A preparation method of highly breathable and antibacterial functional composite fabric

A composite fabric and functional technology, applied in the field of fabrics, can solve the problems of not being suitable for people with sensitive skin, breeding mites and bacteria, and prone to mildew in fibers, so as to avoid the passage of water droplets and macromolecules, with good effect and improved UV resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

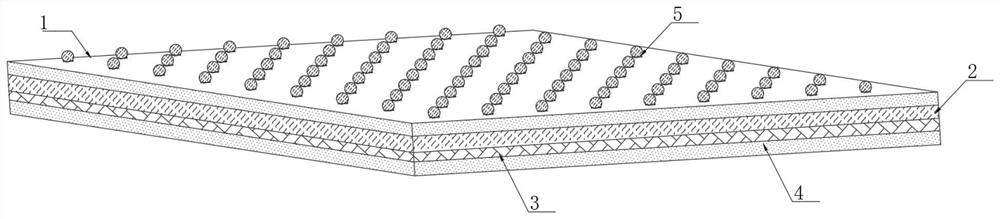

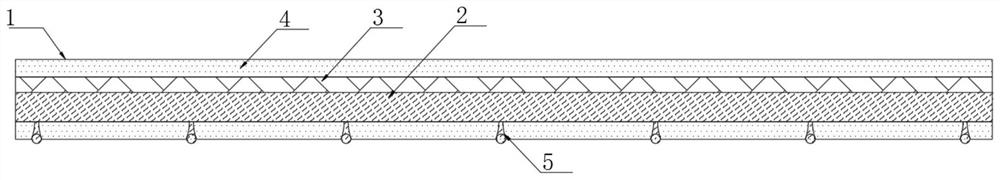

Image

Examples

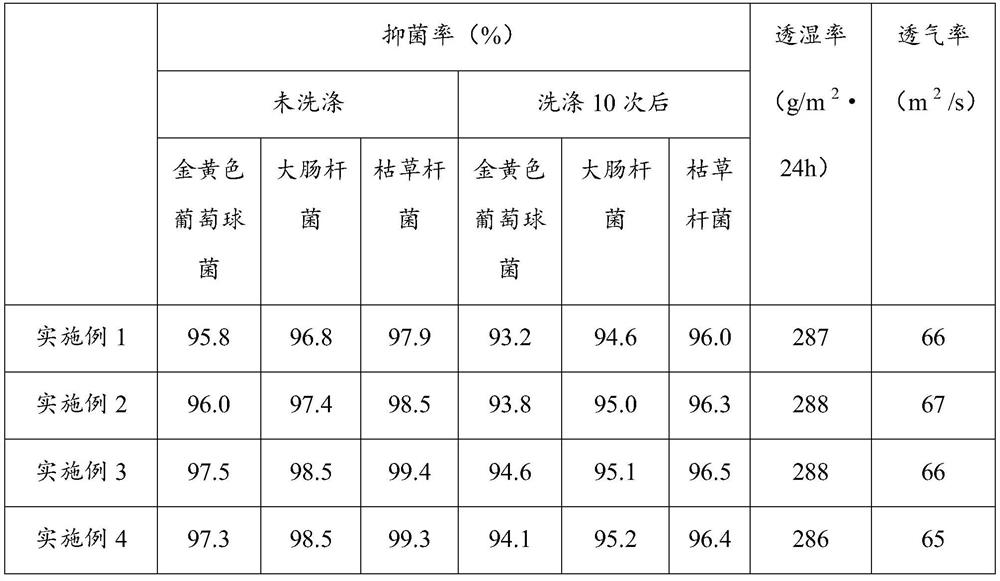

Embodiment 1

[0035] The main materials used in the functional coating layer include by weight: 65 parts of two-component water-based polyurethane, 23 parts of bamboo fiber nano-powder, 12 parts of silica nano-particles, 9 parts of tea tree essential oil, 8 parts of gypsum powder, and 8 parts of composite reinforcing glue 1 part, 3 parts of natural antibacterial factor complex, 1 part of oil-soluble benzotriazole, 2 parts of softener ES, 3 parts of polydimethylsiloxane and 1 part of fragrance agent. The preparation method of the composite fabric is as follows:

[0036] S1: Use lyocell fiber and modal fiber blend to make fabric base layer 2, use bamboo charcoal fiber and polyester fiber warp and weft to weave antibacterial fabric, and cut Gore-Tex fabric for spare;

[0037] S2: Prepare a functional coating layer, as follows:

[0038] S2.1: Dissolve oil-soluble benzotriazole in tea tree essential oil, and use compound reinforcing glue to encapsulate the natural antibacterial factor complex into...

Embodiment 2

[0050] The main materials used in the functional coating layer include by weight: 66 parts of two-component water-based polyurethane, 24 parts of bamboo fiber nano-powder, 13 parts of silica nano-particles, 10 parts of tea tree essential oil, 9 parts of gypsum powder, and 9 parts of composite reinforcing glue 4 parts, 4 parts of natural antibacterial factor complex, 2 parts of oil-soluble benzotriazole, 3 parts of softener ES, 4 parts of polydimethylsiloxane and 2 parts of fragrance, the preparation method of this composite fabric is as follows:

[0051] S1: Use lyocell fiber and modal fiber blend to make fabric base layer 2, use bamboo charcoal fiber and polyester fiber warp and weft to weave antibacterial fabric, and cut Gore-Tex fabric for spare;

[0052] S2: Prepare a functional coating layer, as follows:

[0053] S2.1: Dissolve oil-soluble benzotriazole in tea tree essential oil, and use compound reinforcing glue to encapsulate the natural antibacterial factor complex int...

Embodiment 3

[0065] The main materials used in the functional coating layer include by weight: 67 parts of two-component water-based polyurethane, 25 parts of bamboo fiber nano-powder, 14 parts of silica nano-particles, 10 parts of tea tree essential oil, 10 parts of gypsum powder, and 10 parts of composite reinforcing glue 4 parts, 4 parts of natural antibacterial factor complex, 2 parts of oil-soluble benzotriazole, 3 parts of softener ES, 4 parts of polydimethylsiloxane and 2 parts of fragrance, the preparation method of this composite fabric is as follows:

[0066] S1: Use lyocell fiber and modal fiber blend to make fabric base layer 2, use bamboo charcoal fiber and polyester fiber warp and weft to weave antibacterial fabric, and cut Gore-Tex fabric for spare;

[0067] S2: Prepare a functional coating layer, as follows:

[0068] S2.1: Dissolve oil-soluble benzotriazole in tea tree essential oil, and use compound reinforcing glue to encapsulate the natural antibacterial factor complex i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com