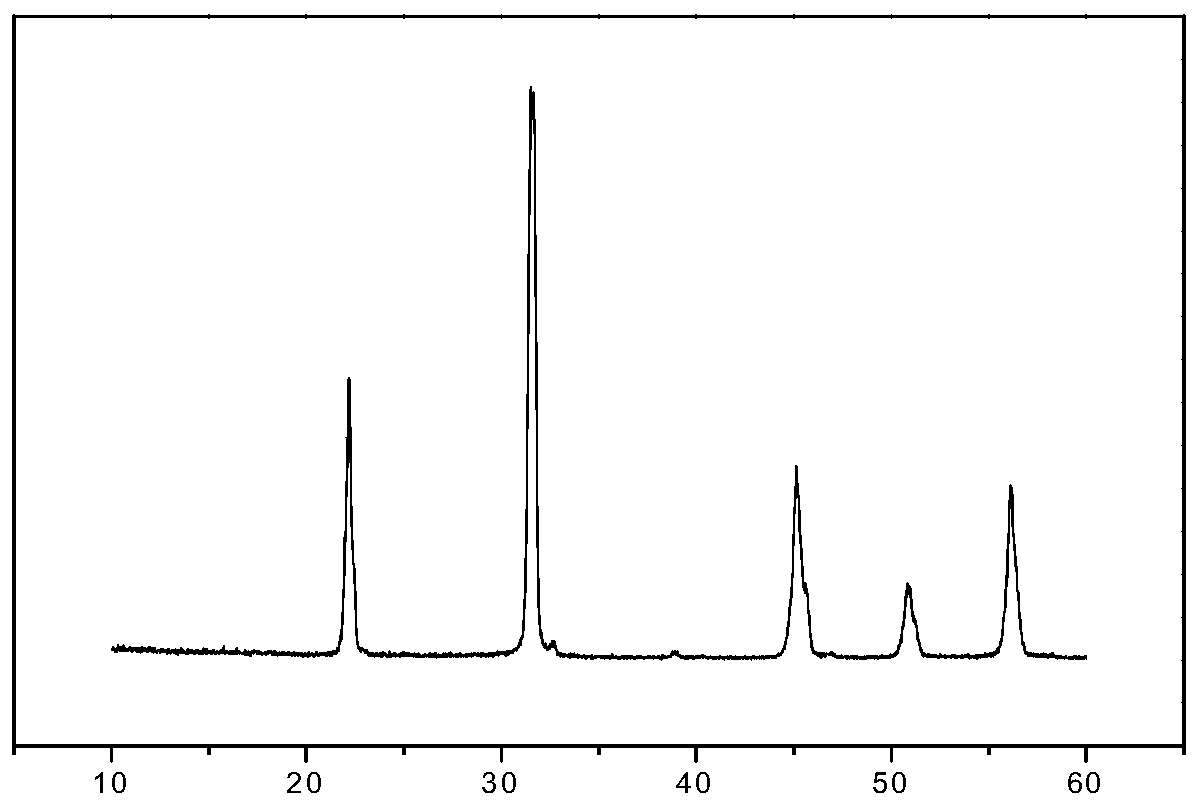

Embodiment 2

[0044] 1.Na 0.5 K 0.5 Nb 0.86 Ta 0.14 o 3 Powder preparation:

[0045] (1) Take solid KOH, NaOH and add water to configure the mixed lye with a concentration of 7mol / L, wherein NaOH + and K + The ratios are 1:6, Nb 2 o 5 and Ta 2 o 5 The mass molar ratio of the added total amount and lye is 1:8, wherein Nb 2 o 5 and Ta 2 o 5 The mass molar ratio is 6:1, and 1.5wt% polyacrylic acid is added.

[0046] (2) Mix the powder with the lye and place it in a polytetrafluoroethylene-lined reaction kettle, put the reaction kettle into a microwave reactor, set the reaction temperature to 170°C, and the reaction time to 3h.

[0047] (3) Pour the supernatant of the lining into a beaker and add hydrochloric acid dropwise to neutrality, no precipitation is seen.

[0048] (4) Wash the white precipitate on the bottom of the inner substrate with deionized water until neutral, and dry it in an oven at 100° C. for 1 hour.

[0049] 2.Na 0.5 K 0.5 Nb 1-y Ta y o 3 Piezoelectric ce...

Embodiment 3

[0056] 1.Na 0.5 K 0.5 Nb 0.83 Ta 0.17 o 3 Powder preparation:

[0057] (1) Take solid KOH, NaOH and add water to configure the mixed lye with a concentration of 7mol / L, wherein NaOH + and K + The ratios are 1:6, Nb 2 o 5 and Ta 2 o 5 The mass molar ratio of the added total amount and lye is 1:10, wherein Nb 2 o 5 and Ta 2 o 5 The mass molar ratio is 5:1, and 1.5wt% of polyacrylic acid is added.

[0058] (2) Mix the powder with the lye and place it in a polytetrafluoroethylene-lined reaction kettle, put the reaction kettle into a microwave reactor, set the reaction temperature to 180°C, and the reaction time to 3h.

[0059] (3) Pour the supernatant of the lining into a beaker and add hydrochloric acid dropwise to neutrality, no precipitation is seen.

[0060] (4) Wash the white precipitate on the bottom of the inner substrate with deionized water until neutral, and dry it in an oven at 100° C. for 1 hour.

[0061] 2.Na 0.5 K 0.5 Nb 1-y Ta y o 3 Piezoelectri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com