Ship type garbage processing device capable of processing water borne garbage

A waste treatment device and water treatment technology, which are applied in water/sewage treatment, oxidized water/sewage treatment, water/sewage treatment equipment, etc., can solve the loss of self-purification function of water body, active anaerobic bacteria, black and odorous water body, etc. problems, to achieve the effect of enhancing self-purification ability, meeting the needs of oxygen consumption, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

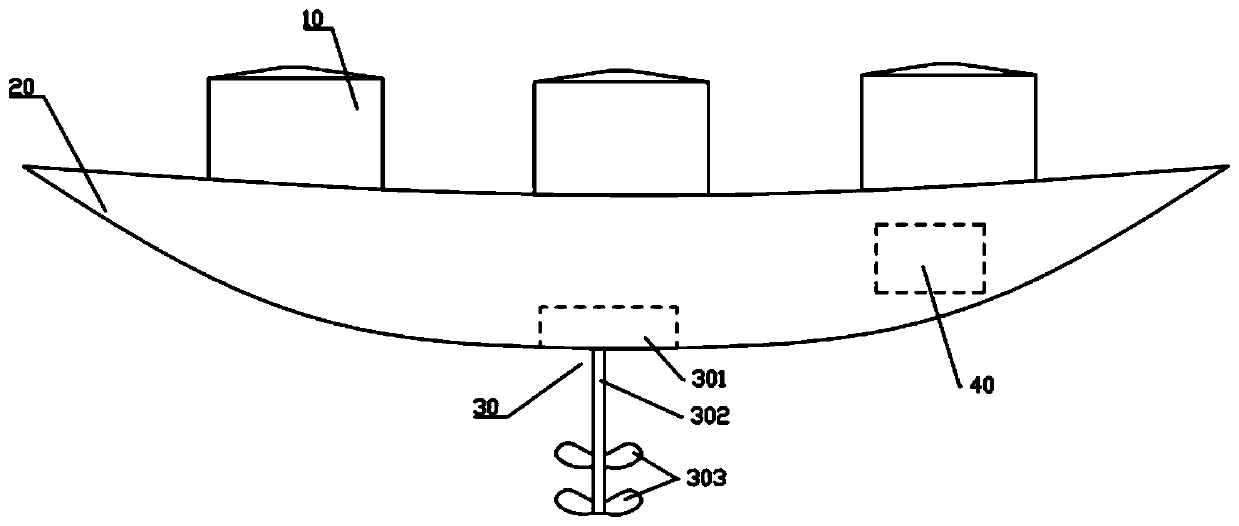

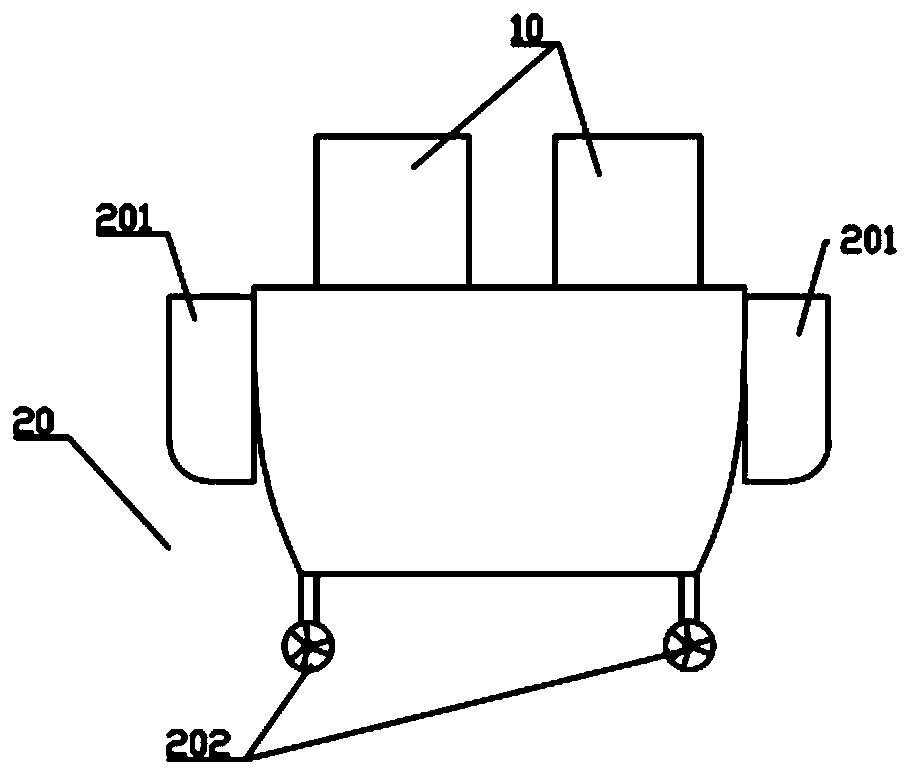

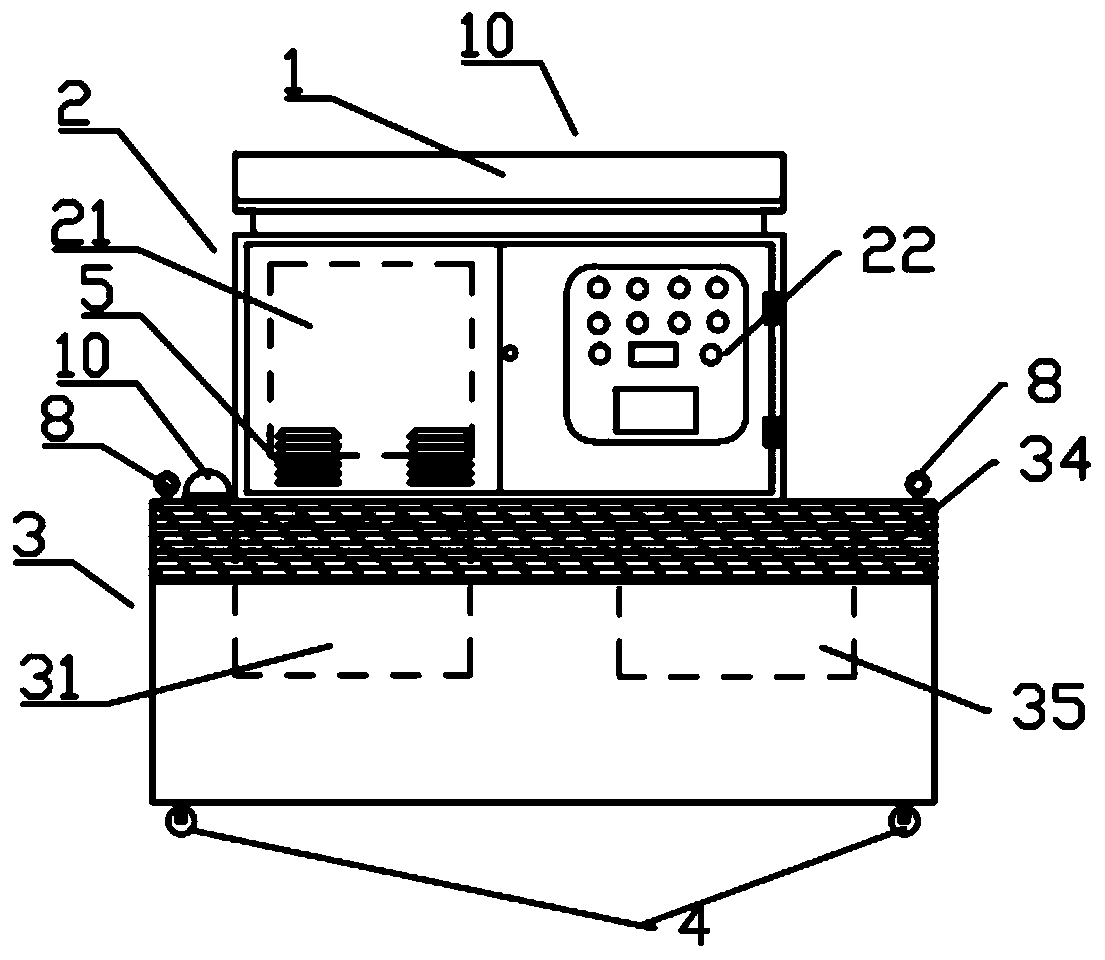

[0062] Such as Figure 1-4 The shown ship-type garbage treatment device capable of handling garbage on water includes a pollution control device 10, a pollution control hull 20, a stirring device 30 and a generator 40, and the pollution control ship 20 is respectively equipped with a pollution control device 10 and a stirring device 30 And generator 40, described pollution control device 10 comprises top cover 1, first working box 2 and second working box 3, described top cover 1 is arranged on the top of first working box 2, and described top cover 1 is located at On the top of the first working box 2, the top cover 1 is in the shape of a protrusion with a high middle and low sides, which is convenient for not accumulating liquid during use. Further, the first working box 2 is located on the top of the second working box 3, the first working box 2 includes an ozone generator 21 and an automatic control device 22, the automatic control device 22 is controlled by PLC, and the s...

Embodiment 2

