Super magnetostrictive actuator

A technology of giant magnetostriction and giant magnetostrictive rod, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problem that the driver technology cannot be well satisfied Accuracy requirements, restrictions on the application of magnetostrictive drives, small output displacement of magnetostrictive materials, etc., to achieve the effects of high test efficiency and test accuracy, short test time, and large output force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

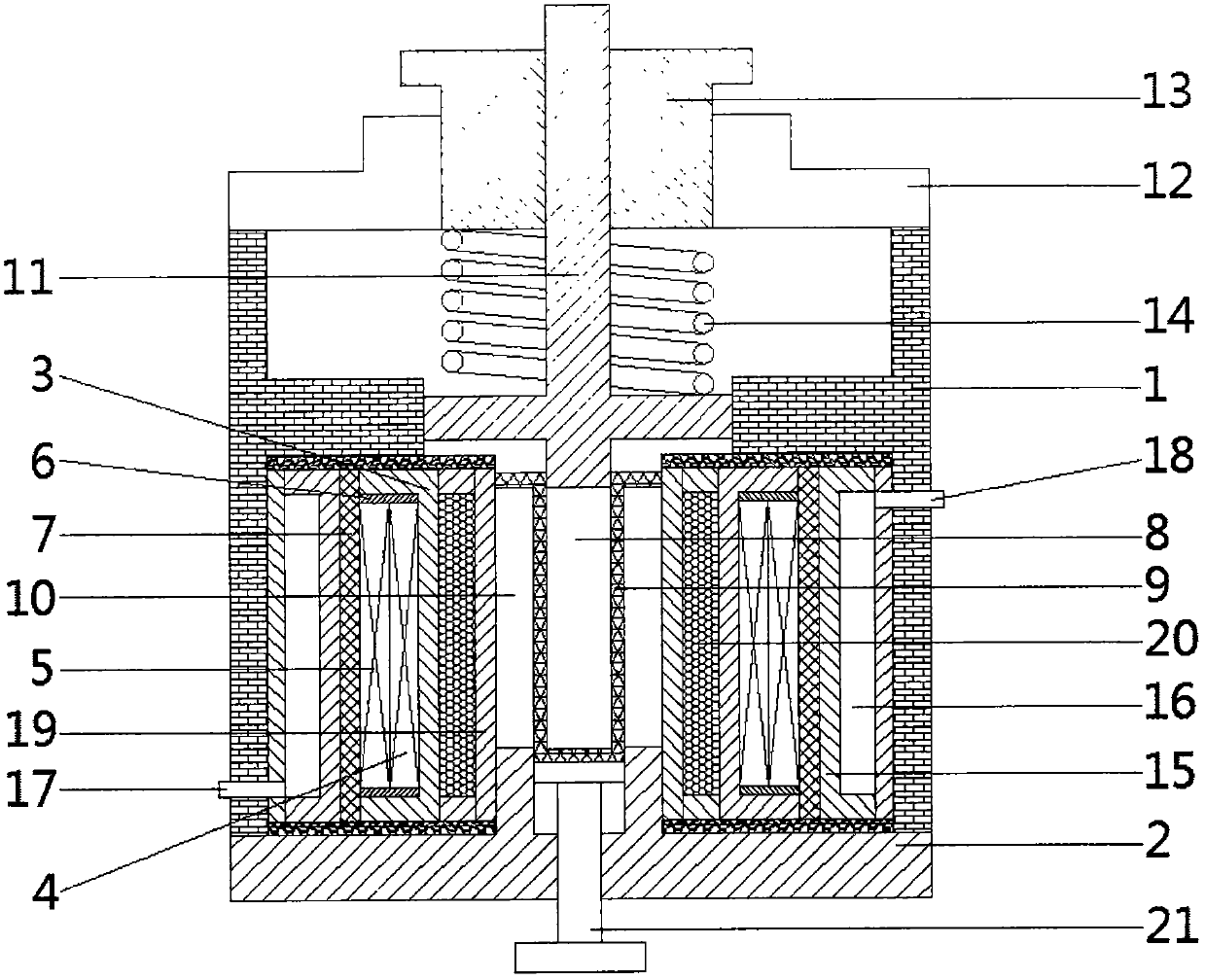

[0025] see figure 1 , a giant magnetostrictive driver, comprising a housing 1 and a base 2 arranged at the bottom of the housing 1, the housing 1 is provided with a magnetic field generating device, a cooling device, a pretensioning device and a positioning device;

[0026] The magnetic field generating device includes a coil bobbin 3 arranged on the lower side of the housing 1 and a permanent magnet 7 arranged outside the coil bobbin 3 , a drive coil 4 is wound outside the coil bobbin 3 , and a drive coil 4 is wound outside the drive coil 4 . A bias coil 5 is connected, and a heat shield 6 is provided at the contact between the inside of the bobbin 3 and the driving coil 4 and the bias coil 5. A cavity is provided in the middle of the bobbin 3 and a U is installed inside the cavity. shaped tube 9, a first giant magnetostrictive rod 8 is placed inside the open end of the U-shaped tube 9, and two second giant magnetostrictive rods 8 are placed symmetrically on the outside of th...

Embodiment 2

[0037] see Figure 1-4 , a giant magnetostrictive driver, comprising a housing 1 and a base 2 arranged at the bottom of the housing 1, the housing 1 is provided with a magnetic field generating device, a cooling device, a pretensioning device and a positioning device;

[0038] The magnetic field generating device includes a coil bobbin 3 arranged on the lower side of the housing 1 and a permanent magnet 7 arranged outside the coil bobbin 3 , a drive coil 4 is wound outside the coil bobbin 3 , and a drive coil 4 is wound outside the drive coil 4 . A bias coil 5 is connected, and a heat shield 6 is provided at the contact between the inside of the bobbin 3 and the driving coil 4 and the bias coil 5. A cavity is provided in the middle of the bobbin 3 and a U is installed inside the cavity. shaped tube 9, a first giant magnetostrictive rod 8 is placed inside the open end of the U-shaped tube 9, and two second giant magnetostrictive rods 8 are placed symmetrically on the outside of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com