Non-contact thermal shock high-temperature mechanical test device

A high-temperature mechanics and testing device technology, applied in measurement devices, using repetitive force/pulse force to test material strength, and using stable tension/pressure to test material strength, etc., can solve the problem of poor interchangeability and adaptability of induction components, Difficulty in material selection and design, difficulty in multi-angle real-time observation, etc., to reduce power consumption and cooling difficulty, increase test flexibility, and reduce mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 Focusing infrared lamp experiment

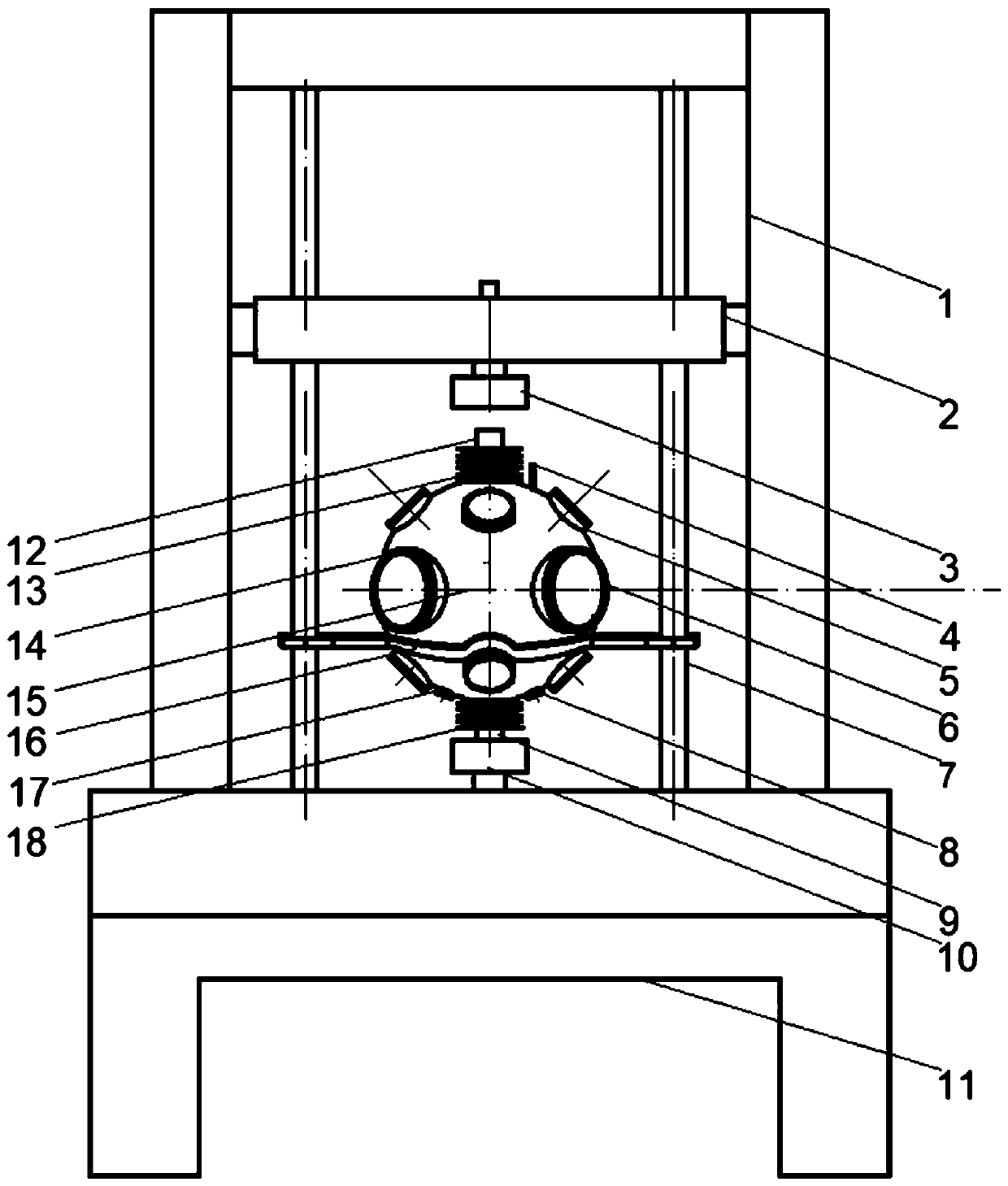

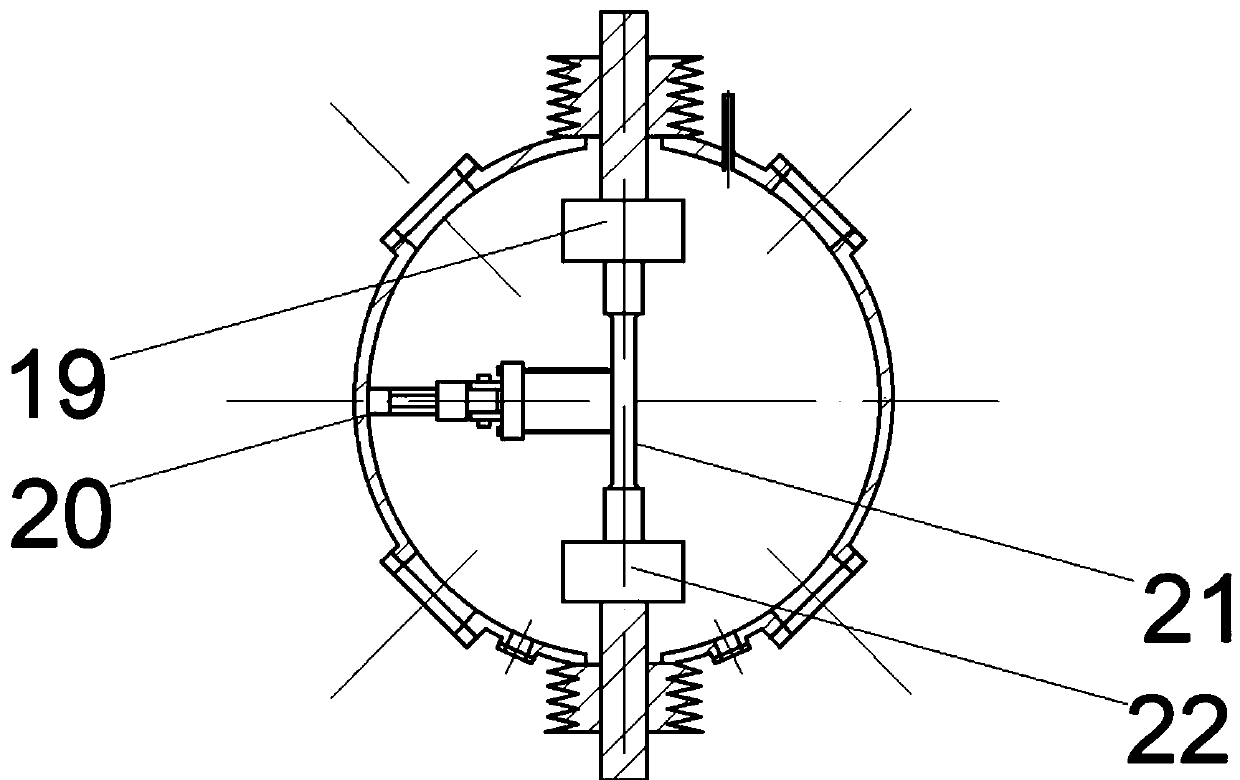

[0034] figure 1 It is a schematic diagram of the overall structure of a non-contact thermal shock high temperature mechanical testing device of the present invention. from figure 1 It can be seen that the non-contact thermal shock high-temperature mechanical testing device includes a base 11 and a mechanical experiment module 1 fixed on the base 11. A cavity is formed between the mechanical test module 1 and the base 11, and a middle beam 2 is arranged horizontally in the cavity. , both ends of the middle beam 2 are fixedly connected with the mechanical test module; two symmetrical guide rails 7 are longitudinally arranged in the cavity, one end of the guide rail 7 is fixedly connected with the mechanical test module, and the other end is fixedly connected with the base 11; the middle beam 2 The lower part of the cavity is fixed with an upper clamp 3 outside the cavity, and the upper surface of the base 11 is correspond...