[0064] Based on the structural foundation of embodiment 1, such as Image 6 , 7 Shown, in order to carry out better the integration of sewage and nano-bubbles, can be provided with water pump 36 on the second working box 3, described water pump 36 is provided with suction pipe 6, and suction pipe 6 is connected with nano-bubble device 35, pumps The water pipe 6 stretches out from the trapezoidal opening one 32 of the second working box 3 . During work, the ozone generator 21 and the oxygen generating device 31 produce pure oxygen and ozone, and after passing through the nano-bubble device 35, nano-pure oxygen bubbles or nano-ozone bubbles are formed, and the sewage sucked in by the suction pipe 6 forms a gas-water mixed liquid Flushing into sewage increases the solubility of air bubbles, and this solution can achieve a good degradation effect.

Embodiment 3

[0066] Based on the structural basis of embodiment 1, the bottom of the lower surface of the pollution control hull 20 is provided with an anti-corrosion coating, and the formula of the anti-corrosion coating is:

[0067] Neoprene 55-60 parts

[0068] Hydroxy acrylic resin 6-8 parts

[0069] Phenolic resin 7-10 parts

[0070] Bis-tri-n-butyltin oxide 12-14 parts

[0071] Titanium dioxide 10-12 parts

[0072] Rosin 8-11 parts

[0073] Diisobutyl phthalate 11-15 parts

[0074] Methyl isobutyl ketone 26-30 parts

[0075] Toluene 26-30 parts

[0076] Silane coupling agent 5-7 parts

[0078] Red lead 9-11 servings

[0079] Iron oxide 3-6 parts

[0080] Silica 11-14 parts

[0082] Anticorrosion agent 10-14 parts.

[0083] Wherein, the component of described anticorrosion agent is made up of following composition by weight percentage:

[0084] MBT 1.5-3.0 parts

[0085] Thiourea 1.2-1.5 parts

[0086] Rosin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com