Embodiment 2

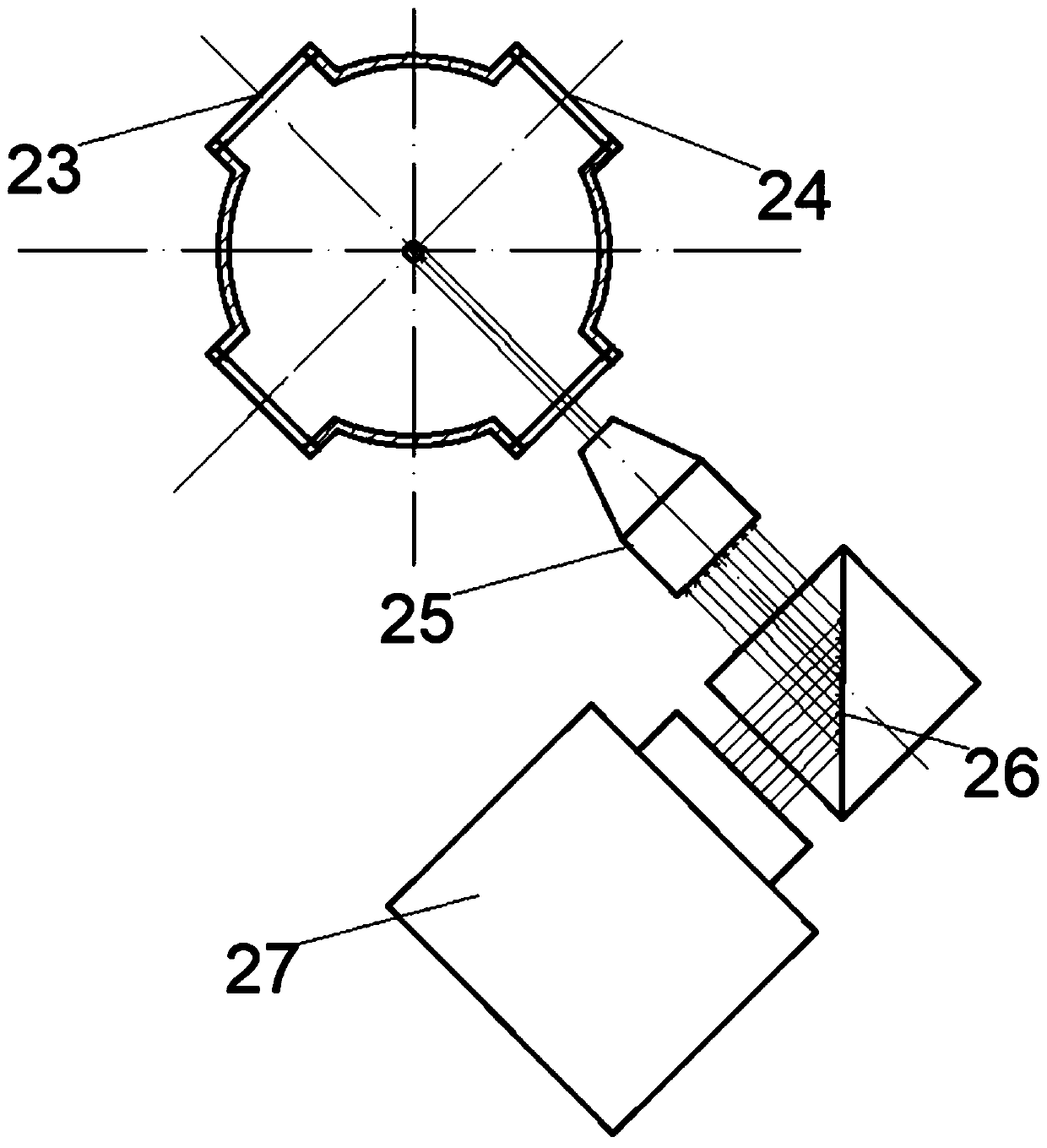

[0051] Embodiment 2 laser experiment

[0052] The difference between this embodiment and embodiment 1 lies in the experimental environment and heating method. After the spherical cavity 15 is vacuumized, open the intake module 17 with a flowmeter, and fill the spherical cavity 15 with argon until the air pressure reaches 10 -2 pa.

[0053] Do not use infrared lamp heating module, only use laser heating module. Turn on the laser heating module 6 , adjust the optical path of the laser in the visible light mode, and adjust the focal length of the laser in the low power state to focus on the test area of the specimen 21 . The laser drive power is remotely controlled by the computer. In the continuous output mode, the laser output power is gradually increased to 600W. At the same time, the temperature of the test piece is monitored by the infrared temperature measuring device 23 and the colorimeter. After reaching 1600°C, the laser maintains the temperature in pulse mode and P...

Embodiment 3

[0055] Embodiment 3 infrared-laser synchronous heating experiment

[0056] The experimental device of this embodiment is the same as that of Embodiment 1, except that the infrared module 5 and the laser module 6 are used simultaneously to heat the test piece 21 in the experimental steps.

[0057] Start the infrared lamp heating module 5, and adjust the focal lengths of the four infrared lamps in a low power state to focus on the test piece 21. Then the laser heating module 6 is turned on, the optical path of the laser is adjusted in the visible light mode, and the focal length of the laser is adjusted in the low power state to focus on the test piece 21 . Afterwards, the infrared module is controlled to heat the sample surface to a constant temperature of 800°C. Then turn on the laser module, gradually increase the output power, and use the infrared temperature measurement and colorimeter feedback to make the temperature of the sample area reach an ultra-high temperature stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com